目标并竭力推动您的项目效益提升

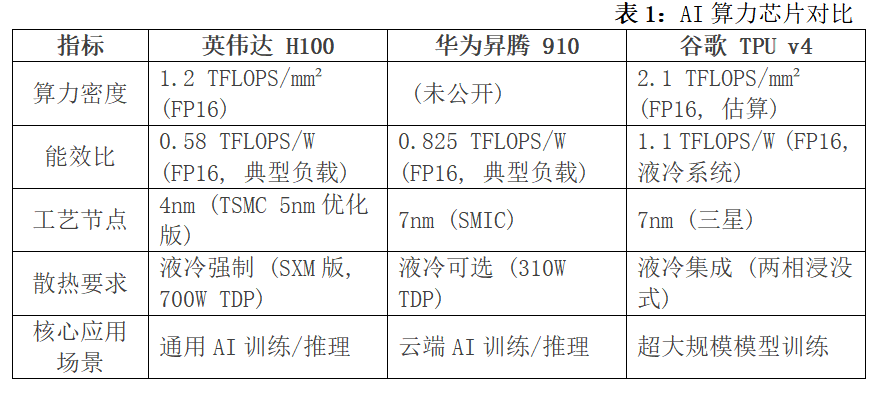

在通往百亿亿次(Exascale)AI算力的道路上,华为的CloudMatrix 384超节点与NVIDIA的GB200 NVL72集群,已成为全球瞩目的两座技术高峰。它们不仅代表着不同的硬件集成能力,更深刻地揭示了两种构建超级计算系统的根本性哲学。

一个被比喻为“持续高烧”,面对的是384颗芯片稳态运行下、密不透风的极限散热挑战;另一个则被形容为“间歇性癫痫”,需要驯服72颗顶级GPU同步工作时产生的剧烈脉冲热流。这两种不同的“病因”,最终指向了截然不同的“药方”——即散热解决方案,并为我们清晰地展现了两种核心工程哲学:确定性系统工程与敏捷性生态创新的对决。对于身处其中的每一家供应链企业,理解这场对决,是定义自身未来角色的关键。

1-核心差异的根源——“病因”决定“药方”

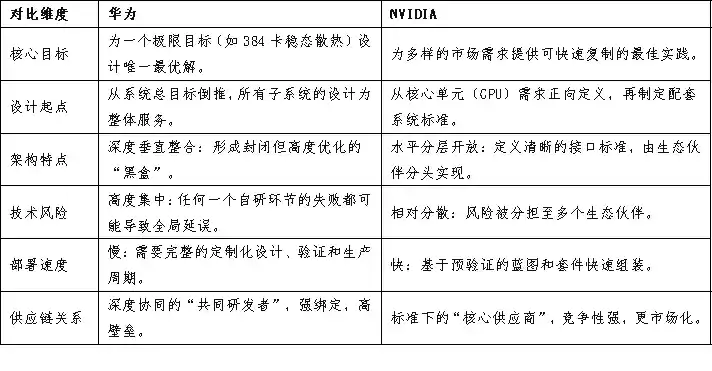

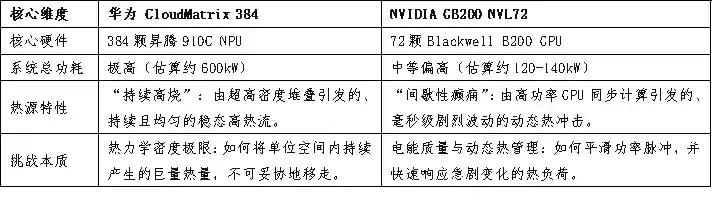

在设计起点上,华为与NVIDIA就走向了不同的道路,这直接塑造了它们迥异的热源特性:

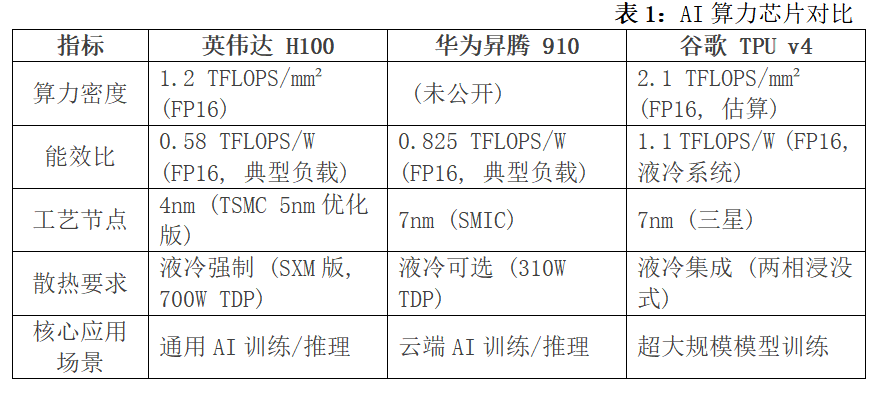

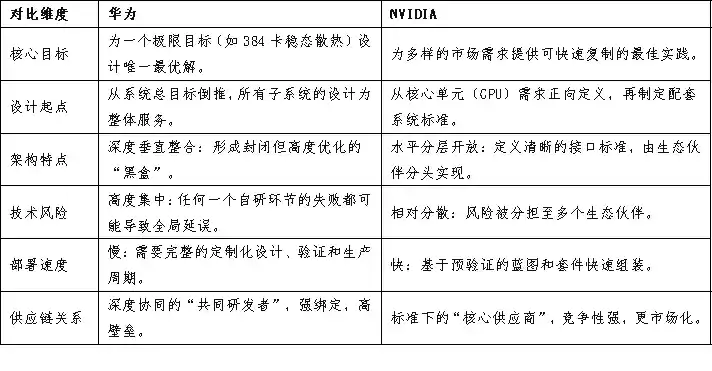

表1:两种技术路线热源特性对比

这种“持续高烧”与“间歇性癫痫”的差异,绝非偶然。它反映了华为作为挑战者,选择以系统总性能为核心进行攻坚,不惜代价在单机柜内实现算力密度的极限突破;而NVIDIA作为领导者,其任务是在保证单芯绝对性能优势的同时,构建一个能高效协同并易于普及的生态系统。

2-工程哲学的物化——两种液冷路径

两种不同的设计哲学,在关键的液冷方案上得到了最集中的体现,塑造了从芯片到机房的完整技术栈。

a. 华为:确定性系统工程的液冷实践

这是一种自上而下、为系统级确定性目标而生的设计哲学。其核心是将散热作为基础设施的关键部分进行全局一体化、高可靠性的工程实现,而不仅仅是配套部件。

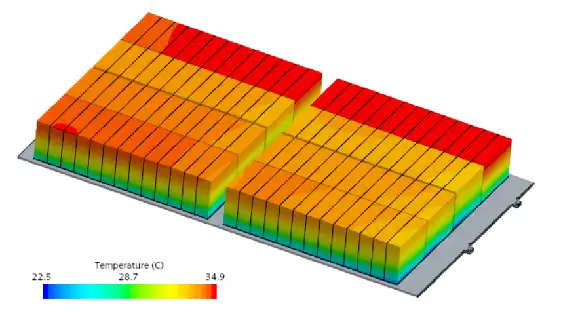

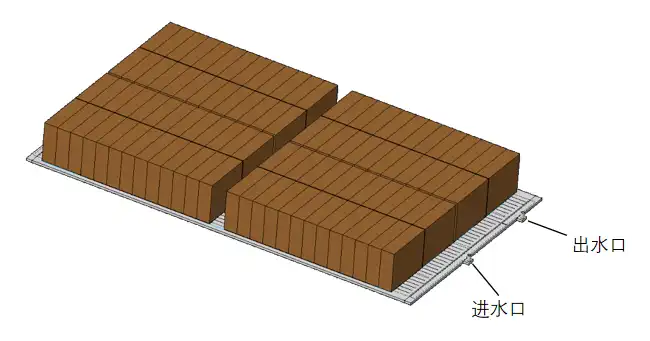

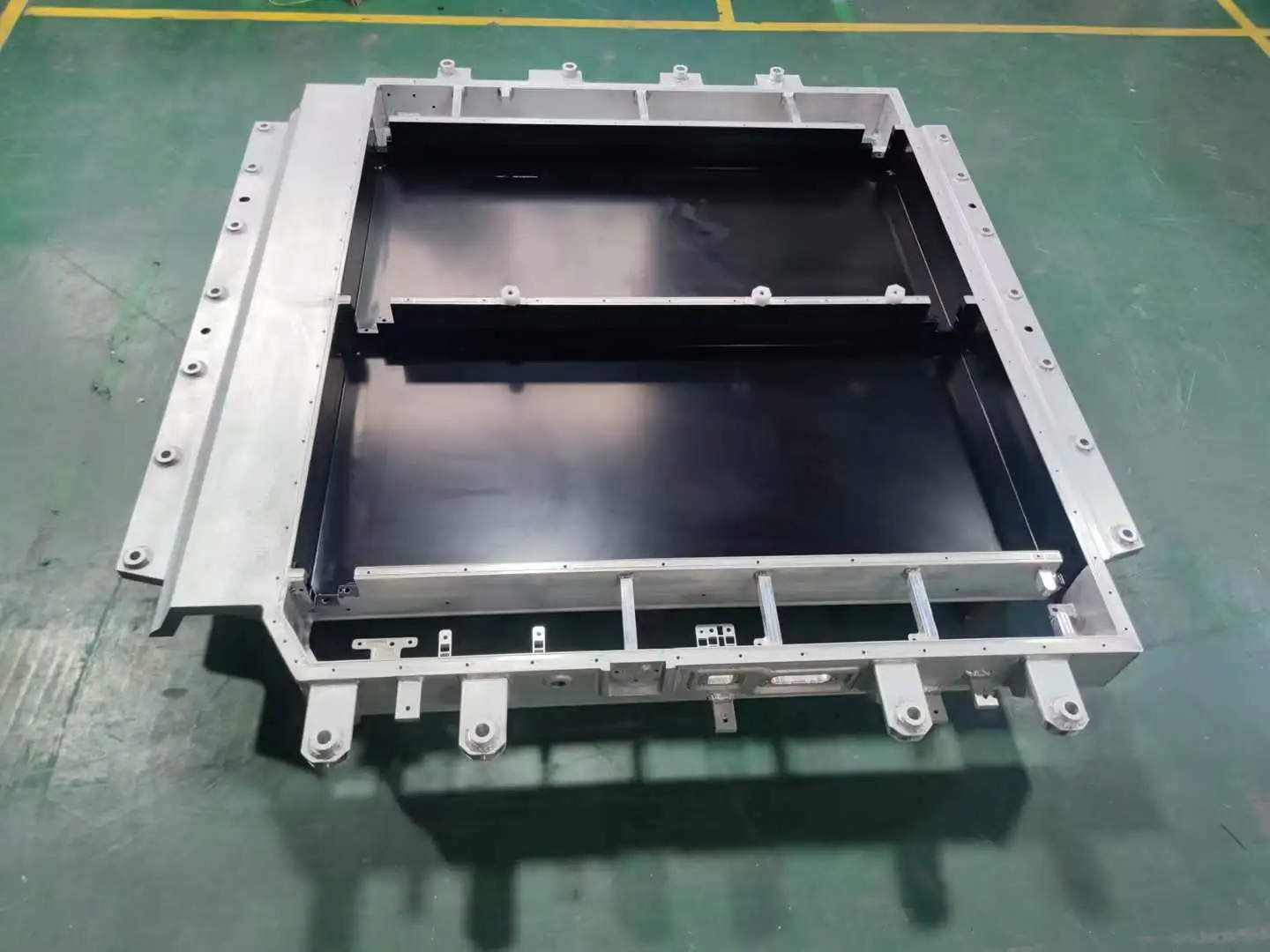

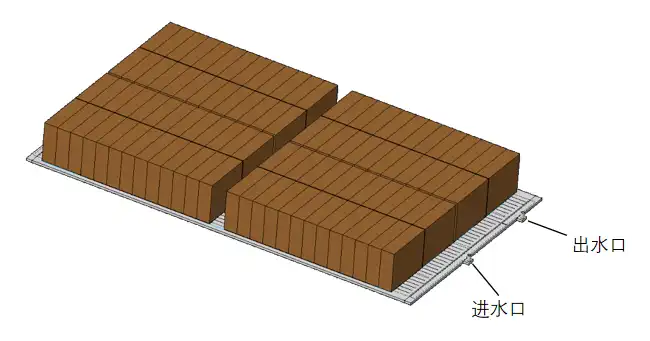

图1:华为昇腾 384 超节点

· 芯片级精工与可靠连接:为确保芯片热量高效传递至冷板,华为聚焦于界面材料的工程优化。虽然公开资料显示其在该领域(如高球形度碳化硅填料)有前沿专利储备,但其在超节点中的具体应用方案并未公开。可以确定的是,其方案必然追求极低的界面热阻和长期可靠性,以应对“持续高烧”的挑战。

· 系统级冗余与智能控制:采用如环形供液等冗余设计,并自研液冷热管理控制器(TMU) 作为系统“中枢”。该控制器能实现管路间0秒切换,并通过AI进行故障预测,以软件定义的方式保障散热链路的确定性与可靠性,这是其系统工程思维的典型体现。

· 基础设施融合(“冷电融合”):在机柜层面,将液冷分配单元与高压配电单元进行物理集成与统一管理。这种“冷电一体”的设计,是应对单柜超高功率密度、简化部署和提升能效(降低PUE)的终极工程响应,是其确定性设计从理念到物理形态的落地。

b.NVIDIA:敏捷性生态创新的液冷框架

这是一种以GPU为核心、通过定义开放标准赋能全球生态的设计哲学。其核心是提供一套经过验证的“蓝图”,降低全行业的应用门槛,实现高效、灵活的规模化部署。

· 芯片级标准化与参考设计(VRD):NVIDIA为GPU(如Blackwell系列)提供详细的散热参考设计,明确定义冷板的物理尺寸、热设计功耗(TDP)、流量与压降等性能接口。这等于为所有散热厂商提供了“标准答案”,将复杂性封装在标准件内,确保了基础组件的兼容性和质量基线。

· 生态级协作与方案认证:与Vertiv、Boyd等顶级热管理及基础设施厂商深度合作,共同开发并认证机柜级液冷解决方案。例如,Vertiv的 Tier 2 Ready 机柜方案就是基于NVIDIA蓝图开发的预验证产品,使数据中心运营商能够像采购标准设备一样,快速获得即插即用的液冷集群。

· 数字孪生赋能与部署加速:通过NVIDIA Omniverse平台,提供数据中心液冷系统的数字孪生和仿真工具。客户可以在虚拟环境中对散热方案进行设计、验证和优化,极大降低了实体验证的成本与风险,实现了从设计到部署的敏捷化。

为了更清晰地理解这两种路径,我们将其核心差异对比如下:

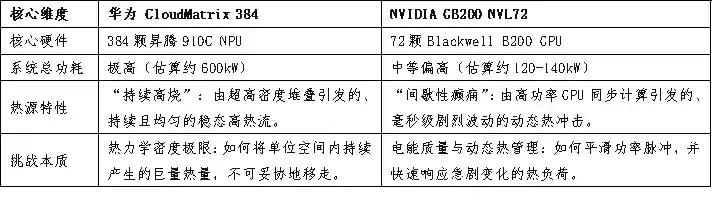

表2:华为模式 vs. 英伟达模式:关键差异一览

3-历史的启示与未来的融合

这两种路径的竞争,在科技史上并非孤例。它本质上是系统整合式创新与平台生态式创新的又一次经典演绎。华为像当年的乔布斯时代的苹果,追求对产品体验从顶层到底层的绝对掌控;而NVIDIA则更像如今的谷歌Android,通过制定核心标准(Android系统/GPU架构)来驱动整个生态的繁荣。

对于行业而言,未来的趋势并非一方彻底取代另一方,而是可能出现一定程度的融合:

· 在追求极致算力的国家或企业级项目中,“确定性系统工程”的魅力依旧不减。

· 在广阔的商业化云计算市场,“敏捷性生态创新”将因其速度和成本优势持续扩张。

· 智慧的火花可能诞生在交叉地带:在开放的生态标准中,融入更深度的定制化与协同优化。

4-结语

因此,华为与NVIDIA的散热之争,本质是AI时代两种核心竞争力的对垒:一方追求通过系统工程的深度整合,实现确定性的极致性能;另一方则通过构建开放标准与生态,驱动产业的敏捷创新与快速普及。这场对决为产业链上的参与者划出了清晰的路径选择:是作为“特种部队”,深入绑定,攻克具体的系统级堡垒;还是作为“主力军团”,融入生态,在广阔的标准平原上开拓市场。最终,胜负不仅在于技术本身,更在于对产业演进逻辑的洞察,以及对自身在未来蓝图中位置的明确定位。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

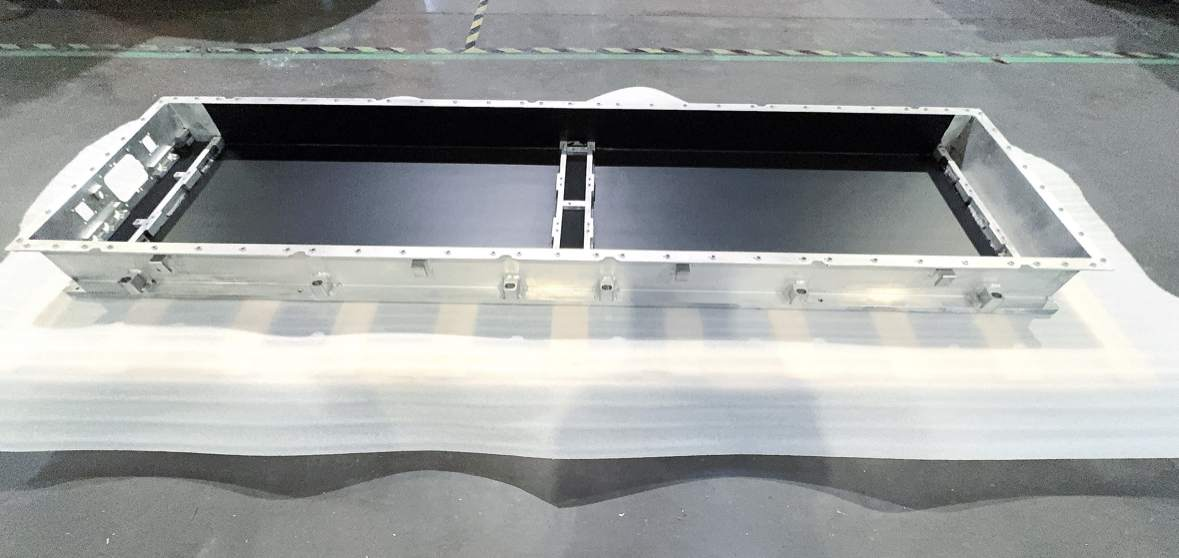

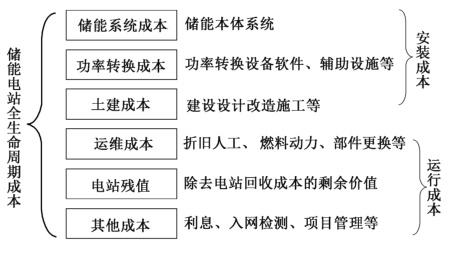

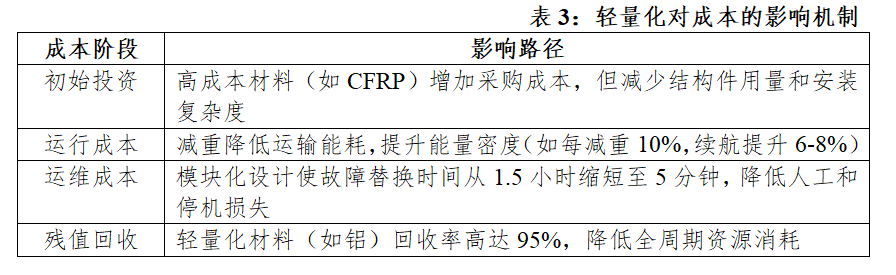

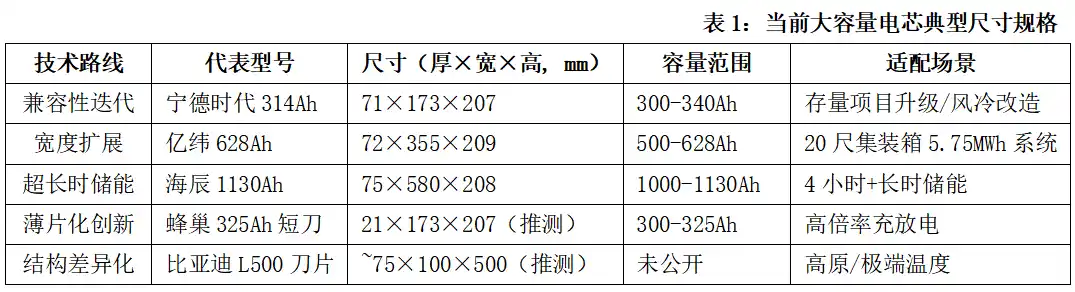

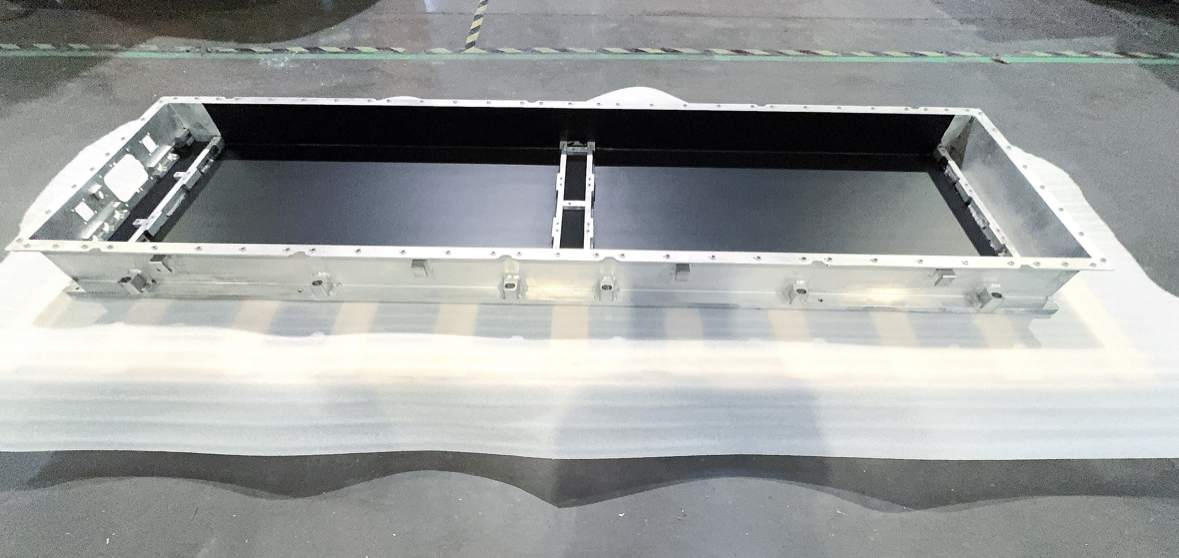

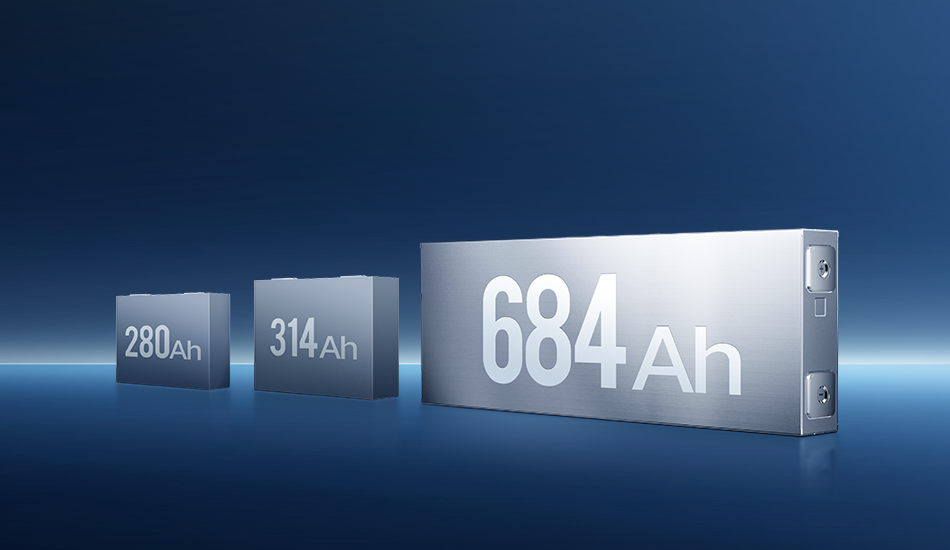

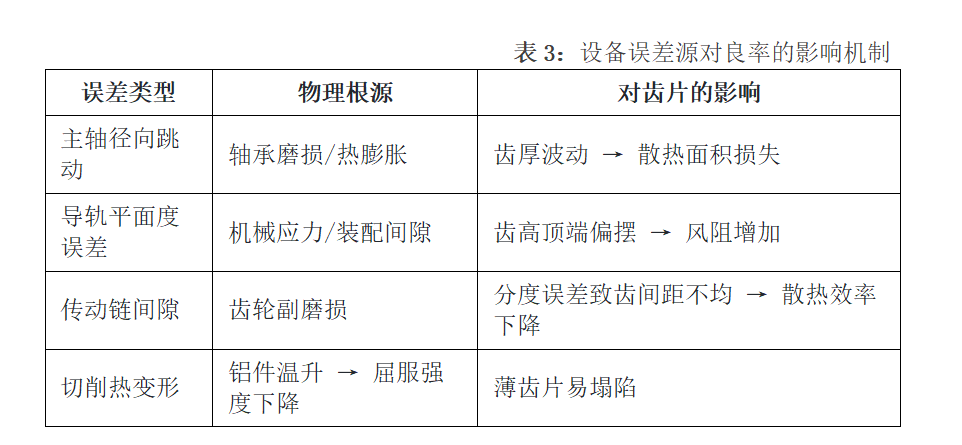

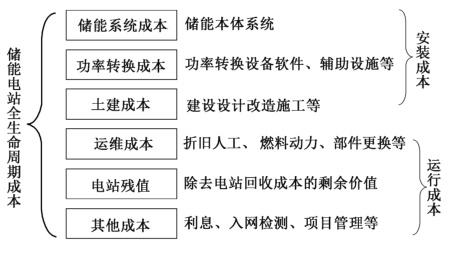

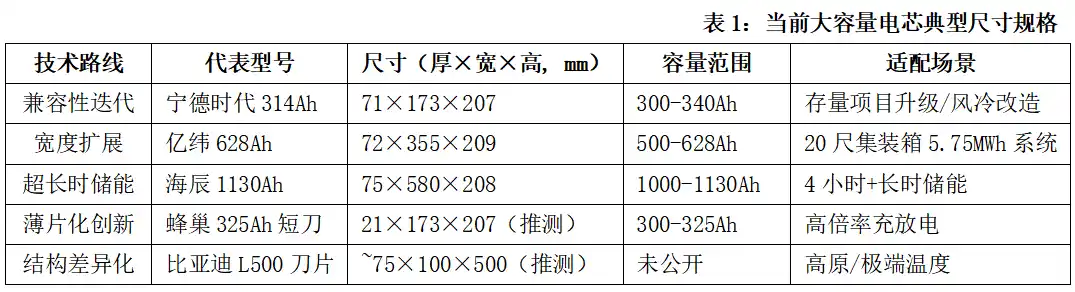

当电芯的“大”成为共识,Pack的“强”成为新战场

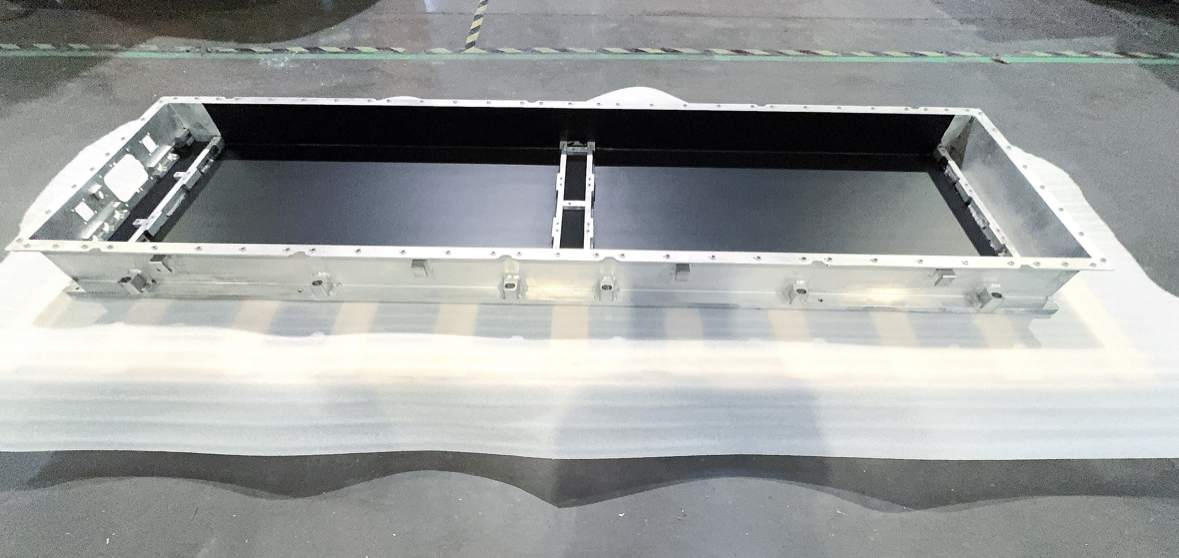

储能行业正迎来电芯容量跃升的时代,从280Ah迈向500Ah+已成为进行中的现实。当行业聚焦于电芯的“大”时,Pack的“强”——即其机械结构承载与安全化解能力——正成为新的竞争焦点。无论电芯化学体系与容量如何演进,其膨胀力、热失控能量与机械载荷,最终都需由Pack下箱体这一机械基础来承担。

