Aluminum Processing Team

Can be manufactured around

the clock, 7 days a week.

Can be manufactured around

the clock, 7 days a week.

Typ

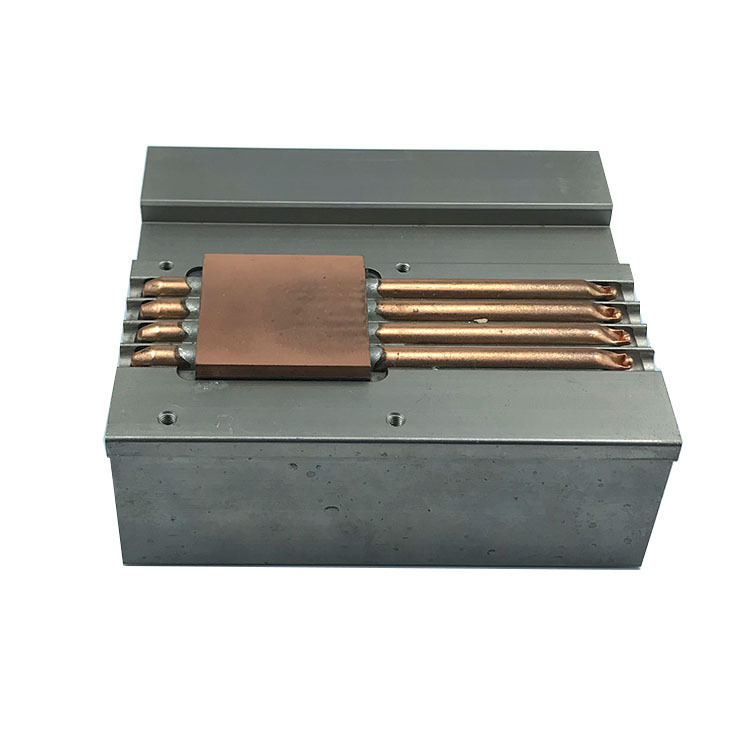

Heatpipe Assembly Heat sink

Process

Bending/Flattening/Brazing

Extra Process

Extrusion/Skiving+CNC Machining

Material

Al1060、 Al 6061、Al6063、Cu1100、Cu1020

Size/Color

customized

Surface treatment

Sandblasting, Wire Drawing, Painting, Electroplating, Anodizing

Quality Control

full inspection

Application

Mechanical Equipment、Source、Electronic Devices

OEM

Accept

Key points of Heat pipe Assembly heat sinks design

The heat transfer performance of heat pipes is indeed very powerful, but to better play its role, it still needs to rely on the precise matching of the basic modules, fins, and other components.

1、Heat pipe selection: Heat pipes with different capillary structures have certain differences in heat transfer performance. In practical applications, forming processes such as bending and flattening need to be carried out to meet the heat dissipation needs of different heat sources. In addition, the diameter, length, and assembly direction of heat pipes can also affect their heat transfer performance.

2、Heat sink production and assembly: usually paired with heat pipes, stamped and toothed heat sinks are used. The thickness, length, spacing, arrangement of heat sinks, connection process between Fin and heat pipes, penetration of Fin, reflow soldering, etc. all affect the overall heat dissipation performance.

3、Module welding: The substrate, heat pipe, and heat sink are finally combined by welding. The flatness of the substrate, the connection between Fin sheets and the substrate and heat pipe, and the welding between heat pipes and substrate will all generate additional thermal resistance.