本文将从结构设计的角度,探讨在电芯技术路线分化的背景下,Pack下箱体如何应对差异化的机械与热管理需求,并构建可持续适配的工程能力。

1-三大技术路径的机械解析:载荷、热与空间的三角难题

电芯容量的提升,直接改变了Pack系统设计的边界条件。下箱体作为系统的“骨架”与“皮肤”,需要重新回答三个基础问题:

a. 对587Ah(高集成路径)的力学解析

核心诉求:在标准20尺集装箱内实现≥6MWh的能量密度,催生了“共4列8簇”等极致紧凑布局。

下箱体挑战:

· 结构承载优化:在整体质量增大而支撑点减少的情况下,箱体需优化传力路径,兼顾整体刚度与关键区域的局部强度,以保障运输与运行中的结构稳定。

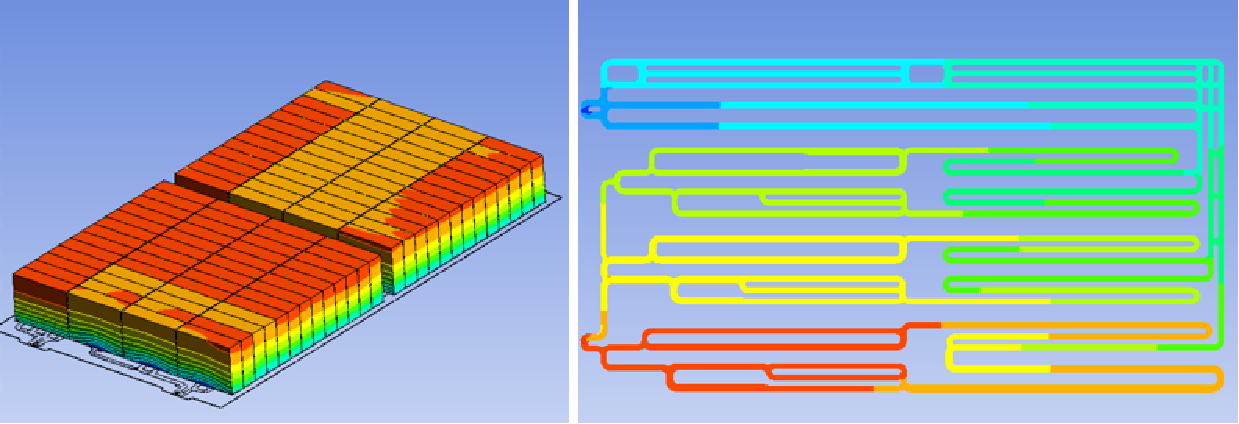

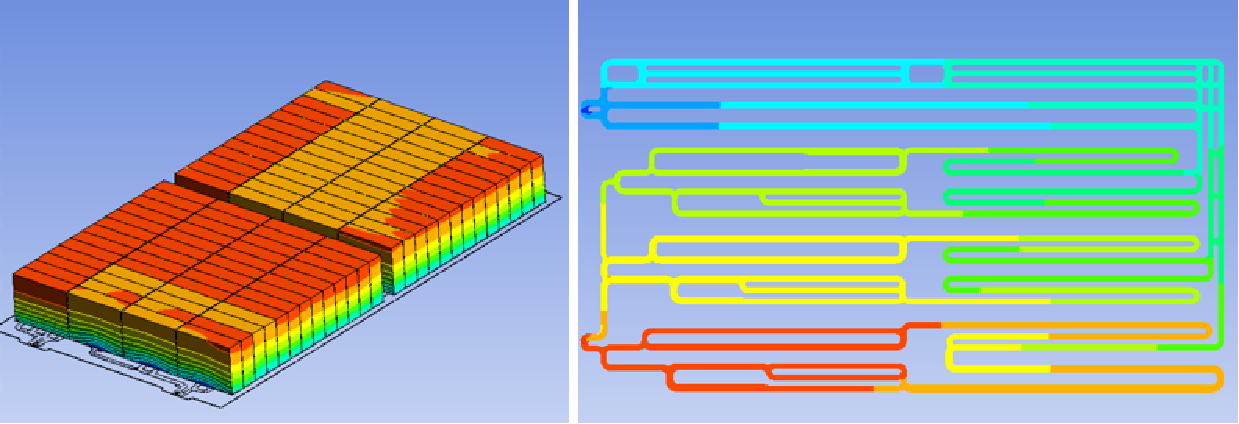

· 热管理结构融合:液冷系统与箱体底板及支撑结构深度集成,既作为热管理核心,也参与整体承力。设计需确保在长期结构载荷与热循环下,冷却密封的持久可靠。

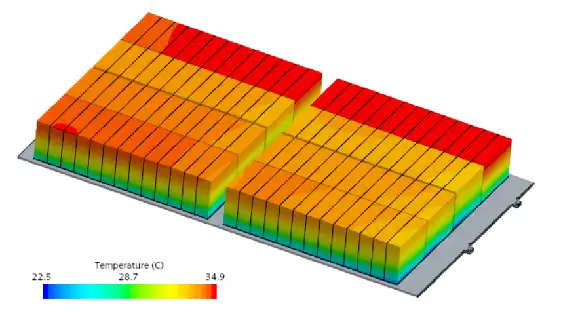

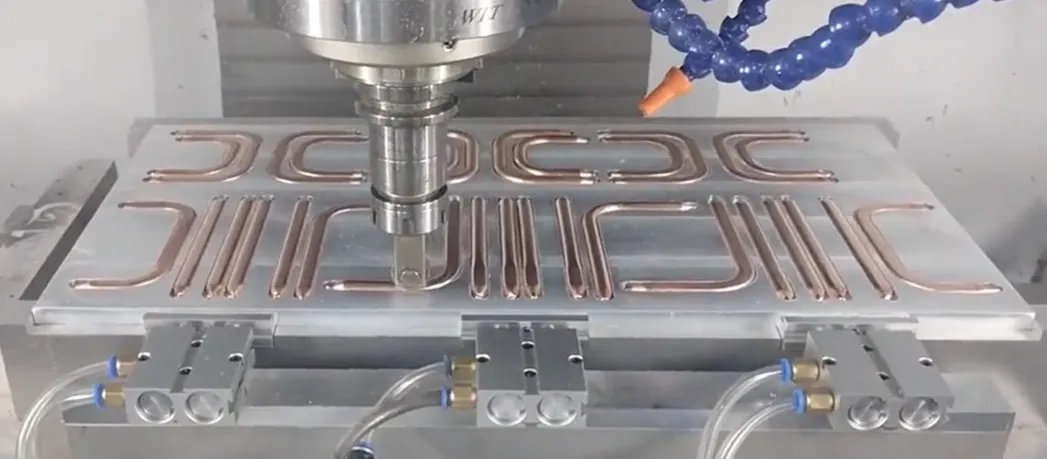

储能Pack下箱体仿真

· 空间精确协调:箱体须在有限空间内为电芯膨胀、电气连接热位移及消防管路等预留合理间隙,实现各子系统在紧凑布局下的可靠共存。

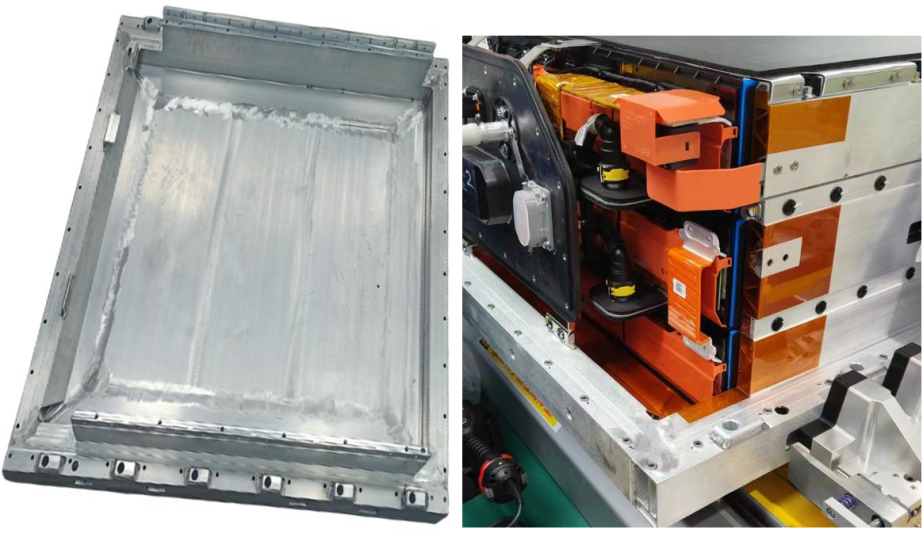

b.对684Ah(超大容量路径)的热力与结构对应分析

核心诉求:通过单电芯容量最大化来降低单Wh成本,但带来了物理层面的集中化效应。

下箱体挑战:

· 膨胀力的“焦点”效应:单个电芯的膨胀力与容量并非线性关系,而是接近指数级增长。箱体内部框架需设计更强大、更均匀的“束缚系统”,将集中的膨胀应力分散至整个箱体,避免局部塑性变形。

· 热管理的“均匀性”困境:更大的发热体需要更高效的导热路径。下箱体的底板材质、厚度、与电芯底部的接触界面设计(如导热垫的压缩率设定)变得至关重要。热失控时,更大的能量释放对泄压通道的定向导流能力和内部防火隔断的阻燃时效提出了更高要求。

· 重量集中的结构响应:更重的单电芯改变了Pack整体的振动模态,下箱体需重新进行疲劳仿真,防止在特定频率下发生共振导致的连接件松动或结构开裂。

c.对392Ah(稳健过渡路径)的制造适配说明

核心诉求:侧重于在性能、成本与交付效率之间取得平衡,为市场提供经过充分验证的解决方案。

下箱体挑战:

· 成熟方案的稳定实现:基于已验证的设计与工艺体系,通过严格的制程控制确保产品一致性,支撑快速、稳定的量产节奏.

· 供应链的深度协同:依托成熟的供应体系,通过材料选型、工艺优化与规模化采购,持续提升产品的综合成本竞争力。

2- 应对分化的工程思维:

面对多条技术路线,下箱体供应商无法为每条路径重建技术体系。真正的解决方案在于平台化的精准响应——以可扩展的模块化设计,高效适配不同需求。

a. 聚焦共性的物理原理与协作模式

电芯迭代遵循稳定的物理规律。我们基于核心参数建立协同评估流程,结合材料与结构数据,快速研判新电芯可行性,早期识别匹配风险,帮助收敛设计方向,减少后期反复。

587Ah储能Pack下箱体

b.构建“标准接口 + 可配置模块”的弹性体系

为应对技术路线分化带来的定制化需求,我们建立了清晰的接口标准化与内部模块可配置的设计体系:

· 统一对外接口:箱体与储能集装箱的安装定位、电气贯穿接口、冷却系统对接点等,均严格遵循行业常见规格,确保系统层面的兼容性与装配一致性。

· 可配置内部结构:我们提供系列化的内部支撑组件与热管理集成方案,可根据电芯尺寸与排布方式灵活组合。

· 热管理集成模块:热管理模块采用模块化设计,以优化温升控制与电芯均温性为核心,可灵活适配不同技术路线的热管理需求。

c.推行“制造即设计”的柔性产线

为匹配技术路线的多样化,我们的制造体系围绕可扩展的基础平台与模块化装配进行组织:

· 基础箱体平台制造:确保主体结构的精度与一致性,为不同配置提供可靠载体。

· 模块化装配单元:支持根据电芯尺寸与排布方式,灵活选用相应的内部支撑与热管理模块进行装配。通过这种布局,我们能够在同一产线上高效完成不同技术路线产品的生产切换,协助客户应对多路线并行开发带来的供应链与交付挑战。

3-下箱体价值的重新定义:从被动承载到主动赋能

下箱体正从被动容器转向系统关键赋能部件,直接影响安全、能量密度与全生命周期成本:

a.安全承载结构:通过为系统级泄压与防火隔断提供可靠的结构通道与安装基础,与热蔓延控制共同构建多级安全防护。

b.能量密度支撑:轻量化、高强度设计减少自身重量与空间占用,为电芯与冷却系统留出更多性能余量。

c.长期可靠性保障:结构完整性与疲劳耐久设计,支撑系统应对长期循环、运输振动等持续挑战。

4-结论:在分化的上游与确定的下游之间,构筑桥梁

随着电芯技术演进,储能系统持续追求安全、高密度与低成本。下箱体需提供可靠且适配的支撑基础,以模块化及柔性制造应对不同技术路线。行业竞争正转向系统级工程,Pack箱体是其中的关键一环。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

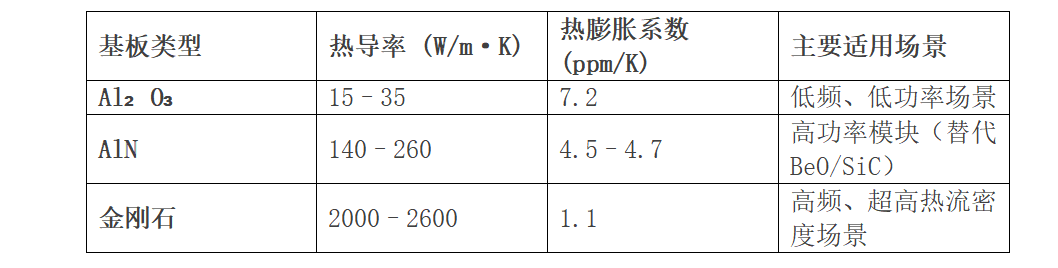

在数据中心发展的数十年间,风冷技术始终是主流选择。然而,英伟达GB200系列产品的推出,正将这个平衡彻底打破。当计算密度达到新的高度,传统的散热方式已无法满足需求,液冷技术正式从幕后走向台前,成为支撑AI算力的关键基础设施。

1-需求端的根本性转变

a.功率密度突破临界点

GB200 NVL72机柜的功率密度预计将达到30kW/柜以上,这个数字远超传统风冷技术15-20kW的散热极限。这意味着:

· 技术路线的必然选择:液冷从“值得考虑”变为“唯一选择”

· 市场空间的质变:每个GB200部署都意味着确定的液冷需求

· 价值量的大幅提升:单个机柜的液冷系统价值达到数十万元级别

b.可靠性要求升级

随着单机柜算力密度的提升,其承载的业务价值也呈指数级增长。液冷系统的可靠性直接关系到:

· 业务连续性:一次散热故障可能导致数百万的算力损失

· 系统寿命:温度每升高10℃,电子元件寿命减半

· 性能稳定性:散热效率直接影响芯片能否持续维持峰值性能

2-技术要求的全面提升

a.散热效率的阶跃需求

GB200对散热系统提出了前所未有的要求:

· 导热性能倍增

· 冷板导热系数需要达到传统方案的3-5倍

· 接触热阻要求降低一个数量级

b.流量精度控制

· 需要实现±1%以内的流量控制精度

· 支持动态流量调节,适应不同负载工况

c.温度均匀性

· 芯片表面温差需控制在5℃以内

· 避免局部热点影响系统稳定性

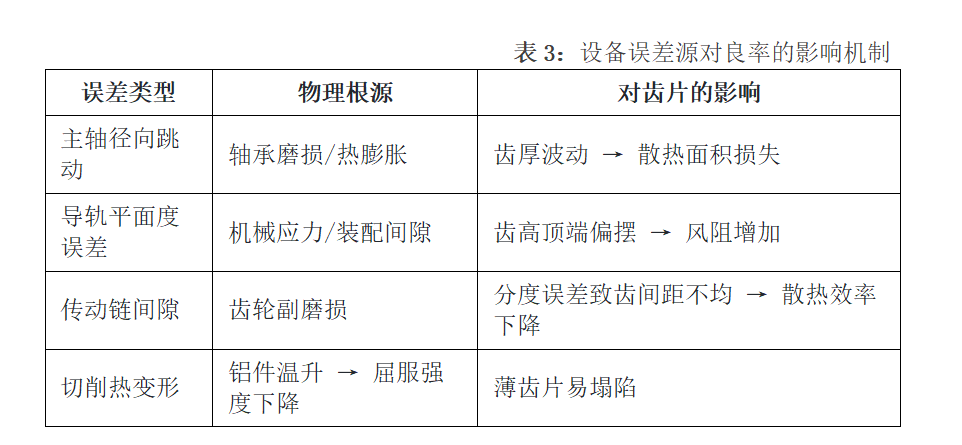

3-系统集成复杂度的跃升

液冷系统已从简单的部件供应,发展为复杂的系统工程:

a.传统模式:

· 提供标准化冷板

· 简单的管路连接

· 基础监控功能

b.GB200时代:

· 机柜级液冷架构设计

· 智能流量分配系统

· 实时健康状态监测

· 预测性维护能力

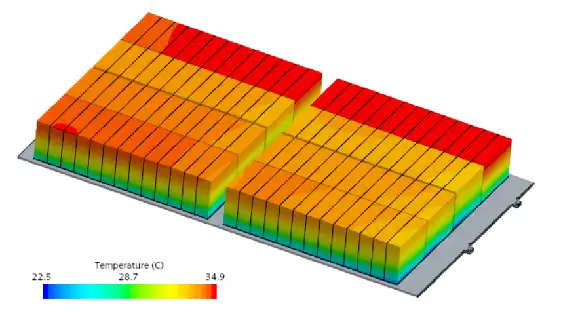

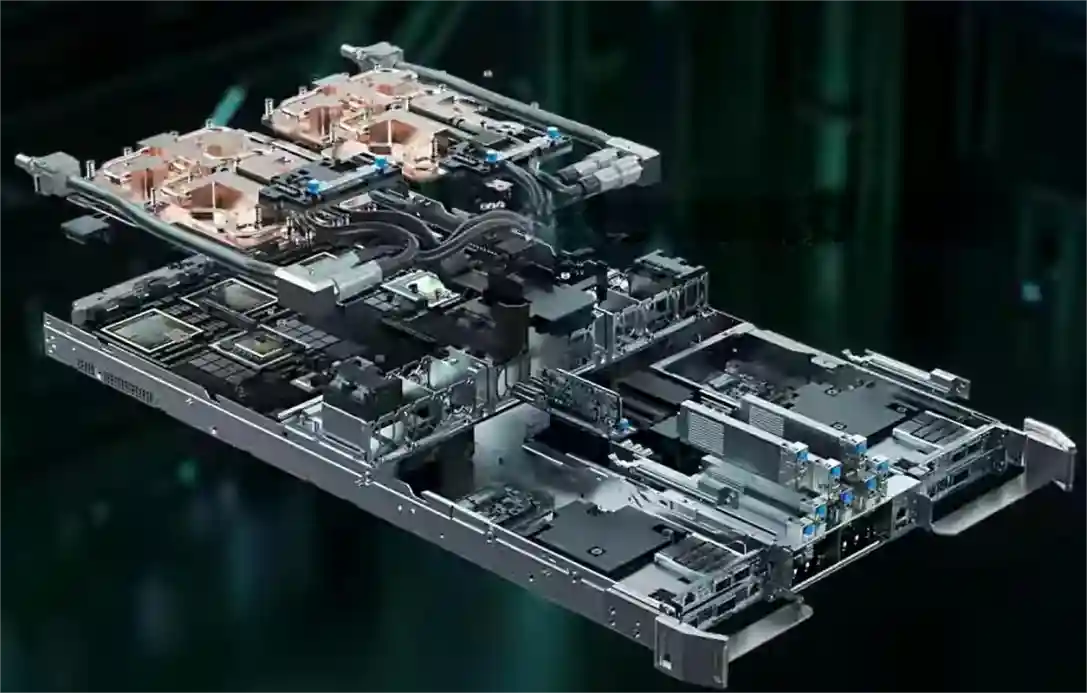

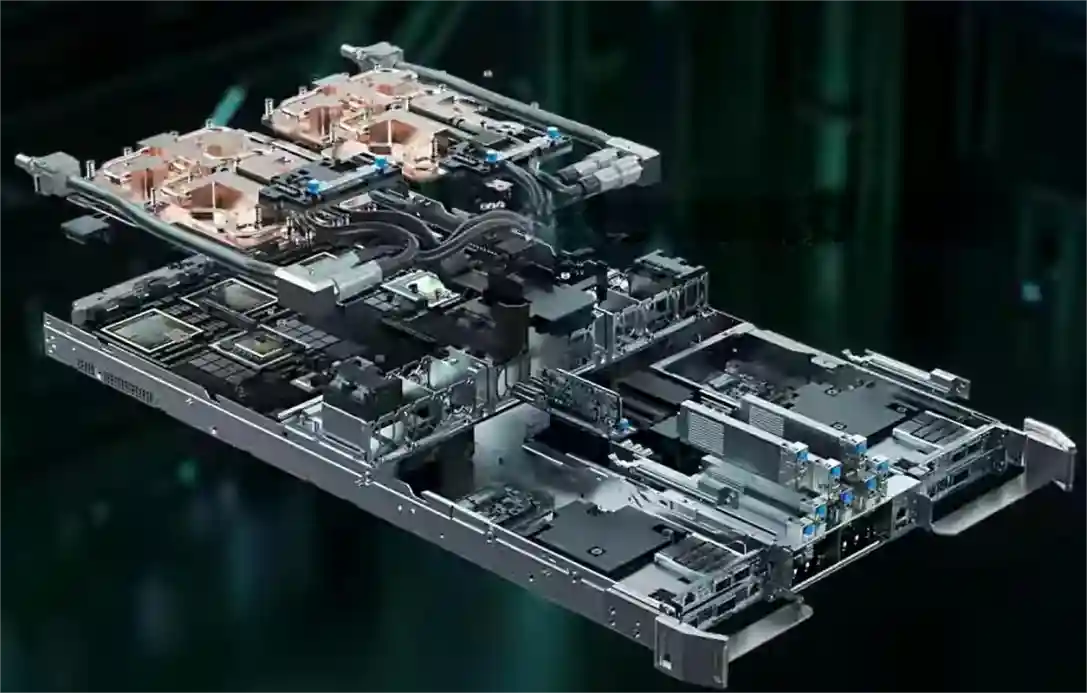

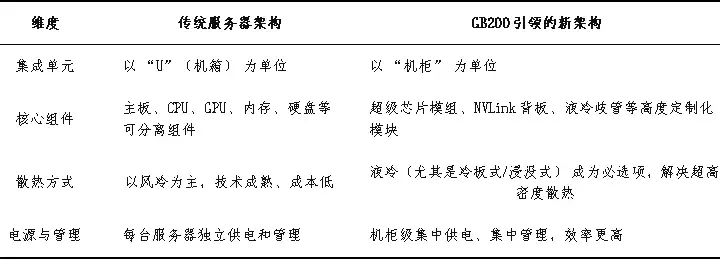

图2-英伟达GB200机柜

4-竞争壁垒的全面提升

在新的市场环境下,企业需要跨越更高的门槛:

a.技术壁垒

液冷企业必须突破单一学科的限制,构建跨领域的综合技术体系。微通道设计、材料科学与流体力学等多学科技术的深度融合成为基础门槛,而芯片级的热仿真与优化能力更是考验着企业的深层技术积累。这已不再是简单的工艺改进,而是需要长期研发投入的系统性工程。

b.认证壁垒

行业认证体系正变得日益严苛。企业不仅要通过服务器厂商制定的严格可靠性测试,还要获得芯片原厂的技术认证。这种双重认证要求不仅验证产品的技术性能,更考验企业的质量体系和持续稳定供货能力,成为进入核心供应链的必备通行证。

c.服务壁垒

随着液冷系统升级为核心子系统,服务能力已成为关键竞争要素。企业需要建立覆盖全国的快速响应网络,并构建7×24小时的专业运维体系。这种服务能力不仅要求技术支持的及时性,更需要预防性维护和应急处理的全流程服务解决方案,真正成为客户可信赖的合作伙伴。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

在计算架构的演进史上,某些时刻的到来并非悄无声息。英伟达GB200 NVL72的推出,就是这样一个时刻——它不仅仅是一款新产品,更是一次对服务器概念的彻底重构。

三十年来,“服务器”始终意味着一个标准化的机箱单元:内部是主板、CPU、内存、硬盘和扩展卡,通过行业标准接口互联。我们以“U”为单位衡量它,在机柜中堆叠它,通过网络连接它。然而,GB200 NVL72的出现,正将这一稳固的定义从核心处瓦解。

它的本质不再是“一台服务器”,而是一台以整个机柜为形态的“计算机”。传统的服务器组件被解构,然后在更大的尺度上,通过NVLink-C2C、液冷散热和机柜级供电管理,被重新集成为一个不可分割的计算整体。这不再是简单的升级,而是一场深刻的范式转移。

1-什么是“服务器”?这个问题的答案正在改变

三十年来,我们理解的服务器是一个标准化的机箱:里面有主板、CPU、内存、硬盘、扩展卡,所有组件遵循着行业标准,可以随意替换和升级。

但GB200的改变是根本性的:

· 计算核心不再是独立的CPU和GPU,而是GB200超级芯片——一个将CPU和GPU深度集成的整体

· 互联不再依赖标准的PCIe插槽,而是定制化的NVLink背板

· 散热不再是可选配件,而是集成的液冷系统

· 基本的部署单元从“机箱”变成了“机柜”

传统服务器的各个组件被“撕碎”,然后在机柜这个更大的尺度上重新整合。这不是进化,而是重构。

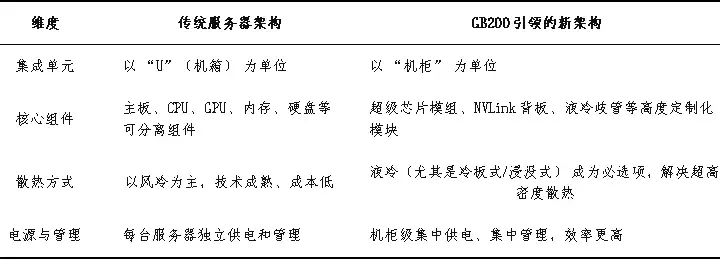

表1-物理架构的重塑:从“机箱”到“机柜”

2-“机柜级体系架构”的三大支柱

传统的服务器设计,是在一个封闭的机箱内进行平衡与妥协。而GB200代表的机柜级体系架构,则是在一个全新的维度上,将散热、互联、供电与管理视为一个完整的系统进行顶层设计。这不再是组件的堆叠,而是系统级的深度融合。其背后,依赖于三大核心支柱的协同创新。

支柱一:从“网络互联”到“背板总线”

在传统数据中心中,服务器是独立的节点,通过网络(如以太网)进行通信。而在GB200 NVL72中,机柜内部的NVLink Fabric在角色上已经取代了传统主板上的总线,成为连接所有计算单元的“骨架”。这种改变使得机柜内的72个GPU能够像一个巨型GPU一样协同工作,通信带宽和延迟得到了数量级的优化。

支柱二:散热从“配套设施”升级为“核心子系统”

当计算密度从每机柜数十千瓦迈向上百千瓦时,传统的风冷技术已无计可施。液冷不再是一个可选的“配套设施”,而是成为了与计算、互联并列的核心子系统。其设计直接决定了整个系统的性能释放与运行稳定性,是从“可用”到“高效能”的关键。

支柱三:管理与供电的“集中化与重构”

GB200采用了机柜级的集中供电与管理。这不仅是追求电源转换效率的提升,更是对系统耦合度的重新定义。它带来了更简化的布线和统一的管理视图,但也将故障域从单个服务器扩大至整个机柜,对运维提出了全新的范式要求。

3-价值链的重构与转移

GB200所代表的“机柜级体系架构”,其影响力早已超越技术本身,正清晰地勾勒出一条新的行业价值链曲线。传统的价值分布正在被打破,新的价值高地则在系统级集成与软硬件协同处悄然形成。

服务器厂商:从“定义者”到“集成者”的战略转型

传统的服务器巨头,如戴尔、HPE,正面临其核心价值的迁移。它们曾经赖以生存的能力——主板设计、系统优化与标准化生产——在GB200这样的高度定制化、出厂即一体的系统中,其重要性正在下降。

然而,危机之中蕴藏着新的战略机遇:

· 价值上移:竞争焦点从服务器内部设计,转向机柜级的液冷散热、供电效率与结构布局。

· 价值外延:核心竞争力从硬件制造,延伸至大规模部署的专业服务、跨平台运维管理以及与企业IT环境的整合能力。

这意味着,服务器厂商的角色正从一个标准产品的“定义者”,转型为复杂系统的“高级集成与赋能者”。

云厂商的“战略性采购”:在依赖与自主间寻求平衡

对于超大规模云厂商(Hyperscaler)而言,GB200既是战略必需品,也是战略警示。

· 短期战术:作为算力的终极标杆,采购GB200是满足市场对顶尖AI算力需求的必然选择。

· 长期战略:为防止供应链风险与技术锁定,自研AI芯片(如TPU, Trainium, Inferentia)已成为关乎未来自主权的核心战略。

云厂商的行为,生动体现了在效率与自主、短期市场与长期控制之间的复杂权衡。

终端用户的决策演变:从评估“组件”到考量“产出”

对于最终用户的技术决策者(CTO、技术VP)而言,采购的评估范式正在发生根本转变。

传统的采购清单:

· CPU的核心数与主频

· GPU的型号与数量

· 内存与存储的容量和速率

如今的战略考量:

· 效率指标:每瓦特性能、模型训练总时长

· 总体拥有成本:包含硬件、能耗、运维与人力在内的综合成本

· 业务敏捷度:从部署到产出的时间周期

这种转变,标志着企业技术采购从成本中心思维,向生产力投资思维的关键演进。

GB200重新定义了计算单元——从“服务器”到“机柜”。这不仅是性能升级,更是架构范式的彻底转变。效率的追求超越了组件堆砌,行业价值链正在重构。在这场变革中,唯一确定的是:适应它,或是被它抛下。

新的计算纪元已经开启。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

当您的设备拥有多个核心发热点,且它们彼此独立、功耗各异或需隔离冷却时,此时再用传统的单流道液冷板便力不从心了,而多回路型嵌铜管水冷板正是您破局的关键。

1-为何选择多回路?三大场景直击痛点

a.隔离热干扰,保障核心单元性能

当IGBT与二极管、CPU与GPU等不同器件密集排布时,单一流道会导致热量相互“串扰”,使低温器件被迫在高温下运行。多回路设计如同为每个器件配备了“专属空调”,彻底杜绝热干扰,确保每个单元均在最佳温度区间工作,从而提升整体系统性能与稳定性。

b.实现系统冗余,打造高可靠性架构

在对可靠性要求极高的领域(如服务器、通信基站),单一冷却回路的失效意味着系统宕机。多回路设计可构建 “N+1”冗余冷却系统。当一条回路意外失效时,其余回路仍能提供基础散热能力,为系统维护争取宝贵时间,是实现高可用性设计的基石。

c.应对异形布局与差异化散热需求

面对不规则排布的热源,单一流道难以实现均匀散热。多回路支持 “量体裁衣” ,您可以根据热源的实际形状和布局,灵活定制每一根铜管的走向,用最优的流道路径精准覆盖每一个发热点。同时,可为高功耗器件配置大流量回路,为低功耗器件配置小流量回路,实现散热资源的最优分配。

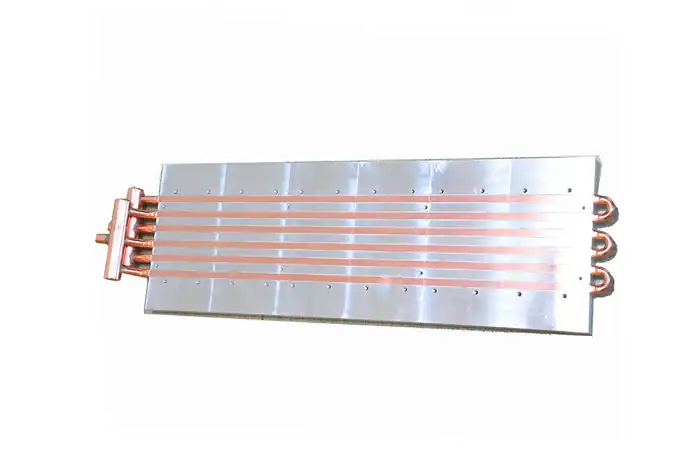

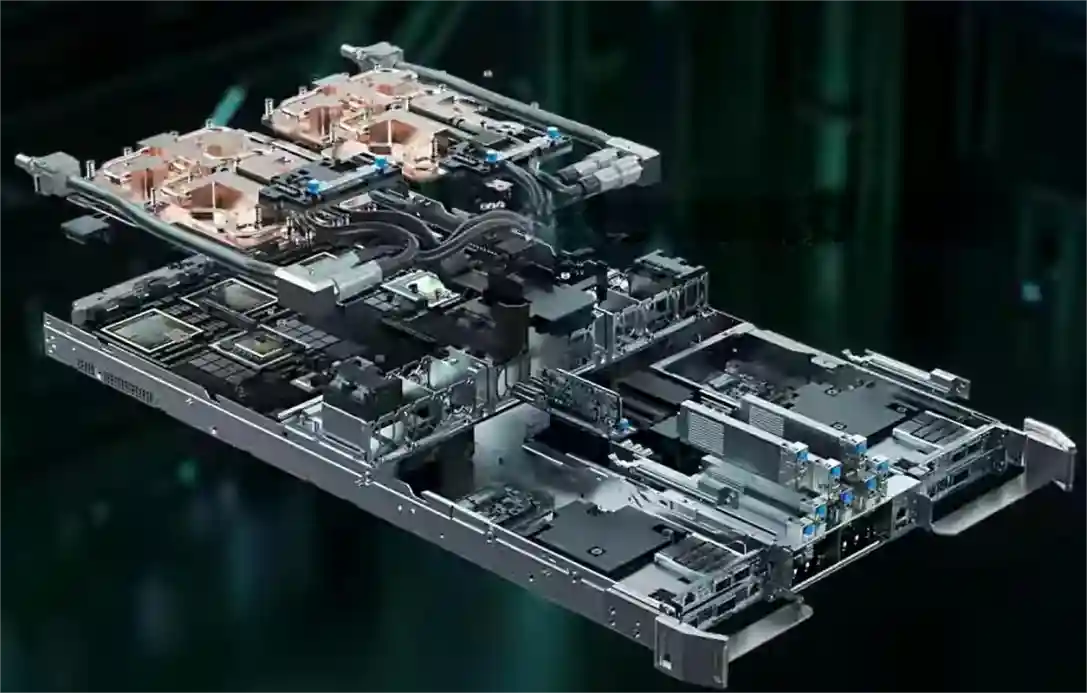

图1:多回路嵌铜管液冷板

2-设计与制造的核心:如何在方寸之间平衡性能与可靠?

在多回路设计中,流道间距是决定成败的关键。

a.热学底线:防止“热短路”

相邻流道间距若过小,即使流道独立,热量也会通过中间的铝基板快速传导,使隔离效果大打折扣。我们通过仿真与测试,确立了 ≥1.5倍管径 的基础间距原则,确保热独立性。

b.结构红线:守住“承压生命线”

流道间的铝基板是承受内压的薄弱环节。间距过窄会导致肋板强度不足,在压力冲击下有撕裂风险。我们通过机械应力仿真,确保在任何工况下,流道间的应力都远低于材料的屈服极限,从根本上杜绝“爆板”隐患。

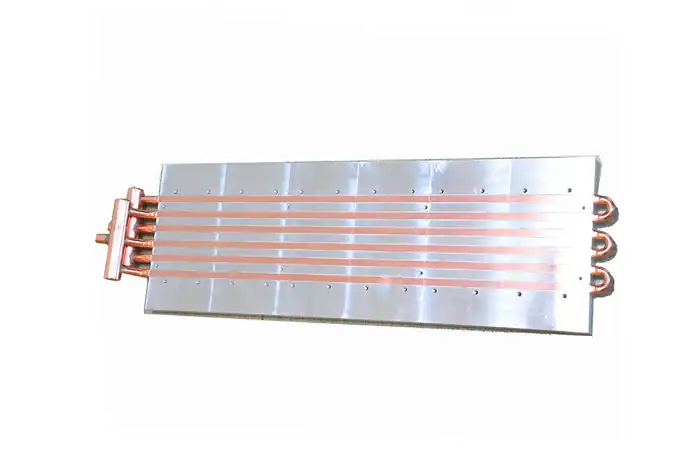

图2:嵌铜管液冷板

c.工艺极限:保障“精密制造”

狭窄的间距对铣槽刀具是巨大考验。我们基于丰富的制造经验,将间距与刀具直径关联,确保在高效加工的同时,获得光滑平整的槽壁,为后续铜管的紧密嵌套和低热阻结合奠定基础。

3- 工程实现要点

成功的多回路设计需要把握以下要点:

a.协同设计

建议在概念阶段就介入热设计和机械设计,综合考虑流道布局、结构强度和工艺能力,避免后续设计变更。

b.工艺控制

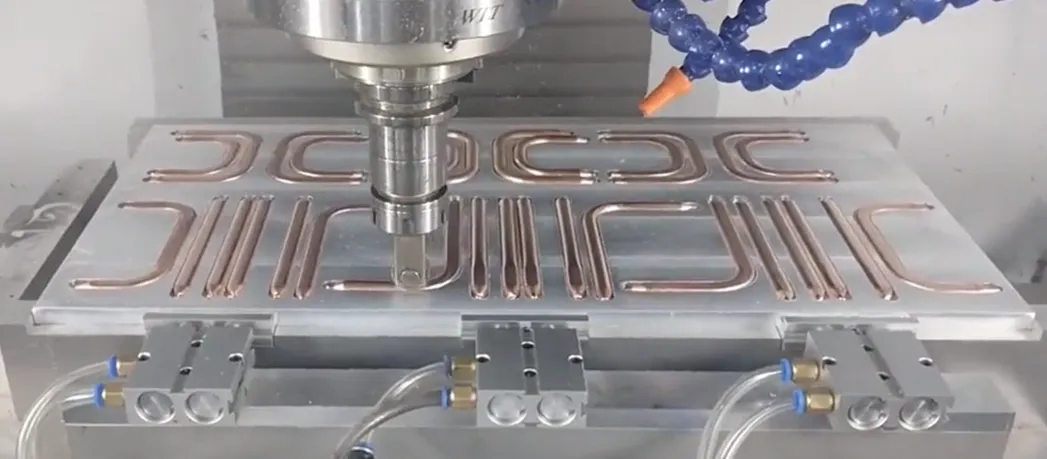

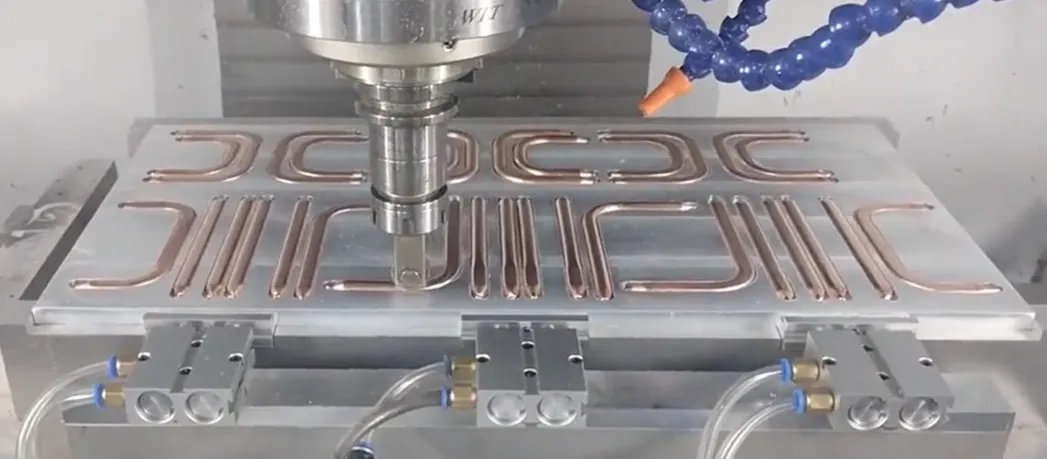

• 采用高精度CNC铣槽,确保槽宽公差与表面质量

• 使用带芯棒弯管技术,保证铜管弯曲后的通畅性与壁厚均匀性

• 可靠的嵌套固定工艺,防止铜管在振动工况下移位

验证测试

c.完善的测试体系包括:

• 100%气密性测试

• 流量-压降特性测试

• 热阻性能验证

• 爆破压力测试

总结而言, 多回路嵌铜管水冷板是解决复杂多热源散热问题的利器。成功的关键在于深刻理解其设计逻辑,并在性能与可靠性间找到最佳平衡点。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

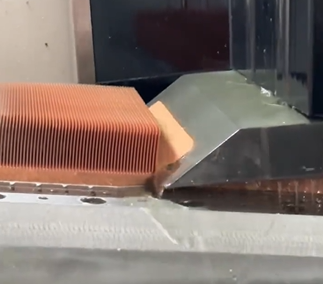

1-铜管预处理(折弯与压扁)

目标:将直的圆铜管,塑造成与设计流道完全一致的扁平形状。

a. 材料选择:为何是无氧铜?

无氧铜(C1220)纯度高达99.9%,无晶界氧化物,使其像面团一样延展性极佳,在折弯和压扁时不易开裂或产生微裂纹,保证后续可靠性。

b. 折弯半径:安全底线

最小弯曲半径 ≥ 1.5倍管径是铁律。小于此值,铜管外侧壁会被过度拉伸而减薄甚至破裂。使用芯棒弯管机是防止内侧起皱的关键。

c. 压扁:精密的“减肥”

压扁不是简单压扁,而是通过精密模具进行可控的塑性变形。压扁后的流道高度不得小于原始内径的30%。核心目标是保证压扁后壁厚均匀,不能出现局部死褶或过度减薄,否则此处就是未来的泄漏点。

图一:热管弯折

d. 工序抉择:先折弯还是先压扁?

必须“先折弯,后压扁”。对圆管进行弯曲是成熟可控的工艺;若先压扁,扁管几乎无法进行小半径高质量弯曲,且流道内壁会严重变形,流阻激增。

2-基板加工(精密铣槽)

目标:在铝基板上加工出用于嵌套铜管的、尺寸精确的“轨道”。

图二:嵌入式铜管

a. 槽宽设计:过盈配合

槽宽必须设计得略小于压扁铜管的宽度(通常小0.05-0.1mm),形成 “过盈配合” 。这能靠摩擦力紧紧“抱住”铜管,是实现初步固定和降低接触热阻的基础。

b. 槽深控制:飞切余量

槽深决定了铜管嵌入后凸出基板表面的高度,这个高度就是后续飞切工艺的加工余量。槽深一致性直接影响最终铜管剩余壁厚的均匀性。

c. 刀具与“刀颤”

加工窄而深的槽时,铣刀长径比过大易发生“颤振”,导致槽壁粗糙、尺寸超差。因此,流道间距不能过小,必须给刀具强度和刚度留出空间。

d. 清洁度:隐形的质量

铣槽后,铝屑和油污必须100%清除。任何残留物都会在铜管和铝基板之间形成隔热层,大幅增加接触热阻,使散热性能大幅下降。

3-嵌套与固定

目标:将成型铜管精准嵌入基板凹槽,并形成稳固的结合。

a. 过盈配合:主固定力

依靠精确的尺寸设计,通过压机外力将铜管“挤”进稍窄的槽中。材料自身的弹性回复力会产生巨大的正压力,这是最主要的固定力来源。

图三:热管固定

b. 辅助固定:防“跷跷板”

仅靠过盈配合,铜管端头在热应力下可能翘起。需辅助固定:微点焊(强度高,需控热)或高导热环氧树脂(应力小,有老化风险)。

c. 界面热阻的敌人

铜管与铝槽之间的空气是热的不良导体,是界面热阻的主要来源。高导热胶或焊接能填充微观空隙,取代空气,显著降低热阻。

d. 电化学腐蚀预警

铝和铜在电解质中会形成原电池,铝作为阳极会被腐蚀。必须确保冷却系统的密封性和使用去离子水/防腐冷却液,从系统层面切断腐蚀路径。

4-表面成型(飞切 vs. 深埋)

目标:形成最终可用于安装芯片的、具有高平面度和低热阻的散热表面。

a. 飞切工艺:性能王者

使用超硬刀具同时切削铜和铝,形成共面齐平的完美表面。这使得热源能与导热性极佳的铜管直接、大面积接触,实现最低热阻。

b. 深埋管工艺:可靠卫士

将圆铜管嵌入并填充高导热环氧树脂。铜管保持圆形,承压能力更强,填料提供了额外的保护和应力缓冲,可靠性更高,但热阻稍大于飞切。

c. 最终壁厚:生命线

飞切工艺的核心控制目标是铜管的最终剩余壁厚。它必须在性能(薄) 和可靠性/防切穿(厚) 之间取得平衡,通常控制在 0.15-0.3mm 的黄金区间。

d. 平面度:接触的保障

无论哪种工艺,安装面的平面度(通常要求<0.1mm) 都是硬性指标。微米级的起伏都需用导热硅脂填充,平面度差会导致接触热阻飙升,散热失败。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

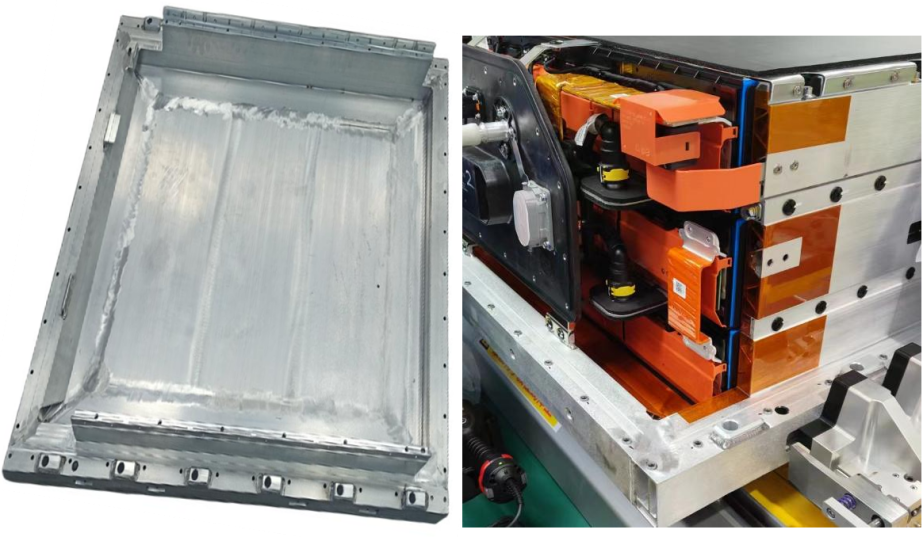

为提升电动汽车续航与容量,动力电池包正从单层布局转向多层堆叠结构。这一转变显著提高了能量密度,也带来了全新的结构挑战。本文将从核心难题、主流方案和未来技术方向三个方面展开探讨。

1-核心挑战:多层堆叠的力学难题

将动力电池包从单层扩展至多层,远非简单叠加。它重塑了内部的力学环境和外部的载荷路径,带来四大核心挑战:

a.垂直方向载荷激增与材料蠕变风险

·多层结构中,电芯、模组及结构件的重量会逐层累积。底层承受的静态压缩载荷远高于顶层。

·这种持续高压应力对材料的长期性能构成严峻考验,特别是抗蠕变性能(材料在恒定应力下随时间的缓慢塑性变形)。

·若层间支撑或电芯固定部件发生蠕变,会导致预紧力松弛,影响电芯循环寿命和界面接触稳定性。因此,寻找兼具轻量化和优异抗蠕变特性的材料至关重要。

b.膨胀力叠加效应与结构稳定性

·锂离子电池在充放电时,因电极材料体积变化会产生“呼吸效应”,导致电芯膨胀。在多层堆叠结构中,膨胀力逐层累积,使底层模组承受巨大压力。

·这种周期性应力易引发箱体鼓胀变形、密封失效、结构件挤压电芯导致短路,以及加速电池性能衰减。有效控制需依靠内置传感器实时监测结合数字仿真,从而指导结构优化设计。

c.空间利用与能量密度的核心矛盾

·应对重力和膨胀力需要加强结构(如增加横梁、加厚板材),但这会占用宝贵空间并增加重量,与提升体积能量密度和重量能量密度的核心目标冲突。

·解决之道在于结构优化和高效材料应用,这推动了电池包向多材料混合设计的转变。

d.碰撞载荷传递路径与安全冗余升级

·动力电池包高度增加,加剧了侧碰或底碰时的力学负荷;其增高结构放大了杠杆效应,对连接点强度和电池包自身刚度提出了更高要求。

·需采用抗冲击材料与一体化设计以优化传力与吸能,保障极端工况下电芯安全,进而推动电池-车身一体化(CTC)技术发展,使电池包成为车身结构的重要组成部分。

2- 主流结构方案对比分析

为应对挑战,业界探索了多种创新方案:

a.一体式压铸托盘(One-piece Die-cast Tray)

·优势: 集成度高,减少零件数量,提升整体刚度、一致性和密封性。工艺支持复杂几何形状,便于集成冷却、加强筋和安装点。整体结构利于管理复杂应力。

·挑战: 整体压铸多层框架对设备、模具和工艺要求极高,成本昂贵。碰撞后修复困难或不可行。整体刚性结构可能缺乏管理层间差异膨胀力的灵活性。

b.多级框架模块化(Multi-level Frame Modular)

·优势: 设计制造灵活,便于生产、维护和更换。天然适合多材料混合设计,可针对不同层级优化性能和成本。借鉴复合材料“准各向同性叠层”理念优化整体力学响应,分散应力。

·挑战: 零部件和连接件多,装配复杂,累积公差影响精度和预紧力。大量连接界面(螺栓、铆钉)是潜在失效点并增加重量。

c.混合材料夹层结构(Hybrid Material Sandwich Structure)

·优势: 卓越的轻量化效率和极高的比刚度(高强度面板+轻质芯材如泡沫/蜂窝铝)。强大抗弯性能,芯材兼具隔热和吸能特性,提升热安全和碰撞安全。符合多功能集成趋势。

·挑战: 制造工艺复杂,成本高。面板与芯材的界面结合强度和长期耐久性是关键。芯材需具备优异的抗压蠕变性能。

d.仿生蜂窝结构

·优势: 理论上是实现极致轻量化、高刚度和抗压强度的理想仿生设计(模仿蜂巢六边形)。提供均匀支撑,冲击吸能能力强。

·挑战: 制造极其复杂且成本高,与冷却系统等集成难度大。目前更多处于前沿研究阶段,大规模商业化应用仍需时日。

3-关键技术突破方向

未来解决多层堆叠设计难题的关键突破在于:

a.轻量化与刚度平衡的材料与工艺革新

·材料: 持续优化CFRP、铝合金、镁合金;开发兼具低蠕变、高绝缘、良好导热、易加工的新型多功能聚合物及复合材料。

·工艺: 发展先进连接技术(电阻点焊、激光焊、超声波焊)实现可靠、轻量的多材料连接。

图1:电池托盘机器人激光焊

b. 膨胀力自适应管理

思路从“刚性对抗”转向“柔性适应”,创造动态响应系统,使电芯在生命周期内处于最佳应力环境。

c.层间连接与一体化革命

·连接技术: 由螺栓机械连接向结构胶粘接与先进焊接演进,以实现更均匀的应力分布、良好密封和抗疲劳性能。

·终极集成: CTC/CTB(Cell-to-Chassis/Body)是未来电池包一体化的重要方向。通过取消独立外壳,将电芯或模组直接集成于底盘,使多层堆叠本身成为车身结构件(如横梁或地板),从根本上解决空间限制,最大化电池结构功能。实现该技术需电池、结构、热管理和安全等多领域深度协同,是“结构即功能”理念的终极形态。

图2:动力电池包电池托盘

多层堆叠是提升电池能量密度的必然选择,却也带来了结构、膨胀力与安全的巨大挑战。破局之道在于材料创新、仿生结构优化和膨胀力智能管理。最终,电池包将与车身深度融合,成为一体化的“能源底盘”。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

电动重卡两大核心挑战:电池布局与电池堆叠技术深度解析

当一辆满载货物的电动重卡行驶在高速公路上,支撑它跨越数百公里的核心秘密,就隐藏在车辆的底盘与电池舱内。在重卡电动化浪潮席卷全球物流业的今天,电池系统的布局与堆叠技术已成为决定市场胜负的关键。

图1:电动重卡电池液冷方案

电池布局:三大方案如何重塑电动重卡形态?

a.背式布局:短途运输的敏捷之选

·场景适配: 港口、矿山、钢厂等封闭场景的短途运输

·核心优势: 极速换电能力(具体时间需实测验证),提升车辆出勤率

·性能局限: 电池容量受限(行业普遍<350kWh),高重心影响高速稳定性

·空间代价: 占用货舱或驾驶室空间,降低载货能力

b.底盘式布局:长途干线的续航王者

·电量突破: 电池容量可突破500kWh(如行业公开的513kWh方案)

·空间魔术: 底盘空间高效利用,避免货舱侵占

·安全加成: 超低重心设计提升高速稳定性

·技术门槛: 底盘一体化开发,防护与热管理要求更高

c.底侧边式布局:换电网络的效率引擎

·换电革命: 侧向换电提升操作效率

·空间平衡: 保留完整货舱,续航能力介于背式与底盘式之间

·安全攻坚: 需强化侧撞防护结构

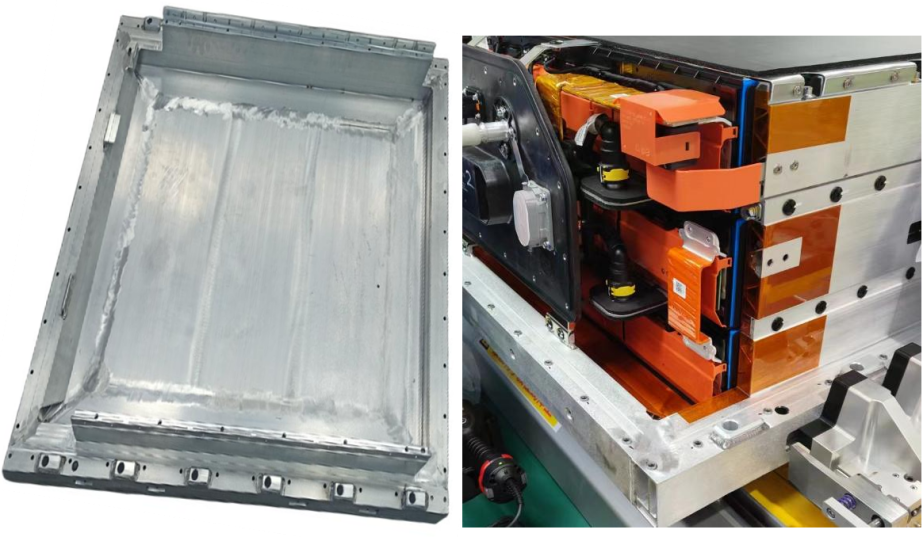

2-堆叠技术:重卡电池包的高效集成方案

多层堆叠技术正成为提升能量密度的关键路径:

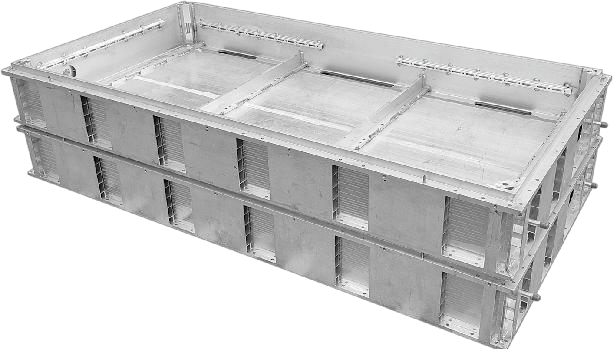

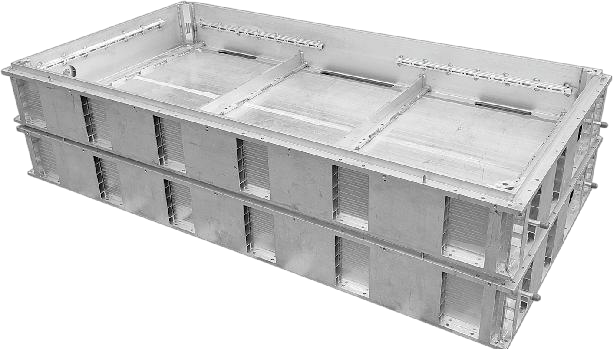

图2:堆叠式重卡液冷集成箱

a.无框架一体堆叠技术:

·电芯直接堆叠,减少结构件

·取消模组与框架,电芯直接“Z向无缝堆叠”

·显著提升系统能量密度

·支持超快充技术(具体性能需实测验证)

b.模组到底盘集成(如MTB/CTC技术)

·MTB技术:模组直连车架,体积利用率显著提升

·麒麟电池(CTP 3.0):72%体积利用率,255Wh/kg能量密度

·CTC技术:电芯融入底盘结构,减重10%

c.电芯形态创新(如刀片电池)

·扁平电芯紧密排列,体积利用率提升(比亚迪公开数据>50%)

·突破磷酸铁锂能量密度瓶颈

3-电动重卡的核心技术挑战

挑战1:结构安全

·极端工况: 侧柱碰撞对侧边布局构成致命威胁

·创新方案:高强铝合金壳体+缓冲结构;碰撞仿真优化(FEA);超国标机械冲击测试。

挑战2:热管理

·热失控警报: 包内温差控制至关重要

·技术突破:液冷板侧向冷却(温差<3℃);冷媒直冷技术;模型预测控制(MPC)动态调控。

挑战3:振动疲劳

·隐藏杀手: 道路振动导致结构损伤

·应对策略:Z向堆叠优化应力分布;路谱振动台架测试;高阻尼材料应用。

4-三大趋势引领当下发展

·底盘式布局主导中长途干线:高续航(>500kWh)与低重心特性成为首选

·CTC技术深度集成:电池与底盘结构融合,提升空间利用率和系统刚性

·智能化热管理普及:AI算法实现精准温控(温差<5℃),延长电池寿命

·固态电池技术演进:半固态电池加速商业化,潜力集中在安全性与能量密度提升

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

电动重卡的浪潮正席卷全球物流运输业,为“双碳”目标注入强劲动力。然而,伴随续航里程需求飙升而来的,是单包容量普遍突破500kWh甚至迈向1000kWh的超大电池系统。这如同在车上装载了一个移动的“能量堡垒”,其潜在的热安全风险也达到了前所未有的量级。当“超大容量”、“极速热蔓延”(<2分钟)、“超高抗撞”(>1500kJ)三大极端安全指标叠加,行业面临严峻的技术鸿沟。本文剖析这些挑战,并探讨构建电动重卡专属安全防线的系统化解决方案。

图1:短刀三层堆叠方案

1-500kWh+时代:机遇与安全挑战并存

a.容量跃升已成主流,为满足重载长途需求,电动重卡电池包已从200-300kWh快速跃升至600kWh+。巨头纷纷推出500kWh、600kWh乃至1000kWh级别的解决方案,标志着超大容量时代正式到来。

b.LFP(磷酸铁锂)电池技术的成熟是重要推手,其在安全性和循环寿命上的优势使其成为重卡主流选择。

2-极致安全下的“三大挑战”

a.热蔓延极限控制(<2分钟):

·核心目标: 安全设计必须延迟或阻断热蔓延,为人员逃生和救援创造时间窗口(如国标GB 38031-2020要求的5分钟预警)。

·严峻现实: 500kWh+高密度电池包内,单个电芯热失控释放的巨大能量极易引发灾难性链式反应。实测数据显示热蔓延速度极快:有案例22秒席卷全舱,5秒引燃相邻模组,模组间传播最短仅约44秒。

·核心难点与缺口: 如何有效确保模组间热蔓延被控制在2分钟以上? 目前尚无商用重卡系统公开承诺并验证能满足此严苛指标。

b.结构抗撞高墙(>1500kJ):

·核心需求: 满载重卡碰撞能量远超乘用车,轻松大于1500kJ,作为底盘结构件的电池包必须具备超高强度,碰撞后保持完整,防止内部电芯损伤引发热失控。

·严峻现实: 现行国内外标准(如GB/T 31467.3-2015, UNECE R100)对重卡电池包的碰撞能量测试阈值定义不清或偏低。公开的、通过1500kJ级别碰撞测试的认证数据极其缺乏。虽有更高能量仿真研究(如2500kJ),但完整系统验证仍是巨大挑战。

·核心难点与缺口: 缺乏明确的高能量碰撞防护标准及经过充分验证的解决方案。

c.二次灾害连锁风险(货物爆炸 & 道路瘫痪):

·货物爆炸风险: 电池热失控的高温火焰极易引燃货舱货物(尤其危化品),形成 “电池失控→货舱起火→货物爆炸”的灾难链。

·道路瘫痪风险: 锂电池火灾扑救困难(需大量持续冷却水)、易复燃。数十吨重卡在公路/隧道起火,救援复杂(高压断电、防毒气)、耗时长(可达数小时,影响或持续24小时),极易造成严重交通瘫痪,社会影响巨大。

·核心难点与缺口: 缺乏针对性的量化道路清障时效标准和高效应急处置体系。

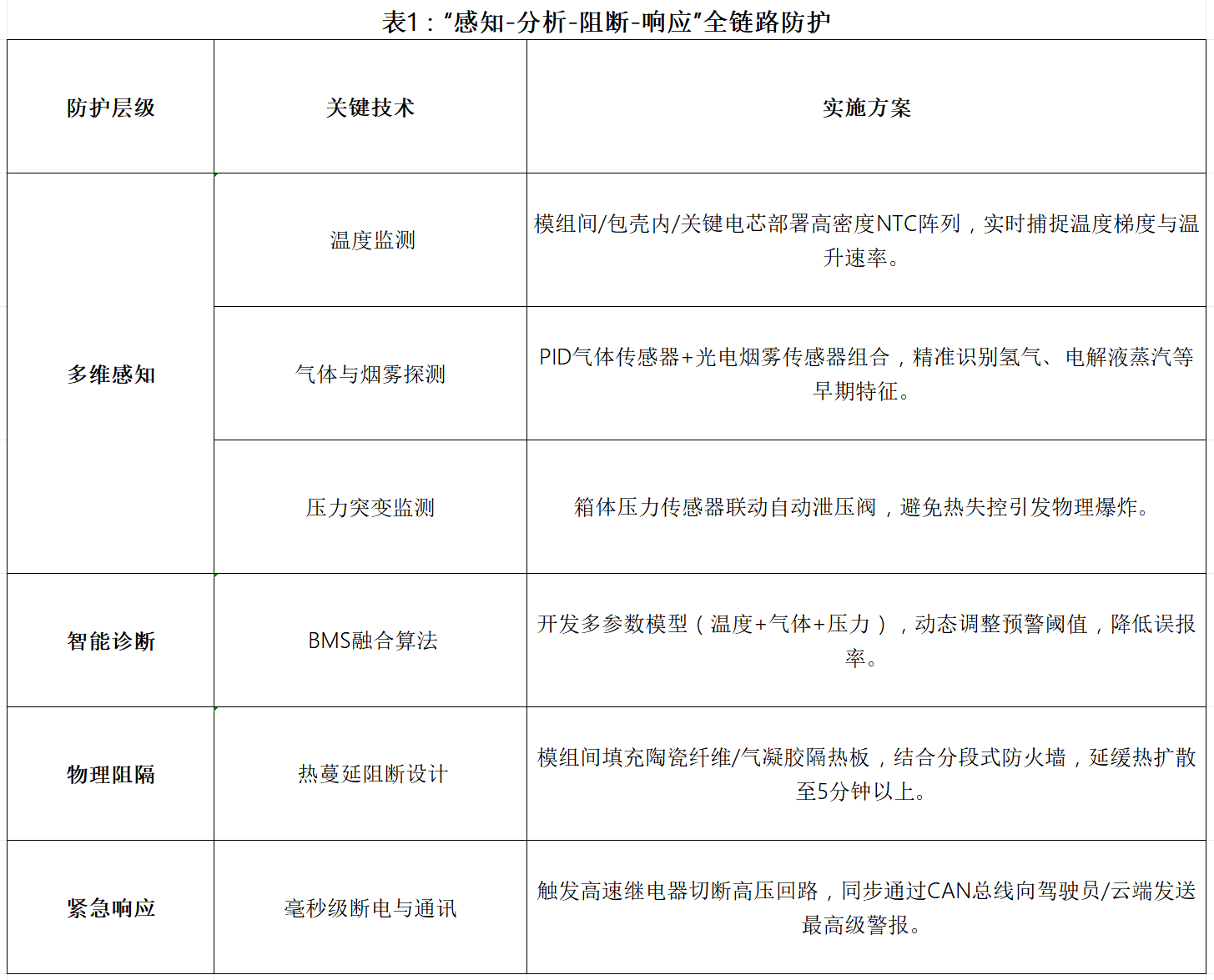

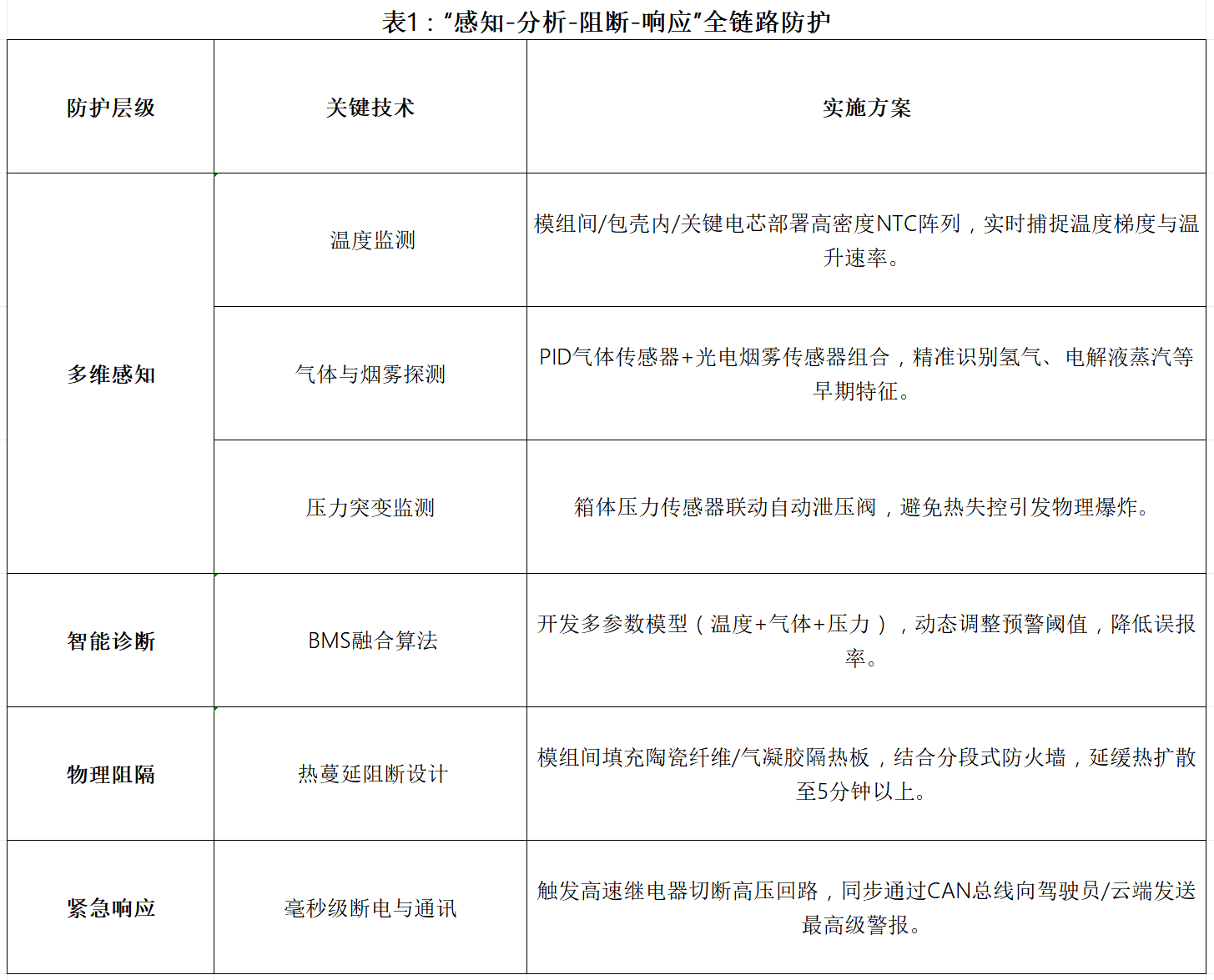

3-构筑防线:热事件预警系统设计:四重防护网

4-热管理配套方案:为预警系统赋能

液冷系统:集成高效液冷板,消除局部热点,维持电芯间温差<3℃。

模块化设计:独立可拆卸模组结构,支持故障单元快速更换。

智能监控平台:云端实时分析电池健康状态,预警信息自动推送至运维团队。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

在新能源重卡市场,“堆电量”正成为关键词:主流车型电池容量突破370kWh,600kWh以上车型密集亮相。这不仅是技术参数的跃升,更是行业对干线物流市场的攻坚宣言——通过提升单次续航能力,解决用户核心痛点“里程焦虑”,并优化全生命周期成本(TCO)。本文将拆解背后的商业逻辑与技术破局路径。

1-商业逻辑:为什么必须“堆电量”?

a.场景驱动的刚需

·封闭场景(短途高频):港口、矿山等场景依赖换电模式(3-5分钟补能),280kWh电池可满足需求。

·干线物流(长途运输):占货运总量70%,需单次续航500公里以上。600kWh+电池成为打开市场的“敲门砖”。

b.TCO的经济博弈

关键结论:日均行驶超300公里时,换电重卡TCO开始优于燃油车。

b.模式创新:化解成本之困

·电池租赁(BaaS):用户购“裸车”,电池月租(5000-9000元),初始成本降低30%。

·换电服务:度电服务费0.2-0.5元,综合能源成本约2.73元/公里(接近燃油车2.8元)。

·商业验证:换电站日服务50车次,投资回收期可缩至5年(IRR达13.1%)。

2-技术破局:如何平衡续航与自重?

a.空间布局的妥协:底盘换空间

·为避免电池挤占货仓,行业正优化电池布局。例如,将电池集成在车辆底盘内(取代传统的背挂式),释放货箱空间、降低重心并可能改善能耗。

·代价: 这牺牲了部分离地间隙和底盘设计的通用性。

b材料科学的妥协:能量密度换重量

·减轻车重的根本在于提升电池能量密度(单位重量存储更多电量)。更高的能量密度能让电池更轻,或在相同重量下跑得更远。

·核心是电池材料创新(如高镍正极、硅碳负极)。

·代价: 能量密度的提升往往伴随安全性风险、寿命缩短、成本增加和快充能力下降等问题,需要在多个性能间艰难权衡。

c.商业模式的妥协:网络换单车压力

·新能源重卡换电模式巧妙地将无限续航的压力从单车转移到了换电网络上。通过在干线沿途密集设站,车辆只需携带足够到达下一站的电量,无需背负跑全程的巨大电池。

·效果: 这降低了对单车电池容量的极端要求,使电池装载量更趋“合理”。

d.残值管理:BaaS的核心壁垒

电池银行需构建全生命周期能力:健康度(SOH)监控、 梯次利用、 回收体系。

图1:重卡电池pack箱

3-未来趋势:从“堆电量”到“高效载电”

a.技术迭代:固态电池将突破能量密度瓶颈,重塑自重与续航平衡。

b.补能网络:重卡换电标准统一与电网协同(如调峰)是规模化关键。

c.多路线竞争:氢能重卡在长途重载领域仍具替代潜力。

阶段性策略,长期性进化:

“堆电量”是电动重卡攻坚干线物流的必然选择,其本质是商业场景需求与技术现实间的动态平衡。随着电池技术跃迁和商业模式成熟,行业将从“电量竞赛”转向“效率竞赛”。而当下,它正推动中国新能源重卡完成从“小众”到“主流”的关键一跃。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

重型卡车(重卡)作为公路物流的核心运力,其动力电池系统的安全性、可靠性与经济性成为技术焦点。电池托盘作为承载、保护和管理电池模组的关键结构件,正面临着前所未有的极限挑战。

图1:电动重卡电池托盘

1-重卡托盘的极限挑战

a.严苛的机械耐久性要求:振动、冲击与百万公里寿命

重卡设计寿命 ≥150 万公里,是乘用车的 10 倍以上。电池托盘必须在这一“全生命周期”内,持续承受以下三类极端机械载荷:

·高频随机振动:满载通过非铺装、施工或坑洼道路时,底盘会在 5 Hz–2 kHz 的宽频带内产生随机振动。这些振动不仅考验托盘主框架的疲劳极限,更在焊缝、螺栓孔、翻边等应力集中区诱发微裂纹,成为失效起点。

·高 g 瞬时冲击,路面深坑、紧急制动或装卸跌落可在毫秒级内产生 50 g 以上的冲击加速度。托盘需在瞬间吸收/分散能量,防止电芯发生位移、短路或壳体破裂。

·累积疲劳破坏,百万公里意味着上亿次振动循环。铝合金在交变应力下易产生疲劳裂纹并扩展,最终导致结构断裂。设计的核心任务是通过拓扑优化、局部加强、异种材料混合及工艺控制,将裂纹萌生寿命推迟至整车退役之后。

b.复杂的热管理与热循环挑战

重卡电池包因超大容量(数百kWh)与高功率充放电产生巨量热量,且运行环境横跨寒带至热带,面临极端温差。

·宽温域控制:托盘及热管理系统须在-40℃至+85℃ 环境温度下,将电芯温度精准维持在25-40℃最佳区间,且单体温差<5℃;

· 强应力循环:实验室加速老化测试中,需承受数千次 -40℃↔85℃ 剧烈温变循环(速率5-15℃/min,极值驻留5-15分钟)。此过程引发材料(铝合金/密封胶/塑料件)界面反复热胀冷缩,对集成冷却管路的焊接/胶接点可靠性构成严峻考验。

2-主流材料方案与多功能集成技术

为应对上述挑战,行业在材料选择和设计理念上形成了以高强铝合金为基础,向多功能高度集成演进的技术路线。

a.核心材料选择:6xxx系铝合金的统治地位

在与钢、镁合金及复合材料的竞争中,6xxx系(Al-Mg-Si)铝合金凭借其优异的综合性能、成熟的加工工艺和较高的性价比,已成为重卡电池托盘的“主流”材料。

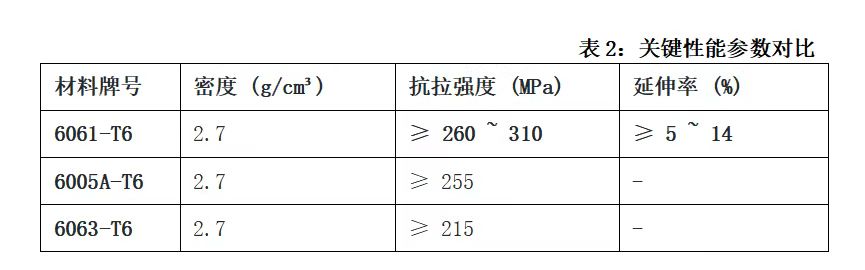

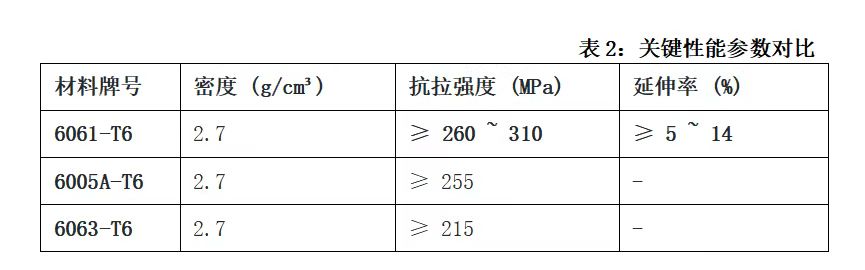

主要牌号及性能:

· 6061-T6:这是应用最广泛的牌号,以其卓越的强度、良好的可焊性和抗腐蚀性著称。

· 6005A-T6 和 6063-T6:作为补充选择,同样具备良好的挤出性能,适用于对强度要求稍低的部件。

b.设计理念转型:热管理与结构健康监测

现代重卡电池托盘的设计理念已发生根本性转变,不再局限于提供物理支撑的“承载体”,而是进化为高度集成的“智能温控平台”。这一趋势主要体现在两大技术方向上:

· 高效热管理集成(成熟应用),这是目前技术最成熟、应用最广泛的集成领域。核心思路是将冷却功能直接融入托盘的结构设计中,实现高效且紧凑的热管理。

· 结构健康监测(SHM)的探索(早期阶段),该技术的目标是预警托盘在长期使用中可能出现的结构损伤(如裂纹、变形)。尚处验证和实验室研究阶段,尚缺乏大规模商业化部署的案例以及长期运行可靠性的充分数据支持。

3-核心制造工艺路线分析

重卡电池托盘的制造工艺,直接决定了其成本、性能和生产效率。目前主流路线以铝型材挤压和摩擦搅拌焊(FSW)为核心组合,可完美适配重卡托盘性能需求与当前中小批量生产模式。

a.铝挤成型:该工艺通过模具挤压铝锭形成长条形构件(横梁/纵梁等),是重卡电池托盘核心制造技术。优势在于模具成本低、开发周期短,尤其适应大尺寸非标件的小批量生产。但需经切割、加工及多道焊接组装,工序繁杂导致自动化程度低、生产节拍慢,效率逊于一体化压铸工艺。

b.搅拌摩擦焊(FSW):作为固相连接技术,FSW通过旋转搅拌头摩擦生热实现铝合金高强度焊接,成为托盘高承载/密封接头的首选。焊缝强度达母材80%-90%,无气孔裂纹缺陷,热变形小保障IP67+级密封且绿色环保。局限在于仅适用于平面/简单曲面焊接。

铝合金重卡电池托盘已从高强轻量化结构跃升为多功能集成平台,但激增的功能引发多场耦合失效、工艺复杂度及可靠性挑战。未来突破需依靠材料-工艺-系统协同创新,通过自适应界面与数字孪生技术,实现智能托盘的安全可持续演进。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

降本驱动的大电芯革命与冷却挑战:储能行业正经历一场由“降本增效”驱动的深刻变革——大电芯技术路线迅速崛起。300Ah+电芯渐成标配,500Ah乃至更大容量电芯加速落地。这场变革在提升系统能量密度、降低单瓦时成本的同时,也带来了严峻挑战:单个电芯质量激增,模组/PACK整体重量飙升,对底部支撑结构的承载压力成倍放大;更大的发热功率、更长的内部热传递路径,对散热系统的效率和均匀性提出极限要求。作为PACK热管理核心的液冷板,首当其冲面临升级压力。

传统的“薄板覆盖式”液冷板设计已难以为继。在有限的空间约束和严苛的成本控制下,液冷板必须突破单一散热功能,向“结构功能一体化、散热极致高效化、系统轻量化” 三位一体的方向演进。本文将深入拆解这一进阶设计路径。

1-结构功能集成化:液冷板的“承重革命”

当电芯质量大幅增加,箱体底板及液冷板承受的载荷剧增。将液冷板设计为承载结构件,是解决重量、成本、空间矛盾的关键突破点。

a.成为箱体“骨骼”:一体化承重底板

·设计理念: 液冷板不再依附于箱体底板,而是直接成为箱体主承重结构。

·核心优势: 大幅减少传统底板和安装支架,显著降低系统重量和材料成本,简化装配流程。

·技术要求: 必须具备极高的抗弯、抗压、抗冲击刚度和强度

b.内嵌“钢筋铁骨”:拓扑优化与加强结构

·力学主导设计: 利用CAE仿真进行拓扑优化,在冷板非关键散热区域(如流道间隙、边缘)集成加强筋等。

·材料高效利用: 优化设计确保材料分布在应力关键路径,移除冗余材料,在保证承载能力的同时实现轻量化。

c.模组级承载平台:化零为整

大尺寸、高强度的液冷板可直接作为模组的安装基板和承载骨架。电芯或模组直接固定其上,省去额外支撑框架,进一步精简结构,提升体积利用率。

2-散热性能跃升:高效与均匀的平衡艺术

大电芯的核心痛点在于中心区域散热难、整体温差控制难。液冷板设计需从流道、界面、材料多维度创新。

a.流道设计:从“简单管道”到“智能血管”

·精准分流与强化扰流: 采用树状分支流道、蛇形+扰流柱/翅片复合结构,针对电芯中心高热区增加流量和扰动。避免大通径直道造成的“边缘冷却快,中心冷却慢”。

·变截面与分区冷却: 根据电芯不同区域发热量(如中心>边缘),设计渐变截面流道或独立可控的分区回路,实现热量的精准按需分配,温差控制可达±2℃以内。

·仿生与拓扑优化流道: 应用CFD和拓扑优化技术,生成高效低阻的“自然生长式”流道网络,最大化换热面积与效率,降低泵功损耗。

b.突破界面热阻:让“接触”更紧密

·高性能界面材料(TIM): 研发高导热(>5W/mK)、低热阻、长期稳定的导热垫片/凝胶/相变材料,并兼顾绝缘、缓冲和工艺性。

·微结构表面工程: 在冷板接触面加工微沟槽、阵列微凸点或应用特殊涂层,增大有效接触面积,利用毛细力增强接触,显著降低界面热阻(可降30%-50%)。

c.材料升级:导热与强度的双重追求

在保证结构强度的前提下,探索更高导热系数的铝合金(如高导热6系、特定7系合金)或铝基复合材料(AMCs),提升基础导热性能。

3-轻量化贯穿始终:克克必争的重量博弈

每一克的减重都意味着成本降低和运输安装效率提升。

精细化的“瘦身”设计:

a.仿真驱动减薄: 通过CAE精确计算,在满足强度、刚度、散热要求下,最大化减薄冷板壁厚(如从2.0mm减至1.5mm)。

b.中空结构与镂空: 在加强筋内部、非关键区域设计中空腔体或进行安全镂空处理。

c.高强度材料应用: 采用更高强度的铝合金(如7xxx系),实现同等性能下的厚度减薄和重量降低。

4-制造工艺:支撑进阶设计的基石

液冷板的“结构化”和“复杂化”对制造工艺提出更高要求。

主流工艺的升级与融合:

·铝挤+搅拌摩擦焊(FSW): 优势在大尺寸、高结构强度。进阶方向:开发集成流道与加强筋的复杂型材截面;突破超长、变截面FSW焊接技术,保证焊缝强度和气密性。

·冲压+钎焊: 优势在流道设计灵活、轻量化潜力大。进阶方向:实现更深、更复杂流道的精密冲压;提升大尺寸、多零件钎焊的良率和接头可靠性;在冲压件上集成加强结构。

·高压压铸: 潜力在制造高度集成(流道、筋位、接口一体)、形状极其复杂的冷板。需攻克模具成本、内部流道表面光洁度、气孔控制等难题。

·混合工艺创新:多工艺组合创新,融合不同工艺优势,应对更复杂设计需求。

5-可靠性:集成设计的生命线

当液冷板成为结构核心,其可靠性关乎整个PACK的安全。

强化“结构-流体”双重可靠性:

a.极限机械验证: 需通过远超标准的振动、冲击、挤压、跌落测试,模拟极端工况。

b.疲劳寿命保障: 进行详尽的结构疲劳和压力循环仿真与测试,确保在长期交变载荷下无泄漏、无开裂。

c.冗余密封设计: 关键接口及采用多重密封策略。

d.严格的质量控制: 引入自动化在线检测,确保制造一致性。

储能液冷板的进阶之路,是技术创新驱动产业降本增效的生动缩影。谁能在“结构功能一体化”的设计竞赛中拔得头筹,谁就将在万亿储能市场的角逐中占据先机。这场静默的“底板革命”,正悄然重塑储能系统的未来形态。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

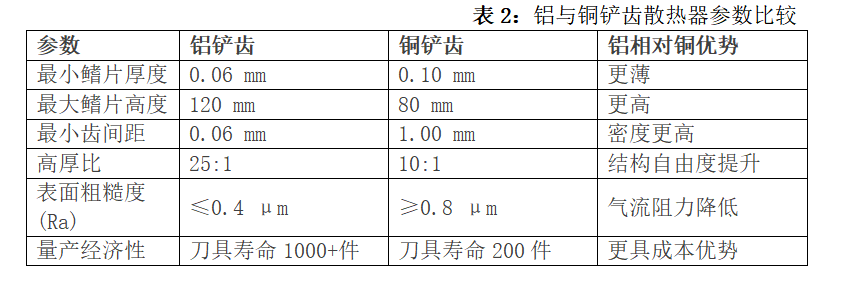

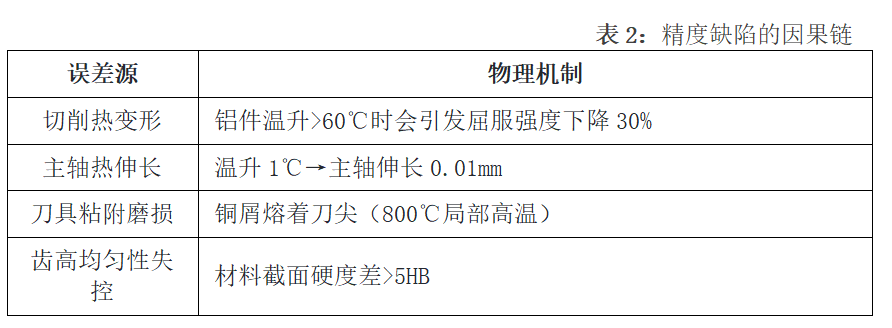

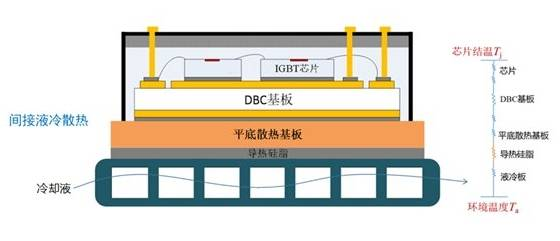

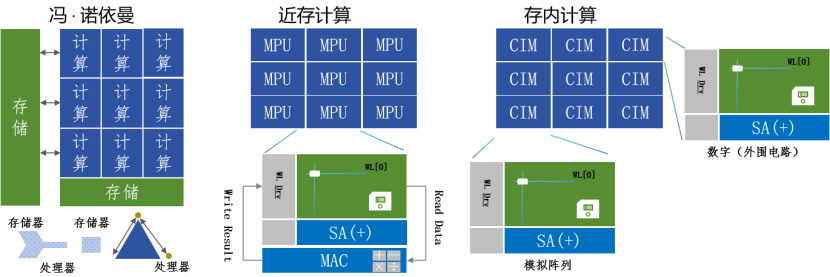

IGBT散热本质是多层热阻串联下的热量输运效率问题,其中界面热阻占比超60%,是主要优化对象。

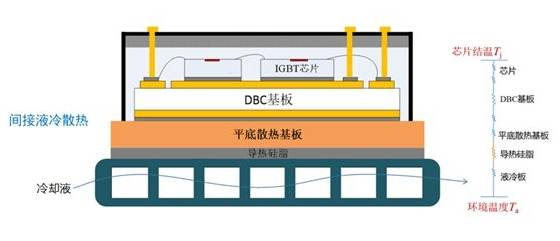

图1:IGBT热阻示意图

1-问题根源:热阻究竟藏在哪里?

IGBT模块的热阻构成是一个复杂的多层结构,涉及多个材料层和热传导路径。IGBT模块的热阻构成主要由IGBT模块的热阻(Rth )由结-壳热阻(Rth-Rjc )和壳-环境热阻( Rth-Rca)串联构成:

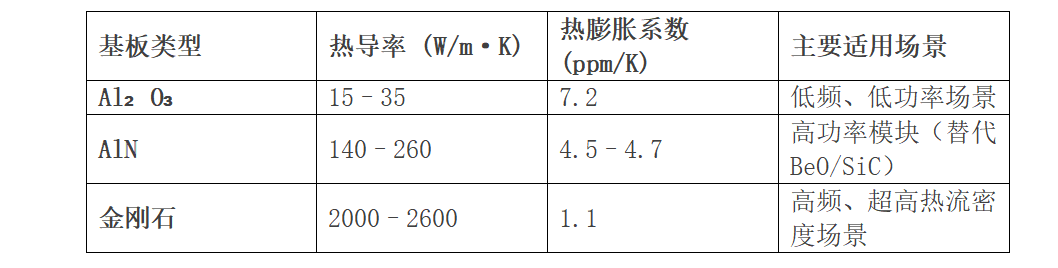

a.结-壳热阻(Rth-Rjc ):

· 覆铜陶瓷板是主要瓶颈:占的Rth-Rjc 75%以上,因其陶瓷层(如Al₂O₃)导热率低(15–35 W/m·K)且厚度不可忽略 。

· 其他层级占比:芯片热阻(硅基导热率≈150 W/m·K)、焊料层热阻(空洞导致界面热阻)、铜基板热阻(导热率高但厚度影响小)共同构成剩余25% 。

b.壳-环境热阻(Rth-Rca ):

· 界面接触热阻占主导:基板与散热器间的导热硅脂/接触面热阻占总热阻的40–60%,在单面散热传统设计中占比>60% 。

· 散热结构影响:如风冷散热器中,接触热阻(Rjc)、导热热阻(Rch)、换热热阻(Rha )分别占比65.9%、5.9%、28.2%(常规翅片结构)。

2-热阻攻克路径:材料与结构协同优化

a.芯片减薄:降低内部热阻

· 技术演进:从PT型晶圆200μm减薄至IGBT7的70μm,热阻降低60% 。减薄工艺(研磨/CMP/等离子刻蚀)可释放应力,提升热扩散效率 。

· 物理机制:厚度从350μm降至110μm,单位面积热容(Cth )从786.5 J/℃·m²降至247.2 J/℃·m²,加速瞬态散热 。减薄后电阻减小,欧姆接触增强,降低内应力导致的失效风险 。

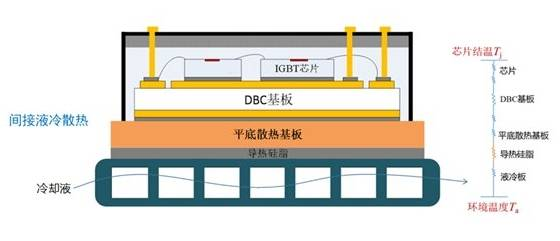

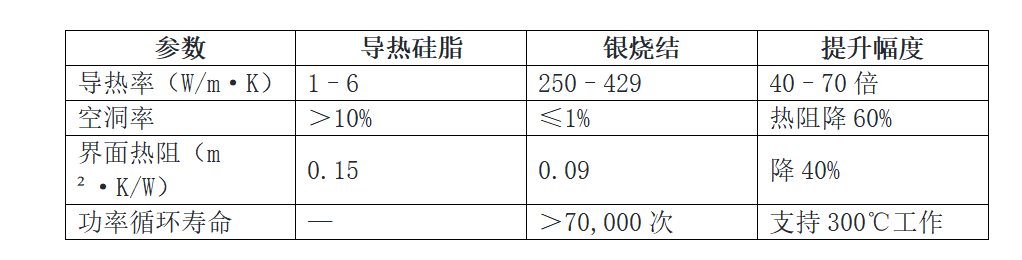

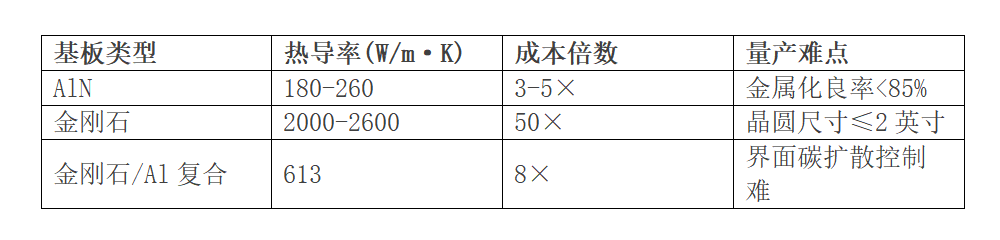

b.界面革新:银烧结替代导热硅脂

界面材料升级是降低接触热阻的核心:

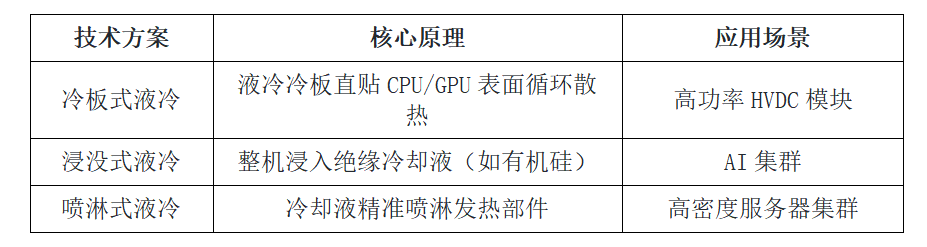

表1:银烧结与导热硅脂导热性能对比

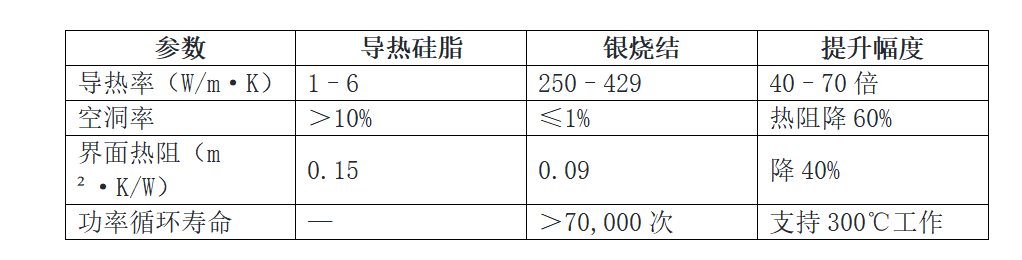

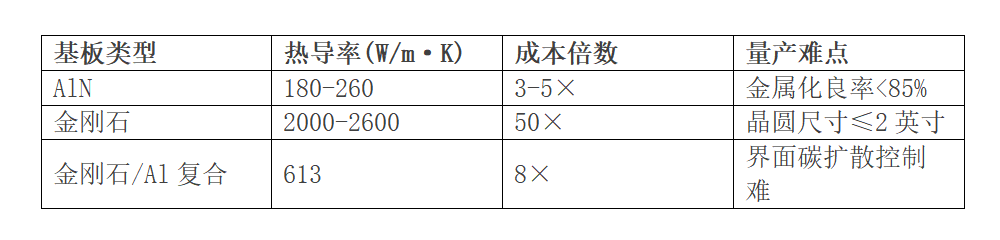

c.基板升级:高导热陶瓷与金刚石

基板材料正经历从 Al₂O₃ 到 AlN 再到金刚石的关键演进,核心目标是显著提升热导率,以满足更高功率密度电子器件的散热需求。

· AlN 基板的突破

热导率可达 Al₂O₃ 的 5–10 倍。热膨胀系数 (约 4.5 ppm/K) 更接近硅 (约 2.6 ppm/K),有效降低了与硅芯片间的热失配应力。

· 金刚石基板前景: 热导率超2000 W/(m·K)(Al₂O₃的80倍),热膨胀系数1.1 ppm/K,完美匹配硅芯片。金刚石/铝复合材料热导率达613 W/(m·K)(纯铝2.6倍),界面优化提升结合强度。

表2:关键基板材料性能对比

3-热阻攻克挑战

a.芯片减薄的机械强度瓶颈

厚度从200μm降至70μm(IGBT7)可降热阻60%,但继续减薄至20μm将引发断裂风险。超薄芯片(<50μm)因热膨胀系数(CTE)失配易产生微裂纹。

b.高导热基板挑战

表3:高导热基板挑战

c.界面可靠性:多物理场耦合挑战

·银烧结CTE失配风险:银烧结层(CTE=18.4 ppm/K)与SiC芯片(CTE=4.5 ppm/K)差异达4倍,热循环易分层。

·界面接触压力控制:压力0.1→0.5 MPa可降热阻40%,但>1 MPa会挤出银层。

当IGBT功率密度迈入10kW/cm²时代,散热设计已从「辅助工程」跃升为「系统瓶颈破局点」。从Al₂O₃到金刚石的基板革命、从硅脂到铜烧结的界面跃迁、从200μm到50μm的芯片瘦身,本质上是一场对抗热力学第二定律的攻坚战。散热设计逼近物理极限,材料-结构-工艺三角协同将成为破局关键。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

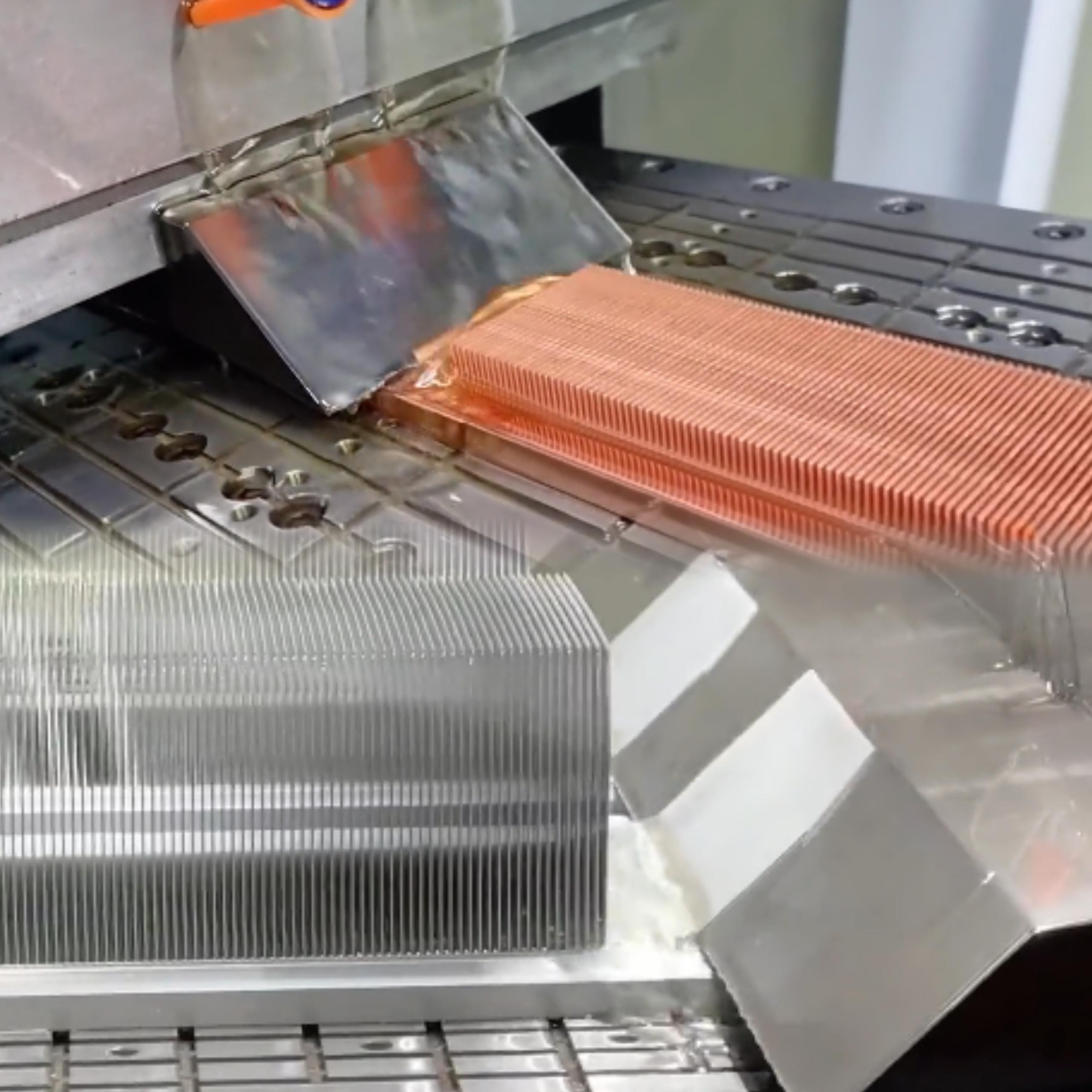

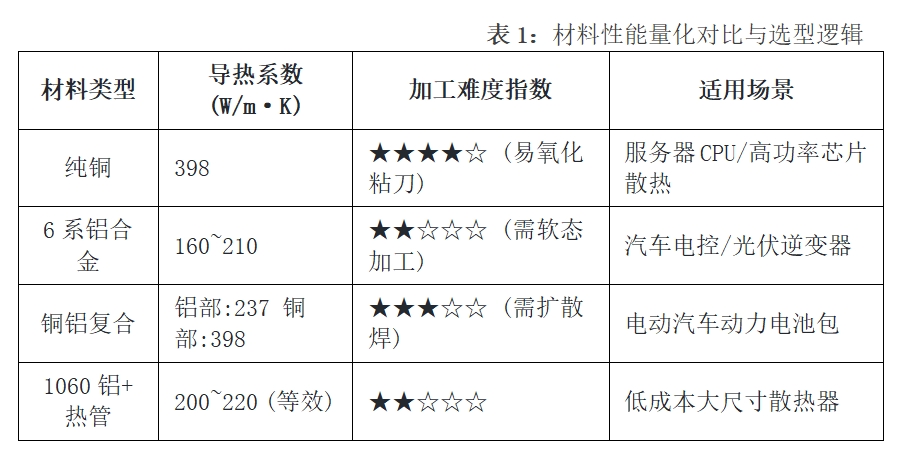

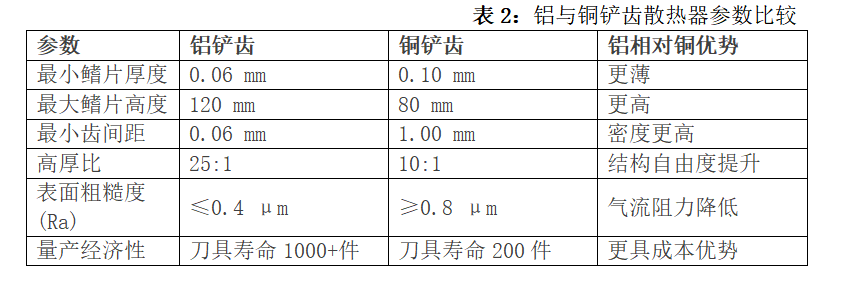

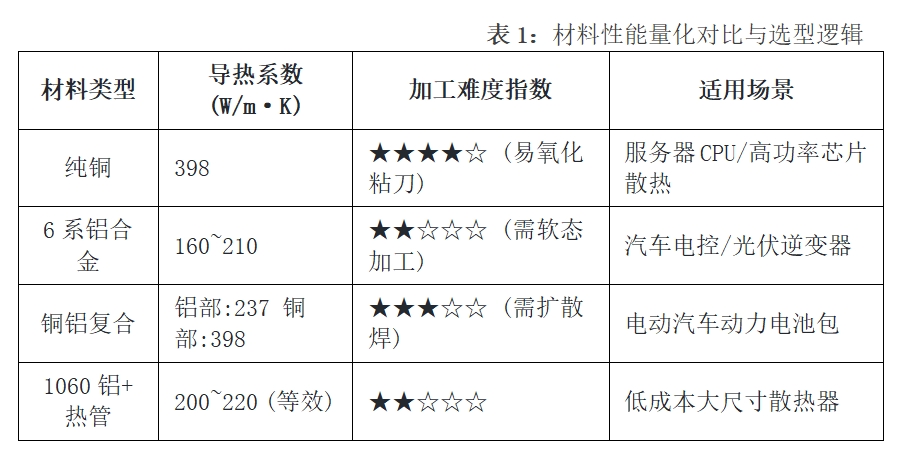

铝代铜在铲齿散热器领域已成不可逆趋势,核心驱动力是成本、轻量化与资源安全,并通过工艺创新(铲齿技术、微通道设计)弥补性能差距。典型应用中,数据中心、新能源汽车等高效能场景已广泛采用铝方案。然而,铝代铜并非简单材料替换,而是一项系统工程,需要从材料选型、结构设计、制造工艺到应用场景进行全面优化,才能实现成本与性能的最佳平衡。本文将深入探讨这一替代实践中的关键技术突破与应用方案。

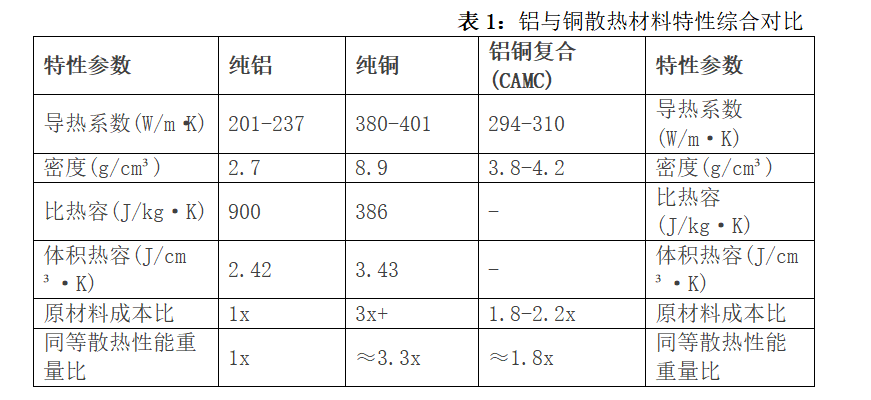

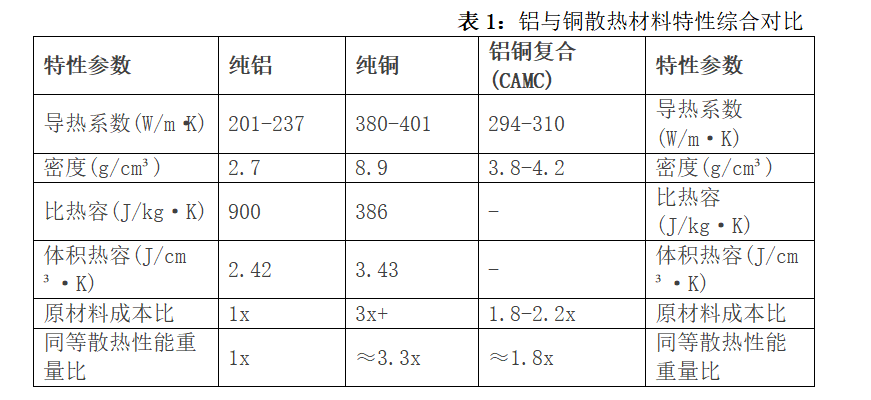

1-铝vs铜:材料特性与替代挑战

要科学评估铝材替代铜材的可行性,必须首先理解两种金属在散热应用中的核心物理特性差异:

散热器性能不仅取决于材料导热性,还受制于热容特性与表面积利用率。铝材与铜材的物理特性差异决定了替代的可行性边界:

a.导热与热容的辩证关系

·铜的瞬时优势,高导热系数(385W/m·K),初始热扩散更快;

·铝的稳态破局,高比热容(900J/kg·K,铜的2.3倍),单位质量储热能力提升133%,低密度(2.7g/cm³,铜的30%),同体积可增加40%散热面积,持续散热阶段通过更大表面积实现长效均衡。

b.热匹配性加成

铝热膨胀系数(23.1×10⁻⁶/K)接近PCB基材(13-18×10⁻⁶/K),减少热应力失效风险。

此外,性能观革新——接受局部导热系数下降,换取系统级轻量化、成本优化及可持续性提升,则推动了这一趋势扩散。

2-制造工艺的关键突破

a.材料体系突破:合金成分优化与硬度调控

·传统痛点:传统铝材(如1060纯铝)硬度低(24-38HB)易铲齿,但后续机加工易粘刀;6063铝合金硬度高(34-42HB)虽利于后期加工,但铲齿高度受限(≤50mm)。

·突破点:通过合金成分优化(Si 0.25%、Mg 0.41%)与熔铸工艺创新(556℃均匀化+430℃挤压/490℃淬火),实现铝材硬度分阶段调控:铲齿前保持32-39HB低硬度(保障70mm高齿加工),铲齿后时效强化至55-64HB(解决机加工粘刀问题)。

·杂质控制与导热性平衡:配合Fe≤0.11%、Cu≤0.02%的高纯度控制(99.70%铝基),在提升机加工效率的同时维持高导热性,使高齿铝散热器兼具加工性能与服役强度。

b.材料硬度与切削响应的本质差异:铝材实现超薄鳍片的核心优势在于其加工硬化特性与切削力需求。

技术解析:

·铜的软质特性导致铲齿过程中:刀具挤压易造成鳍片根部材料堆积(形成“卷边效应”)

薄片区域塑性变形严重(厚度<0.1mm时失稳率高);加工硬化程度弱,无法通过形变强化结构。

·铝合金在铲削时:加工硬化显著提升鳍片刚度(6063合金冷作硬化后强度提升);低切削力允许使用更精密的薄刃刀具;弹性恢复量小(约铜的1/3),确保鳍片几何精度。

c.结构极限突破与成本优化

超薄鳍片的设计本质是最大化表面积/体积比,铝材的物理特性更适配此目标:

采用简单截面铝型材(板型/槽型)替代复杂模具,模具成本降低60%。小批量生产直接使用板材铲齿(免模具),适配定制化需求。

3-趋势本质:系统优化替代材料本位主义

铝代铜铲齿散热器的核心价值在于系统层级的综合优化,而非单一导热性能的替代:

·技术杠杆:通过高倍齿结构、薄齿工艺及一体成型实现轻量化与高效散热的协同突破;

·轻量化集成优势:在新能源/5G等新兴领域,轻量化与成本成为比绝对导热率更关键的指标,衍生效益提升。

·全周期经济性:初期成本仅为铜方案的45%,叠加轻量化带来的风机功耗降低,实现快速的投资回收。

·可持续制造基础:铝材产能充足、回收率>95%的产业特性,为供应链稳定性提供保障。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

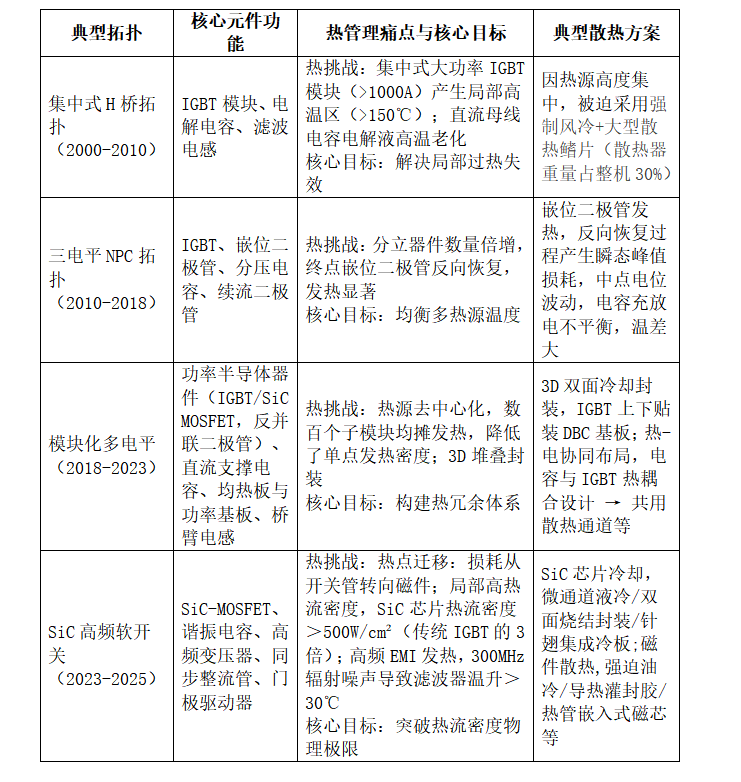

功率密度不断提升,而热边界却限制着它,这种相互较量促使光伏逆变器散热技术经历了四次重大变革。最初是集中式 H 桥采用翅片风冷这种方式苦苦应对散热问题;后来三电平 NPC 拓扑结构出现,利用热管来控制发热源;接着模块化多电平技术登场,用相变材料建立起热冗余防线;直到如今 SiC 软开关技术配合微通道液冷攻克了热流密度高的难题。每一次电路拓扑结构的更新换代,都在改写散热的模式。这整个进化过程,本质上是电力电子在效率、功率密度、可靠性这三个相互制约的因素下,对热力学第二定律极限的挑战,也将决定下一代光储融合系统竞争的门槛。

1-光伏逆变器系统演化

光伏逆变器系统演化遵循散热适配→热管理→热协同→熵减系统四阶跃迁,驱动形态从柜式集中走向芯片级智能集成,功率密度不断突破,效率与场景穿透力同步跃升。

a.光伏逆变器物理形态经历的三次升级:

早期集中式逆变器体积庞大(>1m³/MW),重量超吨;而后的组串式方案将功率单元拆解为20-100kW模块,体积缩至0.3m³/MW;当前模块化设计进一步推进至10kW级子单元,功率密度突破50kW/L,重量降至<15kg/kW。

b.环境适应性从被动防护转向主动适应:

·防护等级:IP54→IP66/C5-M防腐(沿海/盐雾场景)

·温度范围:-25~+60℃→-40~+85℃(极寒/沙漠场景)

·智能响应:动态温控算法实时调节散热功率,匹配粉尘/高湿环境

c.散热需求随功率密度跃升质变:

早期强制风冷应对<100W/cm²热流密度;三电平时代热管技术解决多热源均温;SiC高频化推动液冷普及;微通道相变冷却正成为>300W/cm²的标配方案,散热系统占比从整机30%压缩至12%。

2-光伏逆变器拓扑结构的演化及热管理

光伏逆变器拓扑结构的演化底层逻辑由 “效率-功率密度-成本”驱动:

·损耗机制变迁:从导通损耗主导(H桥)→开关损耗核心(NPC)→高频磁件/电容损耗(MMC)→SiC软开关下电磁兼容损耗占比超60%,推动散热焦点从“均温”转向“超高热流密度管理”;

· 功率密度跃迁:硅基IGBT的物理极限(20kHz/3kW/L)被SiC器件突破(100kHz/50kW/L),倒逼散热方案从风冷→热管→液冷→微通道相变冷却的四级跳;

·成本动态平衡:散热系统成本占比从H桥到SiC逐渐减低,但单位功率散热成本反而增加,需通过 拓扑-封装-散热协同设计 重构热边界,最终实现LCOE下降。

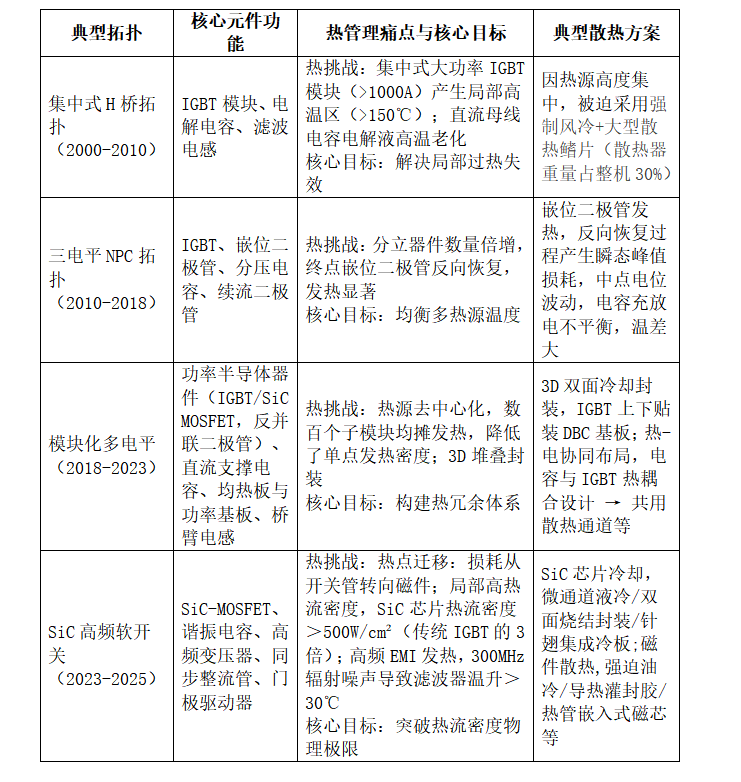

表1:光伏逆变器拓扑结构的演化历程及热管理

面对光伏逆变器功率密度持续跃升、热流密度不断突破的工程挑战,散热方案需系统性升级:

·风冷向液冷演进:应对新型芯片高热流密度特性,显著降低核心温度;

·热管与相变技术结合:有效抑制模块化系统的热冲击,延长关键部件寿命;

·协同设计控本:通过电气与热管理的深度集成,优化散热系统占比。

作为热管理合作伙伴,我们迈泰技术专注 芯片级冷却技术与 系统级热阻优化,为光储系统提供可落地的散热解决方案。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

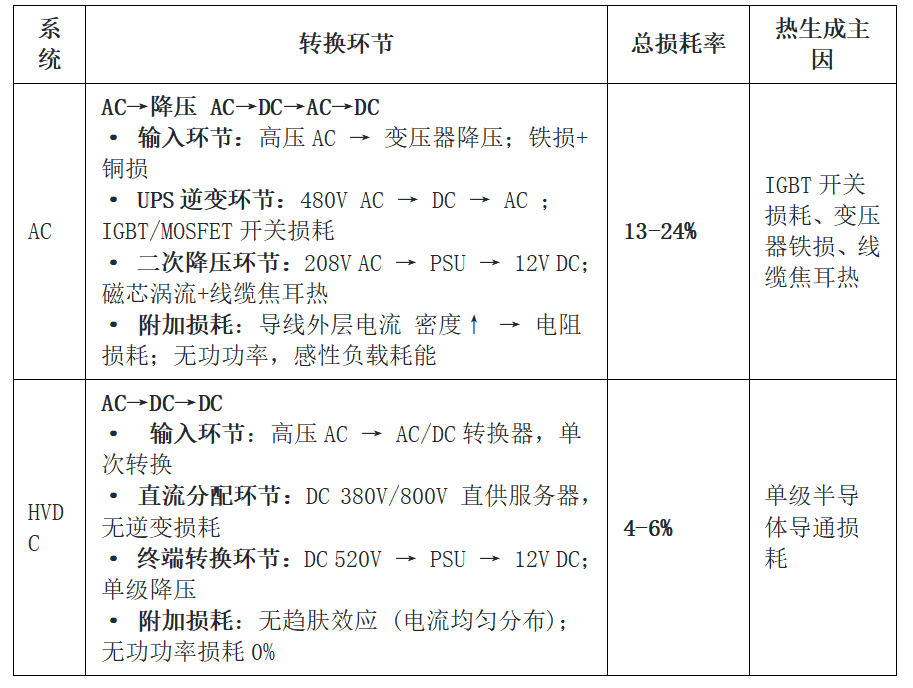

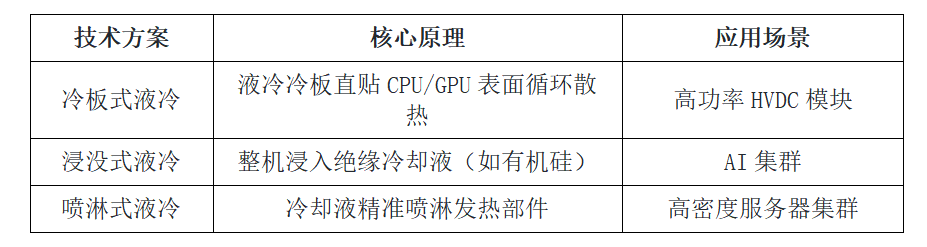

本文尝试梳理AI算力爆发背景下,HVDC系统散热技术的革新路径,聚焦液冷协同与材料升级两大方向。内容源于行业公开资料整理,若有疏漏之处,恳请指正。

1- HVDC崛起与散热需求升级的必然性

AI算力爆发式增长显著提升了数据中心功率密度(单机柜超100kW),推动了对高效率供电系统的需求。传统UPS面临效率与占地挑战,而HVDC系统凭借其高效、低损耗、小体积和高可靠性优势,正迅速成为AI数据中心的主流供电方案。这直接驱动了HVDC市场的快速增长和在AI数据中心渗透率的飙升。同时,AI需求也促使HVDC技术向更高电压等级发展(如750V、1000V系统),以进一步提升效率和功率承载能力。

a.AI算力爆发与能效苛求

为满足高能效标准(如数据中心PUE≤1.5/≤1.3),HVDC散热技术需实现:

·高效冷却设计,采用液冷技术应对高功率密度;精确控制冷却参数。

·热传输介质优化,优先使用去离子水,特殊场景选用防相分离的稳定流体(如PCD)。

·散热器性能升级,采用高导热材料;特殊流道设计提升热交换效率。

·动态温控与监测,实时监控关键点温度;配备诊断设备预判故障。

·冗余与可靠性设计,如:冷却系统N+1冗余配置,双路冷冻水管网防单点故障。

·应急散热能力,支持极端工况散热。

·环境适应性,确保15-35℃环境温度下稳定运行,兼顾防潮通风。

b.第三代半导体(SiC/GaN)的应用深化

AI算力激增推动800V高压直流架构成为数据中心新趋势:

·SiC/GaN凭借 高功率密度、高频开关、低损耗 特性,逐步替代传统硅基器件。

·显著提升系统效率。

·降低材料成本并增强可靠性。

c.HVDC vs. AC供电的能效优势及其散热影响

HVDC架构对散热系统的要求主要体现在高功率密度、高效冷却方式、冗余设计、环境适应性、能效优化以及快速故障恢复等方面。这些要求共同决定了HVDC系统在设计和运行中的复杂性与挑战性。

表1:HVDC vs AC 能量转换损耗的根源差异分解

2- 革新核心:液冷协同与材料升级的解决方案

a.液冷系统:从边缘到主流的代际跃迁

液冷渗透率从快速跃升,AI算力驱动GPU功耗达1000W倒逼风冷转型,边缘场景下沉需适应-30℃~60℃极端温域。

表2:技术路径的代际跃迁

b.材料升级:应对极限热挑战的关键突破

材料升级推动散热效能突破:通过高导热界面材料优化晶闸管热管理,结合氮化铝陶瓷基板(热导率≥180W/mK)强化SiC/GaN器件散热能力,并采用复合液冷结构支撑高功率密度。系统层面通过N+1冗余液冷架构、智能温控策略及800V耐压管路设计,实现安全高效的协同散热。

3-技术挑战与散热产业链机遇

a.关键挑战:标准化与兼容性瓶颈

芯片级冷板接口不统一与机柜级管路耐压差异(500V~800V)导致兼容性差,推高改造成本;冷板式与浸没式技术路线割裂,冷却液绝缘标准缺失加剧产业碎片化;运维环节存在漏液检测机制不足、冷却液性能衰减标准空白等隐患,根源在于芯片商/服务器商/液冷方案商三方生态割据,形成责任模糊的"孤岛化"困局。

b.协同机遇:技术协同与产业协同

芯片层推动冷板接口标准化,系统层通过AI温控算法联动HVDC负载与冷却流速;产业层依托ODCC建立接口与冷却液标准,以模块化整机缩短部署周期;创新冷却液再生技术及设备租赁模式降低成本,并通过保险机制覆盖漏液风险,实现技术-产业-金融三维协同。

当前HVDC散热技术仍面临标准化、兼容性等挑战,但产业协同已显现破局曙光。本文仅作阶段性观察,期待与业界同仁共同探讨优化方向。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

对于散热器制造,材料选型与铲齿精度是决胜关键。面对超薄齿、高密齿的严苛需求,核心挑战在于:如何平衡材料导热性、成本与可加工性?如何突破设备极限,实现微米级稳定精度,确保齿形一致性与散热效能?这直接决定了产品性能、成本竞争力与量产良率。

1-工艺核心问题与挑战

a.工艺本质:分层铲削(粗→精加工)形成高密度齿片

分层铲削通过粗加工快速去除余量、精加工保证齿形精度,但面临三大矛盾:

· 热变形控制:粗加工产生的高切削热导致薄壁齿片局部膨胀,精加工时需补偿变形量,否则出现椭圆度误差(如散热齿间距不均)。

· 应力平衡:分层加工中残余应力累积引发齿片翘曲,尤其铝材(导热系数高但屈服强度低)需通过"小切深快进给"策略降低切削力。

· 精度传递:粗加工遗留的锯齿状残留材料,增加精加工刀具负载,易引发颤振导致齿厚超差。

b.两大痛点

· 材料选择:材料选择需平衡导热性、加工性和成本,通过性能对比和选型决策,结合材料改性与成本控制,实现协同优化。

· 设备精度:设备精度优化通过抑制切削热变形、刀具磨损与误差,采用创新刀具及热-力耦合误差补偿,提升加工精度与刀具寿命。

2-材料选择:决定性能与成本的关键

a.导热需求主导

· 高热通量场景(>100W/cm²):首选铜(导热系数380W/m·K),热承载能力比铝高30% 。

风险控制:酸洗去氧化层(10% HNO₃)+ 苯并三氮唑油膜防二次氧化,降低刀具磨损40% 。

中低热通量场景(<80W/cm²):纯铝优先(导热系数210W/m·K),满足大部分消费电子需求,成本仅为铜的30%。

b.成本限制优化

· 成本敏感型项目,材料减薄(如,铝基板从4mm→2mm);废料循环(铜屑回收率>95%);局部复合设计(仅热源接触区用铜)。

· 替代方案,纯铝+热管设计,等效导热系数200–220W/m·K。

c.加工难度妥协

· 高齿片需求(>70mm),选纯铝,齿高极限120mm,抗弯折性强于铜 ;预处理,铝材预退火(降低残余应力),减小硬度波动 。

· 高精度齿形(齿厚<0.5mm),选6系铝,AL6063经软态加工后时效硬化,齿厚可控至0.25mm ;禁忌,避免直接加工硬态铜材(易崩齿),需低温预处理。

3-设备精度优化:提升良率的核心

设备精度是铲齿工艺实现高密度齿片、控制变形与磨损的核心抓手。

铲齿设备精度优化思路:

· 核心精度提升:数控化替代, 用数控系统取代机械传动,消除分度误差;热变形抑制, 采用冷风切削技术,并结合补偿技术,主动控制加工热变形;刀具强化, 应用CBN涂层并进行几何结构优化,提升刀具抗崩刃能力。

· 关键成果:设备加工精度达到 ±0.003mm (微米级);成功支撑厚0.3mm、齿高120mm 的极限齿轮设计;生产良率实现 65% 到 95% 的大幅跃升。

综上所述,精准的材料匹配与极致的铲齿精度是散热器制造的核心壁垒。优选材料保障性能基础,而微米级精度的设备(数控化传动、热变形抑制、耐用刀具)则是实现高良率、支撑极限齿形设计的唯一路径。持续优化此双核心,并前瞻布局先进精密控制技术,方能稳固散热器加工的市场领先地位。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

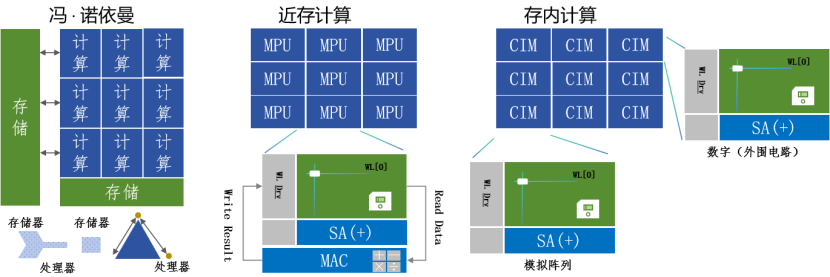

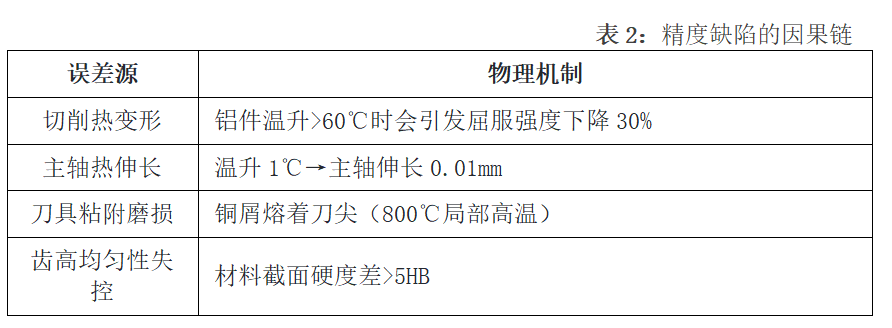

AI服务器的算力狂飙正遭遇“热束缚”——芯片功耗密度突破1000W/cm²(如英伟达H100),机柜功率密度从2.4kW跃升至120kW,传统03风冷方案触及8-10kW的物理极限。这一“散热危机”的底层逻辑,是芯片架构的量子效应困境(3nm以下漏电率激增)、数据搬运的能耗失衡(占系统功耗90%以上)与大模型训练的指数级需求(GPT-4单次训练耗电32.4TWh)共同作用的结果。面对政策强约束(中国PUE≤1.25)与能效倒逼,液冷技术从边缘实验走向主流,成为解锁AI算力的关键密钥。

1-AI服务器散热需求的底层逻辑

a.芯片架构与功耗革命

AI芯片的算力密度(单位面积或单位功耗下的算力输出)与功耗是衡量其效能的核心指标。以下通过三个典型芯片案例进行分析:

算力持续升级中,芯片性能因散热与能效的物理约束无法充分释放。这种“功耗墙”现象源于:

· 散热滞后性,芯片功耗密度增速(>1000W/cm²)远超散热技术迭代速度,传统方案触及物理极限。

· 能耗结构失衡,物理层面,3nm以下量子隧穿效应削弱能效提升,3D堆叠使散热效率骤降30%-50%;架构层面,数据搬运能耗占比超90%,算力增速(750倍/2年)与内存带宽(1.4倍/2年)严重失调;应用层面,大模型参数爆炸(如GPT-4训练耗电32.4TWh)与动态负载(瞬时功耗超TDP 200%)加剧散热压力。

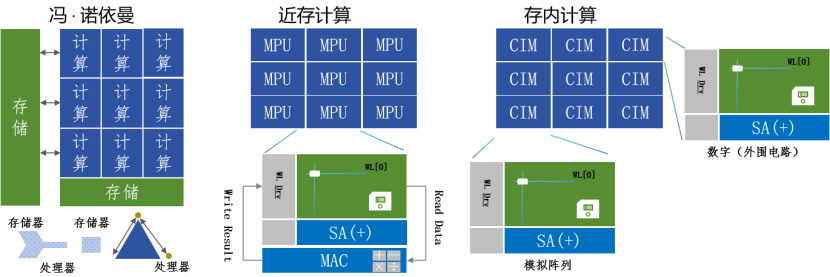

图1:存储和计算的融合形态

b.机柜功率密度的跃迁

机柜功率密度正经历从通用计算到AI驱动的超密度革命,从“机房适配设备”到“设备定义机房”的范式重构,AI算力需求倒逼基础设施跨越式升级。

· 指数级跃迁,2011-2024年全球平均密度从2.4kW/柜升至9.5kW/柜(CAGR≈12%),AI智算中心推动密度突破120kW/柜(如英伟达GB200 NVL72),2030年或达MW级。

· 核心驱动,AI芯片功耗激增(H100单卡700W→GB200单卡1200W)与大模型训练需求(GPT-4单次训练耗电32.4TWh)形成“双螺旋效应”,迫使机柜密度匹配算力暴增。

· 技术突破,风冷极限(8-10kW)被液冷取代,冷板式(20-50kW)、浸没式(50-120kW)支撑高密度;供电系统升级至高压直流(HVDC),效率>98%;空间利用率提升40%(取消风道),液冷使PUE降至1.08。

c.政策与能效驱动

· 中国“东数西算”工程:强制要求东部枢纽节点PUE≤1.25,西部≤1.2,倒逼液冷技术普及。以内蒙古枢纽为例,采用浸没式液冷可将PUE降至1.08,年节电超2000万度。

· 全球碳排放法规:欧盟CSRD指令要求数据中心披露全生命周期碳足迹,加州《气候企业数据问责法》将范围三排放纳入强制披露,液冷技术因减少间接排放(如制冷剂泄漏)成为合规关键。

· 经济效益杠杆:液冷数据中心相比风冷节省30%-50%的制冷能耗,结合峰谷电价差异,投资回收周期可缩短至3-5年。

2-散热技术演进与技术路线分化

a.液冷技术:从边缘到主流

液冷从“边缘实验”到“散热基座”的跃迁,是算力密度与能源效率的再平衡,重构数据中心价值链。

· 演进历程,边缘化阶段(1960s-2010s),仅用于超算/军工(如Cray-2),受限于材料腐蚀性与高成本;突破期(2010s-2020s),GPU热密度突破500W/cm²(英伟达P100)与政策(中国PUE≤1.25)驱动商用,冷板式改造成本降至风冷1.2倍;主流化(近2-3年),AI机柜功率密度突破120kW(如英伟达NVL72),液冷TCO较风冷低12.2%,回收周期缩至3-5年。

· 演化逻辑,技术逻辑,从“风冷适配芯片”转向“芯片定义散热”,液冷成为算力释放的核心杠杆;产业逻辑,形成“政策驱动标准→标准降低成本→成本推动普及”的正向循环;生态逻辑,重构数据中心价值链,使冷却系统从“成本中心”变为“能效资产”。

· 技术路线分化,液冷技术分化源于散热效率与改造成本的博弈,冷板式液冷以兼容性优先,通过局部改造平衡成本与风险,适配中密度场景;浸没式液冷追求物理散热极限,以系统重构突破热密度墙,但面临材料与运维挑战;喷淋式液冷探索芯片级精准控温,为光计算等敏感场景铺路。液冷技术分化本质是 “散热效率-改造成本-运维复杂度”不可能三角的权衡结果。冷板式液冷胜在平衡性,浸没式液冷追求物理极限,喷淋式液冷瞄准精准控温,三者共同推动液冷从“技术选项”变为“算力基座”。

b.芯片级散热技术呈现多维突破

芯片级散热技术正经历“材料-结构-控制”三位一体革新,短期以3D微流道与冷板液冷主导(支撑千瓦级TDP),长期依赖量子散热与光热协同突破物理极限。其发展直接决定AI算力释放效率与数据中心能效演进。

· 材料,金刚石/石墨烯逼近物理导热极限,相变材料解决瞬态热冲击。

· 结构,微流道与冷板从“外部贴附”转向“芯片内嵌”,散热路径更短、效率更高。

· 控制,固态主动散热芯片突破体积限制,AI动态调控实现“热-算协同”。

· 核心趋势,三者融合推动散热从“被动导热”向“芯片级主动控温”演进,支撑单芯片千瓦级TDP需求。

散热技术的演进已从“单点创新”升维至“系统重构”:冷板式液冷以兼容性主导存量改造,浸没式液冷突破物理散热极限,芯片级喷淋技术探索精准控温,三者共同构建分层散热体系。随着量子散热与光热协同技术走向商用,未来将支撑单机柜MW级超密度算力。这一进程不仅是散热范式的革命,更驱动数据中心从“能源消耗者”转向“能效资产”——据测算,全面液冷化可助全球数据中心2030年减碳4.5亿吨。散热,正从成本中心蜕变为AI算力经济的核心基座。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

当你在电子设备中看到那片精密如梳齿的散热器时,或许想不到:它的性能巅峰,早在铲刀接触金属之前就已经被注定了。大厂为啥愿意花大钱搞材料预处理?因为这个步骤能直接让散热器升级:切铝省力20%,铜散热器多用3年,甚至能一口气切出12厘米高的散热片。本文介绍怎么通过科学手段给金属"按摩松骨",让硬邦邦的金属乖乖听话变身完美散热器。

1-为什么预处理是铲齿散热器的“隐形引擎”?

a.高精度散热器的制造挑战

·残余应力集中:原材料轧制或铸造过程残留的应力,在铲削时释放导致基板翘曲。

·材料软化:铝、铜等材料在切削过程中因温升(铝40–60℃,铜80–120℃)导致局部软化,引发齿片塌陷或毛刺增多。

·表面氧化,铜材在空气中易氧化生成CuO层(硬度高、脆性大),加剧刀具磨损,进而寿命缩短。

b.预处理——从“金属原料”到“精密齿片”的关键桥梁

·材料性能优化,对铝材和铜材分别进行再结晶退火,消除轧制过程中产生的残余应力,材料硬度均匀性可以显著提升。

·表面状态控制,采用化学清洗去除材料表面的氧化层,如铜材可使用10% HNO₃酸洗,处理后表面粗糙度可降至0.4μm,有效减少刀具粘附;或者对铝材做钝化处理,如铝材经阳极氧化形成5–10μm厚的Al2O3膜,防止在加工过程中发生二次氧化。

图1:散热器化学清洗

c.预处理技术如何将加工效率提升?

·缩短加工周期,预处理后材料切削阻力降低,允许提高进给速度。

·减少返工率:应力预释放使基板平面度合格率大幅提升,省去二次校形工序。

2-预处理技术的基础:材料科学与工艺的融合

预处理技术的核心在于基于材料特性定制工艺逻辑,以解决铝、铜等高导热材料在铲齿加工中的固有矛盾。

a.材料特性决定预处理逻辑

·铝材预处理,退火需300–350℃×2h,可消除轧制应力,使硬度均匀性提升40%;表面处理可选择阳极氧化生成5–10μm的Al₂O₃膜或化学钝化(铬酸盐处理),抑制加工氧化。

·铜材预处理,退火在500–600℃×1h,能软化材料,硬度从80HB降至45HB,降低切削力30%;酸洗用10% HNO₃溶液去除氧化层,当CuO厚度超1μm时,刀具磨损率会增加50%。

b.核心矛盾:高导热材料的加工悖论

·矛盾点,高导热性(如铜380 W/m·K)是散热器核心优势,高导热导致切削热快速传导至刀具,加速磨损(铜加工刀具寿命仅为铝的1/3)。

·预处理方案,热导率与加工性平衡,如对铜材进行低温预处理以降低切削温升或梯度材料设计;氧化层管理,如保留铝材的致密Al₂O₃膜,降低摩擦;对铜材酸洗后涂覆苯并三氮唑油膜,阻断二次氧化。

3-核心预处理方法

a.机械预处理:为加工“铺平道路”

表面清理(喷砂/抛光),去除氧化层、油污及毛刺,提升表面粗糙度(Ra值),增强涂层附着力或后续酸洗效果。

b.化学预处理:激活材料表面活性

通过物理清洁(去污)、化学改性(转化膜形成)和表面性能提升,使材料表面从惰性状态转变为高活性状态。其核心在于平衡表面粗糙度、化学官能团密度与耐蚀性,从而为后续工艺提供理想基底。

c.热处理:重塑材料微观结构

通过精确控制材料的加热、保温和冷却过程,实现微观结构重组与优化,其核心在于利用热激活机制驱动原子扩散、相变和缺陷重组,从而赋予材料全新的性能特征。

d.成分控制:从熔炼到成型的全流程管理

成分控制是材料制造的核心技术,通过精选原料、熔炼精准调控及成型参数优化,结合数字化检测,精细化控制波动,提升性能。

4-铝 vs 铜:差异化的预处理策略

铝与铜因其物理、化学特性的显著差异,预处理策略需针对性设计,以解决各自加工痛点。

4-预处理如何成为效率“放大器”?

a.与铲齿加工的协同

·降低刀具磨损:预处理后表面残留硬质氧化物减少,延长铲齿刀具寿命,加工高密度齿片的崩齿率下降。

· 提升加工精度:喷砂预处理消除材料内应力,使铲齿高度误差从±0.5mm降至±0.1mm,满足高倍齿(齿高/基板厚度≥10)需求。

b.与表面处理的协同

·增强涂层结合力:钝化预处理后,可显著提升涂层附着力测试通过率。

· 降低接触热阻:预处理形成均匀微孔结构,使散热器与热管焊接界面热阻降低15%-20%。

c.与表CNC加工的协同

·减少二次加工缺陷:化学清洗去除油污后,CNC铣削铝材的毛刺率下降60%,攻牙滑牙缺陷减少50%。

d.预处理对生产效率

·良品率提升:通过优化化学和机械预处理工艺,铲齿散热器及CNC加工的良品率显著提高,产品质量得到保障。

·加工周期缩短:预处理后,铝材加工无需单独去毛刺,单件加工时间大幅缩短。自动化喷砂线处理速度提升,生产效率显著提高。

·能耗与成本降低:采用机械预处理替代化学酸洗,加工能耗降低。预处理后材料硬度降低,模具损耗减少,生产成本有效降低。

预处理技术的突破,离不开材料与设备的底层支撑。铲齿工艺的核心竞争力,恰恰源于这两大基础的科学选型与极致优化:铲齿工艺的核心竞争力:材料选择与设备精度优化

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

随着全球能源结构转型加速,储能系统在电力调频、新能源消纳等场景中的作用日益凸显。储能PACK箱体作为核心载体,其环境适应性设计需兼顾极端气候耐受性、结构强度与长期可靠性。本文从场景需求出发,梳理气候适应性关键技术路径,分析设计挑战与创新方向,为高环境适应性储能箱体开发提供参考。

1-储能市场场景分化与精细化经营趋势

a.场景分化图谱:区域特征与技术需求的耦合

储能市场呈现显著区域分化,技术方案需适配气候条件、电网特性及应用场景:

·极端气候场景:

高温沙漠环境:箱体需耐受50℃以上高温(集装箱内部热岛效应可达53.3℃),通过IP55/IP67防护等级认证,并采用防沙棉、密封胶等多重措施抵御风沙侵蚀。

高海拔/低温环境:在-40℃低温下,需集成电芯预加热技术,优化液冷系统冷量衰减(运行下限扩展至-30℃),并强化电气绝缘以应对空气稀薄导致的电弧风险。

·电力系统适配场景:

欧洲电网调频需满足动态功率调节(47.5-51.5Hz范围),兼容辅助服务市场要求;北美光储融合项目需支持1500V直流架构与快速充放电切换(≤100ms),并通过热失控蔓延测试确保安全性。

·工商业储能场景:

紧凑型设计通过电芯直接集成技术(空间利用率提升至33%),模块化方案支持灵活扩容(15-921kWh),并集成智能运维功能以降低全生命周期成本。

b.精细化经营策略,从产品交付到价值服务的转型

·定制化技术方案:针对孤岛地区输电成本高的问题,配置4小时以上长时储能系统可减少电网升级投资30%;构网型储能系统支持多场景兼容,提升电网稳定性。

·全生命周期服务:通过LCoS(平准化储能成本)模型优化初始投资与运维成本,智能运维平台整合电价数据与负荷预测,动态优化充放电策略,提升收益15%以上。

2-气候耐受性关键技术路径

a. 热管理-结构协同设计

·液冷技术主导:

冷板式液冷:采用蛇形微通道冷板(流道宽度≤2mm),温差控制≤3℃,改造成本较风冷系统增加15%-20%,电芯寿命提升30%。

浸没式液冷:通过介电冷却液直接散热,热传导效率提升50%以上,但需平衡冷却液成本与维护复杂度,多用于高端场景。

·结构集成优化:

流道-底板一体化设计结合搅拌摩擦焊工艺,焊缝强度达母材95%,抗震性能满足IEC标准,集装箱减重18%。

b.气候侵蚀防护体系:材料革命与密封技术创新

·材料选择:

铝合金箱体通过阳极氧化实现C5级防腐,盐雾测试达3000h无腐蚀;碳纤维复合材料减重35%,抗风压能力达2.5kPa。

·密封技术:

动态密封结构采用EPDM橡胶、聚氨酯发泡层与硅酮密封胶三重防护,激光焊接工艺使气密性达10⁻⁷ Pa·m³/s。

c.极端气候应对策略:主动防御与智能调控

·高低温适应性:

复合保温层(导热系数≤0.018W/m·K)结合电加热膜,维持箱体内外温差50℃以上;脉冲自加热技术能耗降低70%。

·抗风沙设计:

正压通风系统(除尘效率≥95%)与仿生微沟槽表面设计,沙尘浓度控制≤0.1mg/m³,表面积尘量减少60%。

3-储能Pack箱体设计核心挑战与需求

a. 环境适应性定义

需满足机械强度(抗冲击、抗震)、化学稳定性(耐盐雾、抗紫外线)及热管理效能等多维度指标。

b. 结构强度需求

内部隔板与加强筋优化应力分布,均载结构平衡压力;铝合金框架结合复合材料面板实现轻量化(减重31%)与高刚性。

c. 市场驱动因素

政策导向:国内风光大基地建设推动高环境标准;海外市场强制认证(如澳洲AS/NZS 4777.2)加速技术升级。

经济性需求:液冷系统降低LCoS,高充放电倍率(1C)场景下优势显著。

4-多维度结构强度设计体系

a. 材料创新与复合结构

高性能铝合金(抗拉强度≥270MPa)与镁合金支架协同减重;复合三明治结构(铝面板+泡沫铝芯层)兼顾轻量化与抗冲击性。

b. 模块化与可扩展架构

标准化接口支持电池簇快速扩容,柔性制造工艺(搅拌摩擦焊/激光焊接)提升产线兼容性,适配多尺寸电芯混装需求。

储能PACK箱体的环境适应性设计是技术迭代与场景需求深度耦合的产物,需通过多维度结构优化与气候防护技术创新实现可靠性跃升。未来技术发展将聚焦智能动态温控(如AI驱动的热管理策略)、低碳材料工艺(生物基复合材料应用)及全球标准化认证(多区域气候工况覆盖),以应对极端环境与多样化市场挑战。通过强化结构强度、轻量化设计及全生命周期成本优化,储能系统可有效支撑新能源规模化应用,为全球能源体系低碳转型提供高适应性的基础设施保障。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

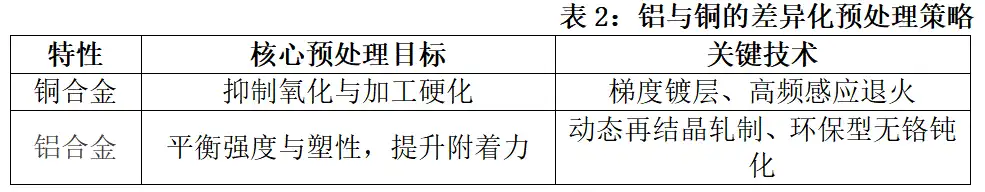

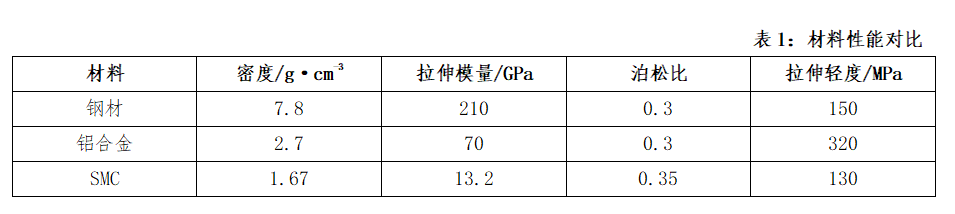

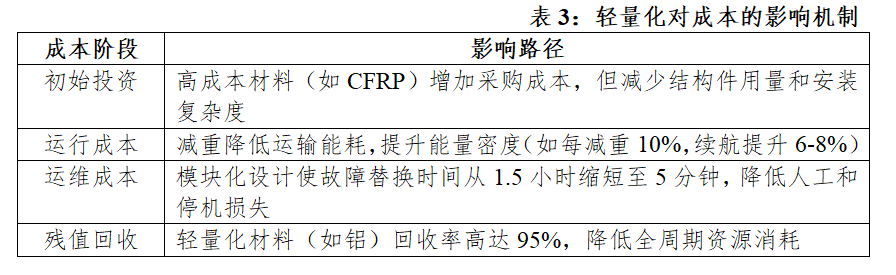

储能PACK箱体的主材应用历程本质上是轻量化需求、热管理效率与全周期成本的平衡过程。从钢材到铝合金再到复合材料,每一次迭代均伴随工艺创新(如焊接技术、模块化设计)和功能集成(液冷+防火+密封)。

1-轻量化逻辑

a.材料选择与替代逻辑

· 初期阶段(2020年前):钢材与镀锌钢板主导

材料特性:钢材(密度7.8g/cm³)因低成本与成熟工艺成为主流,但重量大、易腐蚀,镀锌钢板(抗沙尘磨损Class 4)长期使用仍面临锈蚀风险,维护成本高。

应用局限:箱体重量占比超40%,系统能量密度低,定制化焊接导致安装周期长,难以匹配分布式储能需求。

· 突破期(2020-2024年):铝合金与不锈钢的多元化应用

铝合金普及:密度(2.7g/cm³)较钢降65%,导热系数237W/mK适配液冷技术,一体化设计通过搅拌摩擦焊集成液冷流道与底板,减少连接件并提升密封性;典型双层结构方案(外层镀锌钢板抗风沙+内层铝镁合金控温)实现系统效率提升12%。

不锈钢优化:316L不锈钢耐氯离子腐蚀超2000小时,结合硅胶密封形成高湿度场景解决方案。

· 成熟期(2024年至今):复合材料与功能集成

SMC复合材料:玻璃纤维增强(密度1.67g/cm³)重量仅为钢材21%,模压成型实现异形结构设计;“三明治”复合结构(SMC+气凝胶)耐火极限达2小时,同步减重30%。

碳纤维探索:拉伸强度300-1200MPa,密度1.5-2.0g/cm³,受限于成本(钢材5-8倍)多用于高端场景局部强化。

材料轻量化的核心在于密度-强度比优化,参见下表材料性能对比,通过替代高密度材料(如钢)为铝合金或复合材料,可在保证强度(如通过拓扑优化补偿强度损失)的前提下显著降低重量,进而提升能量密度和运输效率。

b.结构优化技术

结构优化通过创新设计方法重构箱体力学结构,在维持承载性能的同时精简材料与工艺。铝合金拼焊技术采用先进焊接工艺实现壁厚显著减薄,结合流道与框架的集成设计减少冗余连接节点,降低密封失效风险。冲压钎焊技术通过模具成型工艺打造一体化曲面薄壁结构,大幅减少传统紧固件使用量,并融合表面处理技术增强耐腐蚀性,有效降低全生命周期运维成本。两项技术通过减少加工环节与材料冗余,协同提升生产效率和结构可靠性,显著降低单位储能成本,同时保障设备在复杂工况下的长期运行稳定性。

c.制造工艺创新

结构设计优化增效:

一体化集成:液冷流道与箱体底板融合,减少30%连接件,密封性与散热效率双提升。

模块化设计:标准化接口兼容多元材料,安装效率提升50%,适配多场景快速部署。

先进工艺降本提效:

高精度自动化:激光切割+机器人焊接,材料利用率提升15%,生产周期缩短40%。

数字化仿真:CAE优化工艺参数,试模次数减少50%,良品率超98%。

2-全周期成本控制的核心要素

a.成本构成模型

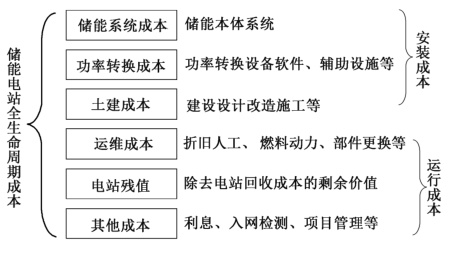

全周期成本(LCOS)包括:

· 初始投资成本(C_mv) :设备采购(占50%以上)与施工。

· 运行成本(C_ps) :充电电费、人工管理、能量损耗(如转换效率75%时充电成本增加33%)。

· 运维成本(C_om) :设备维护、故障修复、备件更换(占生命周期成本20-30%)

公式表达:CEss=α⋅EBESS+β⋅PBESS+Cps+ComCEss=α⋅EBESS+β⋅PBESS+Cps+Com

其中,轻量化通过降低E(能量需求)和P(功率需求)直接影响初始投资

图1 储能电站全生命周期成本

b.轻量化对成本的影响机制

3-平衡轻量化与性能的关键策略

a.强度与重量的平衡

局部强化:在应力集中区域(如螺栓连接处)采用钢材补强,其他区域使用轻质材料。

仿生结构设计:如叶脉状液冷管道,在减重同时提升散热效率。

b.散热性能优化

材料导热系数匹配:铝合金(237 W/mK)优于钢(50 W/mK),适用于液冷系统。

热管理集成:将冷却板与箱体一体化设计,减少额外散热组件重量。

c.防护性能保障

多层密封:采用胶体密封+机械压紧的双重防护,满足IP67标准。

防火设计:“三明治”舱体结构(耐高温层+防火层)实现2小时耐火极限。

储能PACK箱体轻量化与成本控制的底层逻辑是通过材料替代-结构优化-工艺革新的三维协同,在保证性能的前提下降低全周期资源消耗。其本质是能量密度提升、运维效率优化与材料循环利用的综合博弈,需在技术可行性与经济性间找到最佳平衡点。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

储能行业的安全进化是技术迭代与安全标准协同驱动的系统性变革。从散热路径重构、材料与结构协同防护到热管理集成化,这一进程体现了行业对热失控防护的底层逻辑——从被动防御向主动抑制转变,从单一维度到多层级耦合升级。

1-储能技术的"不可能三角"及核心矛盾化解策略

a.储能技术的"不可能三角"矛盾集中表现为多重维度的相互制衡:

储能技术发展面临能量密度、安全性与成本之间的复杂平衡。高活性材料虽能提升能量密度,但也显著加剧热失控风险;而通过系统级安全设计(如液冷控温技术)虽能降低风险,往往伴随能量密度的折损。此外,主动防护系统和本质安全技术的引入虽能提升安全性,却显著增加了非电池部分的成本。这些矛盾揭示了储能技术演进中需破解的多重约束。

b.核心矛盾化解策略:

材料创新:新型电解质材料的应用显著延缓了热失控传播时间,同时兼顾高能量密度;钠离子电池通过负极材料优化在降低成本的同时保持了合理的能量密度;纳米化复合材料的引入则大幅提升了理论容量。

系统优化:先进的液冷技术通过精准温控显著提升了散热效率,同时降低了运维成本;动态可重构电池网络通过快速拓扑调整增强了系统可用性。

智能控制:人工智能预警系统通过多维度数据融合大幅提升了风险预测的准确性;能量转换技术的进步显著提高了系统效率。政策与商业模式创新加速了技术落地,例如共享储能模式降低了单点投资压力,梯次利用进一步优化了全生命周期成本。

2-演化规则

a.技术路径的融合创新

多源数据驱动的智能预警:新一代监测系统融合气体、压力、声信号等多维度传感器数据,结合动态失效模型与历史数据分析,显著降低了误报率并提前预警时间。

热管理与消防联动设计:液冷技术结合动态调温算法实现精准温控,消防系统与电池管理深度融合,形成多级联动策略,有效抑制热失控扩散。

材料与结构协同优化:耐高温绝缘涂层取代传统防火材料,显著延长了热蔓延阻断时间;结构设计中引入防撞强化与定向泄压通道,提升了抗机械冲击能力。

b.防护层级的逐渐深化

从电芯到系统的递进防护:电芯层级通过内嵌传感器实现早期风险监测;模组层级采用复合探测器与相变材料抑制局部热积累;系统层级构建协同监控平台,实现全生命周期防护。

从被动响应到主动防御:新标准推动主动防御技术发展,例如智能化电池管理系统通过动态阻抗分析在充电初期切断风险路径,主动防凝露技术消除环境隐患。

多维度协同防护:热-电-机械协同设计强化系统整体安全性;消防与运维协同监测覆盖制造、运输全环节,降低误报风险。

3-演化进程

a. 散热技术的迭代

液冷技术成为主流:液冷系统通过高效均温性显著降低电池簇温差,延长寿命并提升安全性;浸没式液冷技术进一步突破散热极限,支持高倍率充放电场景。

结构优化提升散热效率:多流道并行设计实现冷却液均匀流动,隔热与冷却功能集成阻断热蔓延路径。

b. 材料与结构创新

高安全材料体系:耐高温隔膜与成瓷涂层显著延缓热失控链式反应;轻量化复合材料在降低重量的同时提升结构强度与防护性能。

电芯与模组创新:新型电芯设计通过优化内部结构减少环流并延长寿命,模组集成技术提升空间利用率与散热效率。

c. 热管理集成化

系统级集成设计:一体化方案将电池管理、消防与热管理深度融合,支持灵活部署并适应极端环境。

智能化与协同控制:人工智能模型实时预测电池状态并优化能量分配,消防系统与热管理联动实现快速响应。

全生命周期管理:从设计到退役的闭环管理结合数字化监控与云端健康评估,显著提升系统可靠性。

结论

储能技术的安全革新不仅是技术迭代的成果,更是对能源系统底层逻辑的重构。通过材料、结构与智能化的深度融合,行业正突破能量密度、安全与成本的多重枷锁,构建起从微观电芯到宏观系统的立体防护网络。液冷技术与动态预警的协同,耐高温材料与轻量化设计的互补,以及全生命周期管理的闭环逻辑,共同勾勒出高安全、高能效储能系统的未来图景。随着量子材料、固态电池等前沿技术的突破,储能行业将加速迈向本质安全与规模应用的新纪元,为全球能源体系的低碳化、智能化转型注入持久动力。

热失控防护是安全保障的“主动防线”,而高承载结构则是支撑一切安全的“被动基石”。深入理解结构优化的新思路:电池包结构优化新思路:如何为587Ah电芯设计高承载Pack下箱体?

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

随着储能系统向大容量、高能量密度方向演进,储能PACK箱体的尺寸匹配与兼容性设计成为提升系统效率与可靠性的核心课题。本文结合最新工程设计案例、专利技术及行业趋势,从空间利用率、模块化兼容性、电芯排列与支撑设计三个维度展开分析。

1-空间利用率优化

储能系统集成的空间利用率提升,本质是技术迭代与场景需求的双向驱动。通过大容量电芯、模块化架构、液冷集成等技术的协同创新,行业正从“粗放堆叠”迈向“极致空间复用”。

a.大容量电芯应用:能量密度与效率跃升

思路概括:大容量电芯的应用本质是减少电池包内部结构层级,直接提升电芯到电池包的空间利用率。传统电池包采用“电芯→模组→电池包”三级集成模式,模组结构(横梁、纵梁、螺栓等)导致空间利用率低。大容量电芯通过拉长或增大单体体积,可直接跳过模组层级,采用CTP(Cell to Pack)技术将电芯直接集成至电池包。

技术核心:采用600Ah+超大电芯,减少电芯数量与连接点,提升单体容量。

b.空间复用与成本优化:从“组件堆叠”到“多维复用”

思路概括:空间复用与成本优化是一体两面的系统级创新,其底层逻辑在于通过结构简化、功能集成、材料迭代和标准化设计,打破传统储能系统的物理与成本边界。

结构层级的极致简化,空间复用的核心在于减少中间环节。如:高压箱二合一设计:江苏天合储能的专利技术将两个高压箱合并为一个,共享总正/负继电器和电气连接,减少30%的横向空间占用,同时降低15%的电气部件成本。

功能模块的跨域复用,结构件与散热通道一体化,如将液冷板与箱体底板集成,液冷管道与结构支撑共用空间,减少15%的独立散热组件;电芯本体作为结构件:比亚迪刀片电池通过长薄化电芯侧壁提供支撑强度,省去模组框架,空间利用率提升至60%-80%。

电气拓扑的深度优化,如,高压级联拓扑结构通过提高单体电池容量和电压等级(如华为智能组串式储能),减少并联回路数量,使电池堆物理空间缩小20%,系统响应时间缩短50%。;共享式继电器设计,江苏天合储能的二合一高压箱让两条线路共用同一继电器,减少50%的继电器数量和线缆长度,安装效率提升30%

2-电芯排列与支撑设计:承重、散热与抗振平衡

电芯排列的本质是空间利用率、热分布与机械稳定性的博弈,电芯的物理形态和排布方向直接影响空间填充效率:

a.优化电芯排列方式

倒置电芯设计:将电芯防爆阀朝下,使热失控排气与底部防球击空间共用,释放电芯高度空间,体积利用率大。

躺式电芯布局:优化电池包高度方向的空间利用,活性材料占比提升,体积利用率显著高于立式电芯。

超长薄型电芯:通过电芯长薄化设计减少单位体积内的电芯数量,提升成组效率。

b.散热与承重的耦合设计:旨在通过结构、材料、工艺的协同创新,实现高效散热与结构强度的双重优化。

结构设计路径:

集成化结构,如液冷板与支撑梁共形设计:将液冷流道嵌入铝合金支撑梁内部,减少独立组件,空间利用率提升;

分层分舱布局,将电池组、液冷系统、BMS分层堆叠,降低热流与机械应力的相互干扰;

仿生力学优化,如,蜂窝/波纹结构,在铝合金支撑框架中设计蜂窝或波纹芯层(如沐风网专利方案),通过形变吸收振动能量,同时优化散热路径。

材料创新路径:

导热-承重一体化,如,铝合金复合纤维材料(导热≥200 W/m·K,强度+30%);智能材料,相变填充层(PCM)吸热缓释,温差±1.5℃;轻量化阻尼:弹性硅胶垫层吸收振动(阻尼+40%)。

工艺实现路径:

精密成型工艺,如,挤压成型:用于制造复杂流道的铝合金液冷梁;

表面处理技术,如,在铝合金表面生成陶瓷氧化层,提升耐腐蚀性(盐雾测试≥1000h),同时增强散热效率(表面辐射率提高20%);

智能装配工艺,动态预紧力调节,如,集成压力传感器与电动执行器,实时调整螺栓预紧力(5-20kN),避免电芯过压损伤。

c.支撑结构的承重与抗振协同设计:支撑系统需满足静态承重(电芯自重+堆叠压力)与动态抗振(运输/地震冲击)的双重需求。

3-模块化与兼容性:标准化接口与可扩展架构

标准化接口适配多尺寸电芯的本质是通过机械、电气、热管理的协同创新,在统一平台上实现电芯规格的柔性扩展。当前技术已从静态兼容转向动态调节,未来将向智能化、轻量化、跨场景融合方向演进。

a.机械结构协同创新:

机械接口标准化:定义统一的连接装置尺寸。

模块化电池包/柜设计:通过标准化尺寸的电池单元(如280Ah、314Ah电芯)构建可扩展的模组和电池柜,支持不同容量需求的柔性组合。

b.电气系统动态调节

标准化通信协议与接口,如,BMS兼容性:制定统一的BMS(电池管理系统)通信协议,支持与不同厂商的PCS、电芯无缝对接;动态功率调节,通过虚拟惯量控制、多时间尺度优化算法,实现有功/无功功率的实时调整;以及自适应电气参数匹配设计。

c.热管理系统的智能化适配

分级热管理方案,如,电芯级采用阻燃高回弹泡棉、导热胶等材料,平衡隔热与散热需求,抑制热扩散;模组级集成液冷板与隔热层的一体化设计,提升循环寿命;系统级通过变频压缩机、多制冷支路动态调节制冷量。

智能化监控与预测,多传感器融合。在电芯极柱、大面等关键位置布置温度传感器,实现高精度温度采集;数字孪生技术通过云端监控和预测性维护,实时优化散热策略。

4-总结

储能Pack箱体空间优化已从单一结构改进转向多维度协同创新:

材料-结构-算法三元融合,如碳纤维箱体+CTP技术+AI排布算法的组合将成为主流。

模块化与标准化加速,以Pack为最小功能单元的标准化设计将推动行业降本增效。

热管理与空间利用深度绑定,浸没式液冷和动态温控技术进一步释放空间潜力。

高效的布局设计,必须考虑密封结构的空间与工艺约束。深入理解密封设计的基础,能让您的布局方案更具可行性:储能Pack全密封设计丨上篇:储能Pack箱体气密性设计

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

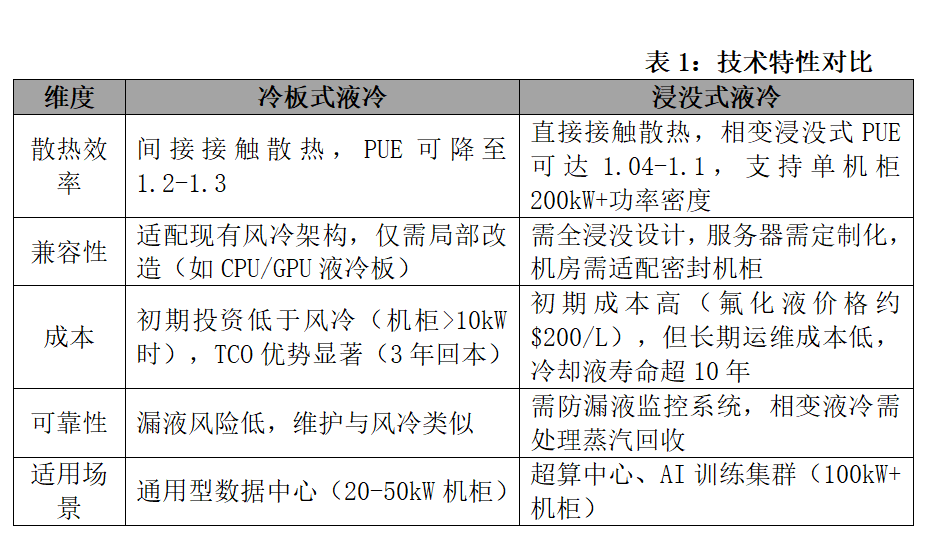

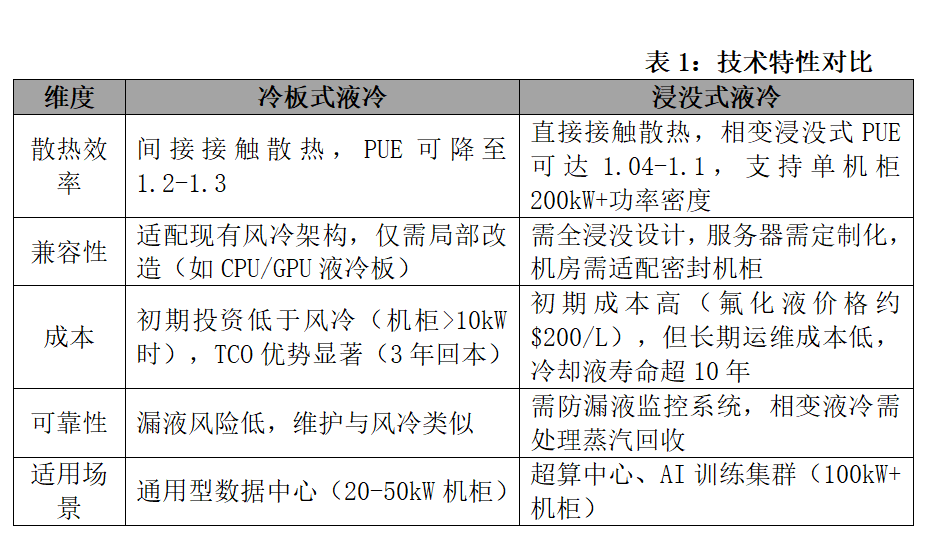

随着AI算力爆发式增长和数据中心功率密度持续攀升,传统风冷技术已难以满足散热需求,液冷技术凭借高效散热、节能降耗等优势成为必选项。在液冷技术中,冷板式与浸没式两大路径的竞争尤为激烈。本文将从技术特性、应用场景、成本经济性及未来趋势等角度解析两者的优劣势,并探讨其未来主导方向。

1-技术特性对比:冷板式兼容性强,浸没式散热效率更高

a.冷板式液冷:平滑过渡的“改良派”

兼容性强:无需对服务器结构进行大幅改造,可兼容现有风冷数据中心的基础设施,改造成本低、周期短。

安全性高:冷却液不与电子元件直接接触,泄漏风险较低,且可通过模块化设计(如快换接头、冗余管路)进一步降低风险。

成熟度高:冷板式技术已广泛应用于阿里云千岛湖数据中心、英特尔合作项目等场景,占据当前液冷市场90%的份额。

局限性:冷板式仅能覆盖部分高功耗部件(如CPU、GPU),其余热量仍需依赖风冷辅助散热,PUE值通常在1.1-1.2,略高于浸没式。

b.浸没式液冷:高效散热的“革新派”

浸没式液冷将服务器完全浸没于绝缘冷却液中,通过直接接触实现全器件散热。其核心优势包括:

极致能效:液体导热系数是空气的20-30倍,PUE可低至1.05,散热效率提升3倍以上。

空间节省:冷却系统体积仅为风冷的1/3,单机柜功率密度可达50kW以上,适合AI超算等高密场景。

静音环保:无需风扇,噪音降低90%以上,且无灰尘污染,延长设备寿命。

挑战:浸没式需定制化服务器、冷却液成本占比高达60%(如氟化液),且初期投资较高,生态兼容性待完善。

2-应用场景分化:中短期冷板式主导,长期浸没式潜力释放

a.冷板式:存量改造与新建IDC的“性价比之选”

老旧数据中心改造:冷板式可快速适配现有风冷架构,改造周期短、成本可控。例如,英特尔与比赫合作的模块化方案,通过标准化冷板设计降低部署难度。

中高密度算力场景:冷板式已支持单机柜130-250kW功率(如英伟达B系列GPU),满足多数AI训练需求。

b.浸没式:超算与绿色数据中心的“终极方案”

超高密度算力:下一代芯片(如英伟达Rubin系列)机柜功率将突破1000kW,浸没式成为唯一可行方案。

绿色节能需求:浸没式PUE逼近1.05,余热回收效率达90%(如联想方案),契合“双碳”目标政策。

c.市场格局现状

冷板式主导当前市场:2025年冷板式占液冷市场80%-90%,浸没式不足10%。并且已形成标准化接口(如英特尔的OCP冷板设计),浪潮、中科曙光等厂商方案兼容性强。国内“东数西算”工程要求新建数据中心PUE≤1.25,冷板式成为过渡首选。

浸没式蓄势待发:曙光数创C8000相变浸没方案实现PUE 1.04,阿里云“麒麟”数据中心验证单相浸没可行性。 英伟达B200 GPU(1000W+)等高功耗芯片倒逼浸没式应用,液冷算力密度提升30%-50%。 欧盟计划2028年禁用氟化液,国内碳氢/硅油冷却液研发加速(如中石化“昆仑”系列)。

3-权威观点PK

冷板派:冷板式是液冷普及的‘破冰者’,未来5年仍将承担80%液冷增量市场,浸没式需等待芯片功耗突破临界点。

浸没派:相变浸没是液冷的终极形态,冷板式仅是过渡方案。当单芯片功耗超800W时,浸没式将成为唯一选择。

中立派:技术路线分化反映算力需求分层,冷板服务‘东数’,浸没支撑‘西算’,双轨并行是未来十年主旋律。

4-行业机遇与策略

成本与生态博弈:冷板式短期占优,浸没式需降本破局。

冷板式:优化材料(铜铝复合)、提升加工精度(防泄漏工艺),推动模块化与标准化设计。

浸没式:研发高性价比冷却液(如单相浸没液)、兼容性机柜,联合芯片厂商定制散热方案。

技术储备:探索两相流冷板、智能监控系统(如AI动态调流),应对未来高功率需求。

5-结论

短期(2025-2027):冷板式主导通用场景,浸没式渗透率提升至15%-20%;长期(2030+):相变浸没式在高算力领域成为主流,冷板式退守中低密度市场。

胜负手:冷却液成本、芯片功耗跃升速度、国际环保政策。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

随着新能源汽车与储能产业的快速发展,轻量化、高安全性及高效热管理成为核心诉求。我司深耕铝合金材料加工领域,依托先进的材料选型、成型工艺与焊接技术,专注于电池托盘、液冷板、储能Pack箱及散热器的研发与制造。铝合金因其密度低(约2.7g/cm³)、强度高、耐腐蚀及优异导热性(热导率约150-220 W/m·K),成为新能源装备轻量化与热管理的理想选择。

1-铝合金材料选型及关键考量

不同产品对铝合金的性能需求差异显著,需结合强度、耐蚀性、焊接性及工艺适配性综合选材:

a.电池托盘

常用牌号:6061-T6、6005A-T6、6063-T6。

选型依据:

·需满足抗拉强度≥240 MPa(如6061-T6)以通过国标挤压、跌落及球击测试;

·焊接性要求高,需避免热裂纹(优先选用Mg/Si强化的6xxx系);

·耐腐蚀性通过阳极氧化或包铝工艺提升。

b.储能Pack箱

常用牌号:5083、6061-T6(兼顾强度与耐蚀性)。

选型依据:

·需承受振动与冲击载荷,屈服强度需≥200 MPa;

·表面处理要求高,避免电化学腐蚀。

c.液冷板

常用牌号:3003、6061/6063、6082。

选型依据:

·高导热性与耐腐蚀性;

·液冷流道需复杂成型,优先挤压性能优的6xxx系。

2-工艺性能差异与加工难点

铝合金的加工需适配其物理特性,尤其在切割、CNC、焊接及表面处理环节:

a.切割与CNC加工

难点:

·高精度孔加工易因材料延展性产生毛刺或变形(如台阶孔边缘突起);

·薄壁结构(如液冷板流道)需控制切削力以防翘曲。

解决方案:

·采用金刚石涂层刀具提升刃口锋利度,减少挤压变形;

·优化加工参数(如高转速、低进给)配合通用CNC设备实现稳定加工。

b.焊接工艺

核心挑战:

·氧化膜(Al₂O₃熔点2050℃)阻碍熔合,易导致气孔与夹渣;

·部分合金热裂纹倾向高,需控制线能量与焊丝成分。

优选工艺:

·TIG焊(交流电源):适用于薄板,通过“阴极清理”破除氧化膜;

·MIG焊(大电流+氦混合气体):厚板焊接效率高,热输入可控。

图4-电池托盘焊接

c.表面处理

·绝缘耐压涂层:应用于电池托盘与Pack箱内部,需通过耐压测试(≥3000V DC/1min),涂层厚度20-50μm,确保高压环境下的绝缘安全性;

·保温除湿涂层:针对储能Pack箱,采用疏水材料(如氟碳树脂)降低内部结露风险,达因值≥34以保证附着力;

·防撞保护涂层:用于电池托盘外壁,选用聚氨酯弹性体(硬度≥80 Shore A),抗冲击性能提升30%以上;

·阳极氧化:常规防腐处理,膜厚误差≤3μm,适配复杂结构。

3-审验性检查与设备适配性

为满足新能源行业标准(如GB/T31467.3、UL2580),需进行多维度验证与工艺适配:

a.审验性检查

·结构强度:通过有限元仿真验证托盘承载、挤压及球击性能(最大应力≤材料屈服强度);

·密封性测试:液冷系统采用氦检漏(泄漏率≤1×10⁻⁶ mbar·L/s)与循环压力测试(0.5-1.5MPa/5000次);

·涂层性能验证:

绝缘涂层耐压测试(5000V DC/60s无击穿);

防撞涂层通过落球冲击(1kg钢球1m高度)与盐雾测试(1000h无剥落)。

b.设备适配性优化

· 通用CNC设备改造:通过高精度夹具设计与动态补偿算法,实现薄壁件加工变形量≤0.1mm;

·焊接参数库:针对不同铝合金牌号建立标准焊接参数(如电流、送丝速度),降低调试周期;

·涂层自动化喷涂:采用多轴机器人喷涂,结合红外固化技术,涂层均匀性误差≤5%。

结语

铝合金在新能源装备中的广泛应用,既是材料科学的胜利,亦是工艺创新的体现。我司将持续探索高强、耐蚀、易加工的新型铝合金,并通过工艺革新推动电池托盘、液冷板等产品的性能升级,助力行业迈向高效、轻量化的未来。

了解了铝合金的广泛应用后,如何在一个关键部件上做出最优的材料抉择?本文以铲齿散热器为例,深度解析铝代铜背后的成本与性能平衡逻辑:为什么选择铝材替代铜材?铲齿散热器的成本与性能平衡攻略

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

在电子设备功率密度持续攀升的今天,散热设计已成为影响系统可靠性与寿命的关键环节。作为深耕热管理领域19年的专业制造商,我们结合典型工程案例与多物理场仿真经验,深度解析高功率场景下工程师易忽视的5大技术误区,并提供符合行业实践的解决方案。

误区1:高导热材料滥用,界面热阻计算偏差

典型问题:过度追求导热材料理论值,忽略界面接触热阻的工程实际。

案例解析:某车载激光雷达散热模组采用纯铜基板(导热系数401W/m·K),但未精确控制热界面材料(TIM)的涂覆厚度(设计0.1mm,实际波动±0.05mm),实测接触热阻达0.6°C·cm²/W,导致FPGA结温超标22%。经改用预成型导热垫(公差±0.02mm,热阻<0.03°C·cm²/W)并配合真空烧结工艺,结温降低17°C,MTBF(平均无故障时间)提升至10万小时。

优化方案:

材料选型:根据ASTM D5470标准实测TIM热阻,优先选用相变材料或金属填充弹性体。

工艺控制:采用自动点胶设备(精度±3%),确保厚度公差<10%,避免气隙产生。

误区2:风冷系统气流组织失配,局部热点失控

典型问题:盲目堆叠风扇数量,忽视流道阻抗匹配与边界层分离效应。

工程实例:某数据中心GPU集群采用4台12038风扇(风量200CFM),但因导流罩角度设计不当(90°直角弯折),实际有效风量仅达标称值的65%,局部温差达40°C。经CFD仿真优化,将导流罩改为渐扩式流道(扩散角<7°),并采用交错式鳍片布局(间距梯度从2mm增至3.5mm),整体风阻降低30%,热点温差控制在8°C以内。

核心策略:

流场设计:依据ISO 5801标准进行风洞测试,优化进出口面积比(建议1:1.2)。

动态调控:基于PWM风扇的Q-H曲线,匹配系统阻抗点至最高效率区间(通常为60-80%最大风量)。

误区3:环境防护设计失效,加速材料老化

典型问题:仅关注初始散热性能,忽略湿热/粉尘/盐雾等长期环境应力影响。

案例解析:某海上风电变流器采用6061铝合金散热器(表面阳极氧化处理),在盐雾环境下运行6个月后,氧化层剥落导致接触热阻上升50%,IGBT失效率激增。改用5052铝合金(耐盐雾>1000h)并喷涂聚氨酯三防漆(厚度50μm,符合IEC 60068-2-11标准),3年现场故障率下降75%。

设计要点:

涂层技术:高温场景采用等离子喷涂Al2O3陶瓷涂层(导热系数30W/m·K,耐温>800°C)。

密封结构:IP69K防护等级(双道硅胶密封圈+泄压阀),确保粉尘/水汽零侵入。

误区4:瞬态热负荷建模缺失,相变材料选型不当

典型问题:采用稳态仿真设计散热方案,无法应对毫秒级功率脉冲。

实测数据:某固态功率放大器在5G基站中承受2ms@2000W脉冲负载,传统铝基板方案瞬态温升达55°C,而采用微胶囊相变材料(石蜡/石墨烯复合,相变潜热220J/g)结合瞬态热仿真(ANSYS Icepak瞬态步长1ms),温升控制在18°C,满足MIL-STD-810G冲击测试要求。

动态管理技术:

相变封装:采用蜂窝结构封装相变材料(孔隙率>70%),避免液态泄漏且提升热扩散效率。

模型校准:基于红外热成像(采样率100Hz)修正仿真边界条件,误差<±1.5°C

误区5:TCO评估片面化,忽略隐性运维成本

典型问题:仅对比初期硬件成本,未量化能耗/维护/停机损失。

成本对比:某半导体工厂原采用风冷机柜(初期成本50万元),年电费120万元(PUE=1.8)。升级为两相浸没式液冷后(初期成本180万元),年电费降至45万元(PUE=1.05),且因减少洁净室空调负荷,年综合节支达90万元,2.1年即可收回增量投资(IRR>25%)。

决策模型:

精细化建模:引入蒙特卡洛模拟,量化设备故障率(Weibull分布)对TCO的影响。

政策叠加:结合碳税机制(如欧盟CBAM),液冷系统全生命周期碳排放减少60%,额外获得补贴15%

结语:从经验驱动到数据驱动的热设计范式升级

标准化流程:在概念设计阶段即导入JESD51-14热测试标准,避免后期返工(某光模块项目周期缩短30%)。

多学科协同:通过COMSOL Multiphysics耦合电磁损耗(HFSS提取)与热应变场,某雷达TR组件散热效率提升40%。

智能运维:部署光纤光栅温度传感器(精度±0.1°C)与数字孪生平台,实现故障预测(某超算中心意外停机减少90%)。

通过严谨的工程思维与全链路数据验证,热设计工程师可精准规避“隐形杀手”,为高可靠性系统奠定基础。作为行业实践者,我们致力于提供从材料到系统的闭环解决方案,与客户共同应对热管理挑战。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

1-关键部位的特殊公差要求

在EV电池托盘与储能液冷Pack箱体的制造中,关键连接面与接口的公差控制直接影响密封性、散热效率及装配精度。

a.液冷板安装面

液冷板是电池热管理系统的核心部件,其安装面的平面度直接影响冷却液流道的密封性。若平面度超差,会导致硅胶垫片压缩不均,引发局部泄漏或热阻升高。

b.焊接接缝错边量

电池托盘常采用铝合金焊接结构,焊缝错边会导致应力集中,降低疲劳寿命。尤其对箱体气密性要求高的场景(如IP67),需严控错边。

c.电池模组定位孔

定位孔用于精确固定电池模组,公差过大会导致模组错位,引发电气连接失效或机械振动风险。

d.固定螺栓孔位置度

螺栓孔用于箱体与底盘连接,位置度偏差会导致装配应力,甚至引发螺栓断裂。

e.箱体边缘直线度

箱体边缘直线度影响上下盖装配及IP防护等级,尤其是采用激光焊接的箱体,边缘需作为激光头跟踪基准。

2-尺寸公差对制造效率的影响

尺寸公差对制造效率的影响主要体现在其对加工流程、成本控制及产品质量的平衡上。合理的公差设计既能保证产品功能,又可优化生产节奏。尺寸公差的合理控制对制造效率的影响主要体现在以下几个方面:

a.加工精度与生产成本的平衡

·严格的尺寸公差虽能提升密封性和装配精度,但需采用高精度加工设备和复杂工艺,显著增加设备投入和加工时间。

·过度追求精度可能导致加工成本上升,需在关键功能部位设定严苛公差,非关键区域适当放宽公差以降低成本。

b.返修率与废品率控制

·合理的公差设计可减少因尺寸超差导致的返工。

·焊接变形是电池托盘制造中的主要问题,采用CMT冷焊工艺可优化热输入,减少焊接后变形,缩短返修周期。

c.模组化与标准化生产

·通过标准化组件,公差要求集中于局部可替换部件,降低整体加工难度。

·标准化公差设计还能支持多型号兼容,减少定制化加工需求。

3-平面度控制的行业标准与实际应用

针对新能源汽车电池托盘,行业标准提出严格要求:

a.平面度标准:液冷板安装面平面度需≤0.2mm,底部支撑板平面度≤0.5mm/m²,焊接后框架平面度误差≤0.8mm6。

b.制造工艺优化:采用CNC精铣、CMT冷焊及振动时效处理(VSR),结合激光干涉仪在线检测,降低变形风险。

c.材料选择:推荐使用6061等高强度铝合金,屈服强度≥1180MPa,兼顾轻量化与结构稳定性。

4-材料与工艺驱动的公差调整策略

a.材料创新驱动轻量化

采用轻量化高强铝合金(如6061)及复合材料(碳化硅增强铝基),结合阳极氧化与绝缘涂层,实现减重30%并提升耐腐蚀性,适配液冷系统散热需求。

b.工艺协同提升制造精度

一体挤压成型+搅拌摩擦焊(FSW)减少焊缝数量,CMT冷焊与激光焊接控制热变形。

c.仿真检测闭环保障可靠性

CAE仿真优化加强筋布局,激光扫描与氦检漏技术实现全流程监控,模组化设计兼容±5mm公差,降本增效。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

1-电池托盘/储能Pack箱体铝合金焊接工艺特征

在新能源液冷Pack箱体、电池托盘等产品的制造中,液冷流道与多腔体结构是典型的复杂设计特征(如图1所示)。这类结构往往包含以下特点:

三维空间交错:流道呈蛇形分布,存在大量空间转折点;

多层级连接:主腔体与子腔体通过薄壁隔板连接(厚度2-3mm);

微型化特征:流道截面尺寸小(铝型材流道壁厚最小1.2mm),焊接可达性差。

2-多焊接技术结合在电池托盘制造中的难点分析

在电池托盘制造实践中,需要采用多焊接技术结合,例如搅拌摩擦焊(FSW)、冷金属过渡焊(CMT)、传统熔化焊(TIG/MIG)等技术的协同应用。这种组合旨在兼顾轻量化、强度、密封性及生产效率,但也面临以下核心难点:

a.多工艺热输入协同难题

不同焊接技术(如FSW、激光焊)热输入差异大,易引发材料性能突变与热变形,需通过优化焊接顺序及参数调节解决。

b.设备兼容性与效率瓶颈

设备切换复杂、参数同步精度要求高,需模块化工作站设计与智能焊机提升协同效率,降低节拍时间。

c.密封强度与成本平衡挑战

多焊缝交汇处泄漏风险高(占缺陷70%),需冗余密封+拓扑优化设计。

3-工程实践:电池托盘、储能液冷PACK箱多焊接工艺协同

a. 焊疤位置规划

· 焊接位置优化:在产品设计阶段,应充分考虑焊接位置的合理性,避免焊疤出现在关键部位或影响产品功能的区域。例如,调整前边框与水嘴的间隙,防止焊疤干涉;优化水嘴焊接位置,减少对产品性能的影响。

· 与产品结构的匹配:焊接位置应与产品结构相匹配,确保焊缝能够承受产品在使用过程中的各种载荷和应力。例如,在液冷板项目中,通过合理规划焊接位置,提高了产品的结构稳定性和可靠性。

· 便于操作和检测:焊接位置应便于操作人员进行焊接操作和后续的质量检测。例如,避免在难以到达或视野不佳的位置进行焊接,以提高焊接效率和质量。

b. 焊疤控制

· 焊疤大小:焊疤大小需严格控制,一般要求焊疤高度在4/6mm范围内,且焊疤不超出平面,以保证产品的外观和装配精度。例如,在液冷板项目中,通过调整焊接参数和工艺,成功控制了焊疤大小,避免了焊疤对产品性能和质量的影响。

· 焊疤形状:焊疤形状应尽量规则,避免出现过度熔化或不完全熔合的情况。通过优化焊接参数和操作技巧,可以有效改善焊疤形状,提高焊缝质量。

· 打磨处理:对于摩擦焊位置产生的下凹焊痕,采用打磨处理方式,确保表面平整,满足产品外观和性能要求。

c. 焊接顺序优化

· 分区焊接:对于大型产品,采用分区焊接的方法,可以有效控制整体变形。通过将产品分成若干区域,依次进行焊接,可以减少焊接过程中的热量集中,降低热变形的风险。

· 逐步校正:在焊接过程中,采用逐步校正的方法,及时调整焊接变形。通过在焊接过程中不断测量和校正产品的变形情况,确保最终产品的尺寸精度和形状符合设计要求。

· 优化焊接路径:合理规划焊接路径,避免在同一个区域反复焊接,减少热量输入。例如,在液冷板项目中,通过优化焊接路径,减少了焊接过程中的热量输入,提高了焊接质量。

d. 变形协同控制

液冷板在焊接过程中出现热变形,导致产品尺寸精度下降。

优化措施:

· 采用分区焊接和逐步校正的方法,控制整体变形。

· 优化焊接参数,降低电流和电压,减少热量输入。

· 使用工装夹具固定产品,减少焊接过程中的移动和变形。

· 采用对称焊接的方法,使焊接热量均匀分布。

掌握了FSW/TIG/CMT等关键焊接工艺,那么这些工艺主要服务于哪些具体产品?下文系统解析铝合金在电池托盘、储能Pack及液冷板上的应用全景:铝合金在新能源领域的应用与工艺解析 ——聚焦电池托盘、储能pack及液冷板

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

CTC(Cell-to-Chassis)技术因能显著提升电动汽车续航与空间效率而备受关注,但其能否真正取代传统电池技术仍存争议。制造端的核心瓶颈——电池托盘焊接工艺——成为决定这一技术未来的关键:复杂的结构设计、多元材料兼容性、严苛的热管理需求,让传统焊接技术面临巨大考验。本文从一线工程师视角出发,结合行业动态与工程实践,剖析CTC技术的潜力与局限,并探讨焊接工艺如何成为这场技术革命的“试金石”。

1-CTC技术的“理想与现实”

CTC技术通过将电芯直接集成到底盘,理论上可减少冗余结构件、提升能量密度,但其大规模应用的可行性正面临现实拷问:

车企的激进与谨慎:特斯拉、比亚迪等头部企业已推出CTC方案,但更多厂商仍持观望态度。行业数据显示,截止2025年2月全球CTC量产车型占比15-20%,传统CTP(Cell-to-Pack)技术仍是主流。

续航提升的“代价”:CTC虽能提升15%-20%能量密度,但底盘结构复杂度导致制造成本增加30%-50%(某咨询机构测算),成本与收益的平衡尚未明朗。

维修经济性争议:一体化设计使电池维修成本飙升,保险公司数据显示,CTC车型事故后电池总成更换率高达70%,远高于传统车型的25%。

这些矛盾让CTC技术的未来充满变数,市场端能否突破20%取决于三大变量:特斯拉Cybertruck量产爬坡进度;中国车企价格战是否倒逼CTC降本;欧洲法规对电池可维修性的妥协程度。而制造端的焊接工艺水平,将成为决定其能否跨越实验室与量产鸿沟的关键。

2-焊接工艺的三大“生死关”

对于电池托盘制造商而言,CTC技术落地需攻克三个核心难题:

a.“微米级”精度与效率的博弈

传统焊接工艺可容忍0.5mm误差,但CTC托盘因需承载更多电芯,接缝数量增加3倍以上,且多分布于曲面异形部位。某厂商测试表明,当焊接定位误差超过0.15mm时,电芯组装的良品率会从99%骤降至82%。更棘手的是,精度提升往往伴随效率下降——激光焊精度虽高,但设备成本是传统焊接的5倍以上。

b. 材料混搭的“水火不容”

为兼顾轻量化与强度,CTC托盘常采用“铝合金+碳纤维+特种钢”的混合结构。不同材料的热膨胀系数差异可达20倍(如铝23μm/m·K vs. 碳纤维0.8μm/m·K),焊接时易产生内应力导致开裂。某企业尝试铝-碳纤维连接时,焊缝开裂率一度高达18%,远超行业可接受的3%阈值。

c.热影响区的“隐形杀手”

焊接高温可能损伤电芯周边绝缘材料或传感器线路。某车企曾因焊接热输入控制不当,导致电池模组自放电率增加50%。工程师必须在0.1秒内将焊接温度波动控制在±15℃以内——这相当于在焊枪上装一个“高精度温度刹车”。

3-焊接工艺的三大“生死关”

破局之路:没有银弹,唯有系统创新

面对这些挑战,行业正在探索三条突围路径:

a. 工艺组合的“鸡尾酒疗法”

激光电弧复合焊:结合激光焊精度与电弧焊熔深优势,使铝合金焊接速度提升40%;

冷金属过渡技术(CMT):通过精准热输入控制,将热影响区面积缩小60%;

机器人智能补偿系统:基于实时焊缝扫描数据自动调整焊枪路径,将复杂曲面焊接合格率从75%提升至95%。

b. 材料端的“提前妥协”

部分企业开始与材料供应商联合开发“焊接友好型”复合材料。例如,某国产改性铝合金(通过物理、化学或工艺手段调整后的铝合金材料)的焊接裂纹敏感性从7级降至3级(按ISO标准),虽牺牲了5%的轻量化效果,但使焊接良品率提高至98%。

c.检测维度的“数字孪生”

通过焊接过程全数据采集(电流、温度、速度等),结合AI模型预测缺陷概率。某工厂引入该技术后,焊接缺陷的在线检出率从80%提升至97%,报废成本降低45%。

4-工程师的新命题:在不确定中寻找确定性

a.CTC技术的争议本质上是“系统优化”与“局部极限”的博弈:

若焊接工艺突破速度慢于车企降本预期,CTC可能沦为小众技术;

若材料、工艺、检测技术协同突破,则有望开启电动汽车结构设计的新纪元。

b.对于工程师而言,需从两个维度重构能力:

跨领域知识整合:理解电化学性能对焊接热输入的敏感阈值;

敏捷响应能力:某欧洲供应商案例显示,能在一周内完成新合金材料焊接参数优化的团队,订单获取概率提升3倍。

CTC技术站在了“颠覆性创新”与“量产陷阱”的十字路口。它或许不会完全取代现有技术,但正在倒逼焊接工艺向更高精度、更强兼容性、更智能控制的方向进化。这场技术马拉松中,真正的赢家未必是最早出发的车企,而是那些在制造端把“不可能焊缝”变成“标准化接口”的工程师团队。

探讨了CTC的制造可能性,最终是为了支撑极致的应用需求。当重卡需要600kWh超大电量突破干线物流时,对电池技术提出了哪些终极考验?延伸阅读:新能源重卡“堆电量”破局:600kWh大电量电池如何攻克干线物流市场?

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

随着CTP(Cell to Pack)技术彻底颠覆传统电池包结构,电池托盘的“角色”从被动承载转向主动集成。焊接工艺一跃成为安全与性能的核心命门。轻量化(壁厚仅1.5mm)、零气孔密封、多材料(铝/铜/碳纤维)集成需求,让传统焊接深陷变形与缺陷困局。行业正通过材料革新、智能质检与工艺迭代破局。本文将拆解CTP对焊接的颠覆性挑战,探寻高精度与高可靠性的技术路径。

1-CTP技术对电池托盘结构设计要求的变化分析

CTP(Cell to Pack)技术通过取消传统电池包中的模组结构,直接将电芯集成到电池包中,这一技术革新对电池托盘的结构设计提出了全方位、多维度的升级要求。以下从材料、性能、工艺、集成化等角度展开具体分析:

(1)结构强度与防震性能的全面提升

a.取消模组后的力学承载需求:

CTP技术省去模组结构后,电池托盘需直接承担电芯的支撑、固定及外力缓冲功能。传统模组分散了机械载荷,而CTP托盘需整体吸收充放电过程中电芯的膨胀形变(如方形电芯膨胀力可达10-20kN),同时抵御车辆行驶中的震动、挤压和冲击载荷。

b.材料与结构优化方向

· 高强度铝合金主导:早期钢材因重量大逐渐被替代,6061-T6成为主流,其比强度高、耐腐蚀性强,可满足轻量化与高刚性双重需求。

· 复合结构设计:如零跑汽车的“双骨架环形梁”结构,通过纵横梁隔间增强局部抗冲击性,同时采用挤压工艺优化材料分布,减少冗余重量。

· 镁铝合金与碳纤维探索:镁铝合金比传统铝材减重30%,碳纤维复合材料兼具高强与轻量化特性,但受限于成本与工艺成熟度,目前仅用于高端车型。

(2)气密性与热管理集成要求

a.密封性能升级

取消模组后,电池包内部冷却液循环和气体密封完全依赖托盘,焊接缺陷(如气孔、裂纹)可能导致泄漏风险。

图1-电池托盘气密性检测

b.热管理功能集成

CTP托盘需集成液冷板、导热胶等组件。例如,结构胶用于固定电芯并传递膨胀应力,聚氨酯导热胶(导热系数>1.5 W/m·K)用于电芯间及与液冷管的热传导,单PACK胶黏剂用量较传统结构增加50%以上。托盘内部需设计流道优化冷却效率,同时避免焊接热影响区对密封性的破坏。

(3)轻量化与材料创新

a.材料选择趋势

铝合金挤压与压铸工艺:挤压铝型材用于框架结构(如特斯拉4680电池托盘),压铸工艺(如一体化压铸)简化焊接工序,减重15%-20%。

塑料复合材料应用:例如使用玻纤增强PA6材料,用于非承载部位以进一步减重,但需解决与金属连接界面的兼容性问题。

b.轻量化设计策略

拓扑优化:通过CAE仿真减少冗余材料,在保证强度的前提下降低托盘重量。

薄壁化与集成化:托盘壁厚从3mm降至1.5-2mm,同时集成BMS支架、线束通道等功能部件,减少零件数量。

(4)集成化与模块化设计

a.功能组件的高度集成

CTP托盘需整合电池管理系统(BMS)、高压连接器、防火隔离层等模块。

b.模块化与兼容性设计

焊接产线需要支持多型号托盘混线生产,能够实现“一键换型”,兼容不同电芯尺寸(如方形、圆柱)的托盘结构。

2-CTP技术革新对焊接工艺的具体挑战

CTP(Cell to Pack)技术显著提升了空间利用率和能量密度,但也对焊接工艺提出了前所未有的挑战。

(1)焊接缺陷控制难度激增

a.气孔与密封性挑战

CTP技术取消模组后,电池托盘需直接承担密封功能,焊接气孔(铝合金焊接中常见缺陷)将直接导致冷却液泄漏或气体渗透风险。

b.裂纹与材料兼容性

高锌铝合金(如7系)在焊接时易因热应力产生裂纹。

c.间隙与装配误差

多电芯直接集成导致托盘结构拼接点增加,装配误差累积可能使焊缝间隙超过±1mm。

(2)材料体系升级带来的工艺适配难题

a.轻量化材料的焊接挑战

CTP托盘材料从钢材转向铝合金(6061-T6、7075-T6)、镁铝合金(减重30%)及碳纤维复合材料。铝合金焊接需解决氧化膜难熔、热导率高导致的熔深不足问题。

b.异种材料连接技术

托盘集成液冷板(铜/铝)、防火层(陶瓷基复合材料)等功能组件时,异种材料界面易出现脆性金属间化合物。

(3)结构复杂性与精度要求升级

a.大尺寸薄壁结构变形控制

CTP托盘壁厚从3mm减至1.5-2mm,焊接热变形敏感性激增。

b.高密度焊点与工艺效率

单托盘焊点数量从传统模组的2000个增至5000个以上。

图2-电池托盘焊接

3-生产工艺与质量控制的升级

CTP技术推动电池托盘焊接从“单一工艺”向“多技术协同、智能化、绿色化”转型。制造厂需聚焦三大方向:

技术升级:突破气孔、裂纹等缺陷控制,适配轻量化材料;

智能化跃迁:全流程数字化与AI质检实现高精度生产;

生态协同:联合材料商、设备商、主机厂共建技术标准。

应对了CTP对焊接的挑战后,技术的下一步演进是什么?当集成度更高的CTC成为焦点,焊接工艺将面临何种终极考验?深度解读:CTC技术能否成为下一代主流?焊接工艺成关键胜负手——从制造视角看CTC技术的真实挑战与可能性

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

在通往百亿亿次(Exascale)AI算力的道路上,华为的CloudMatrix 384超节点与NVIDIA的GB200 NVL72集群,已成为全球瞩目的两座技术高峰。它们不仅代表着不同的硬件集成能力,更深刻地揭示了两种构建超级计算系统的根本性哲学。

一个被比喻为“持续高烧”,面对的是384颗芯片稳态运行下、密不透风的极限散热挑战;另一个则被形容为“间歇性癫痫”,需要驯服72颗顶级GPU同步工作时产生的剧烈脉冲热流。这两种不同的“病因”,最终指向了截然不同的“药方”——即散热解决方案,并为我们清晰地展现了两种核心工程哲学:确定性系统工程与敏捷性生态创新的对决。对于身处其中的每一家供应链企业,理解这场对决,是定义自身未来角色的关键。

1-核心差异的根源——“病因”决定“药方”

在设计起点上,华为与NVIDIA就走向了不同的道路,这直接塑造了它们迥异的热源特性:

表1:两种技术路线热源特性对比

这种“持续高烧”与“间歇性癫痫”的差异,绝非偶然。它反映了华为作为挑战者,选择以系统总性能为核心进行攻坚,不惜代价在单机柜内实现算力密度的极限突破;而NVIDIA作为领导者,其任务是在保证单芯绝对性能优势的同时,构建一个能高效协同并易于普及的生态系统。

2-工程哲学的物化——两种液冷路径

两种不同的设计哲学,在关键的液冷方案上得到了最集中的体现,塑造了从芯片到机房的完整技术栈。

a. 华为:确定性系统工程的液冷实践

这是一种自上而下、为系统级确定性目标而生的设计哲学。其核心是将散热作为基础设施的关键部分进行全局一体化、高可靠性的工程实现,而不仅仅是配套部件。

图1:华为昇腾 384 超节点

· 芯片级精工与可靠连接:为确保芯片热量高效传递至冷板,华为聚焦于界面材料的工程优化。虽然公开资料显示其在该领域(如高球形度碳化硅填料)有前沿专利储备,但其在超节点中的具体应用方案并未公开。可以确定的是,其方案必然追求极低的界面热阻和长期可靠性,以应对“持续高烧”的挑战。

· 系统级冗余与智能控制:采用如环形供液等冗余设计,并自研液冷热管理控制器(TMU) 作为系统“中枢”。该控制器能实现管路间0秒切换,并通过AI进行故障预测,以软件定义的方式保障散热链路的确定性与可靠性,这是其系统工程思维的典型体现。

· 基础设施融合(“冷电融合”):在机柜层面,将液冷分配单元与高压配电单元进行物理集成与统一管理。这种“冷电一体”的设计,是应对单柜超高功率密度、简化部署和提升能效(降低PUE)的终极工程响应,是其确定性设计从理念到物理形态的落地。

b.NVIDIA:敏捷性生态创新的液冷框架

这是一种以GPU为核心、通过定义开放标准赋能全球生态的设计哲学。其核心是提供一套经过验证的“蓝图”,降低全行业的应用门槛,实现高效、灵活的规模化部署。

· 芯片级标准化与参考设计(VRD):NVIDIA为GPU(如Blackwell系列)提供详细的散热参考设计,明确定义冷板的物理尺寸、热设计功耗(TDP)、流量与压降等性能接口。这等于为所有散热厂商提供了“标准答案”,将复杂性封装在标准件内,确保了基础组件的兼容性和质量基线。

· 生态级协作与方案认证:与Vertiv、Boyd等顶级热管理及基础设施厂商深度合作,共同开发并认证机柜级液冷解决方案。例如,Vertiv的 Tier 2 Ready 机柜方案就是基于NVIDIA蓝图开发的预验证产品,使数据中心运营商能够像采购标准设备一样,快速获得即插即用的液冷集群。

· 数字孪生赋能与部署加速:通过NVIDIA Omniverse平台,提供数据中心液冷系统的数字孪生和仿真工具。客户可以在虚拟环境中对散热方案进行设计、验证和优化,极大降低了实体验证的成本与风险,实现了从设计到部署的敏捷化。

为了更清晰地理解这两种路径,我们将其核心差异对比如下:

表2:华为模式 vs. 英伟达模式:关键差异一览

3-历史的启示与未来的融合

这两种路径的竞争,在科技史上并非孤例。它本质上是系统整合式创新与平台生态式创新的又一次经典演绎。华为像当年的乔布斯时代的苹果,追求对产品体验从顶层到底层的绝对掌控;而NVIDIA则更像如今的谷歌Android,通过制定核心标准(Android系统/GPU架构)来驱动整个生态的繁荣。

对于行业而言,未来的趋势并非一方彻底取代另一方,而是可能出现一定程度的融合:

· 在追求极致算力的国家或企业级项目中,“确定性系统工程”的魅力依旧不减。

· 在广阔的商业化云计算市场,“敏捷性生态创新”将因其速度和成本优势持续扩张。

· 智慧的火花可能诞生在交叉地带:在开放的生态标准中,融入更深度的定制化与协同优化。

4-结语

因此,华为与NVIDIA的散热之争,本质是AI时代两种核心竞争力的对垒:一方追求通过系统工程的深度整合,实现确定性的极致性能;另一方则通过构建开放标准与生态,驱动产业的敏捷创新与快速普及。这场对决为产业链上的参与者划出了清晰的路径选择:是作为“特种部队”,深入绑定,攻克具体的系统级堡垒;还是作为“主力军团”,融入生态,在广阔的标准平原上开拓市场。最终,胜负不仅在于技术本身,更在于对产业演进逻辑的洞察,以及对自身在未来蓝图中位置的明确定位。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

当电芯的“大”成为共识,Pack的“强”成为新战场

储能行业正迎来电芯容量跃升的时代,从280Ah迈向500Ah+已成为进行中的现实。当行业聚焦于电芯的“大”时,Pack的“强”——即其机械结构承载与安全化解能力——正成为新的竞争焦点。无论电芯化学体系与容量如何演进,其膨胀力、热失控能量与机械载荷,最终都需由Pack下箱体这一机械基础来承担。

本文将从结构设计的角度,探讨在电芯技术路线分化的背景下,Pack下箱体如何应对差异化的机械与热管理需求,并构建可持续适配的工程能力。

1-三大技术路径的机械解析:载荷、热与空间的三角难题

电芯容量的提升,直接改变了Pack系统设计的边界条件。下箱体作为系统的“骨架”与“皮肤”,需要重新回答三个基础问题:

a. 对587Ah(高集成路径)的力学解析

核心诉求:在标准20尺集装箱内实现≥6MWh的能量密度,催生了“共4列8簇”等极致紧凑布局。

下箱体挑战:

· 结构承载优化:在整体质量增大而支撑点减少的情况下,箱体需优化传力路径,兼顾整体刚度与关键区域的局部强度,以保障运输与运行中的结构稳定。

· 热管理结构融合:液冷系统与箱体底板及支撑结构深度集成,既作为热管理核心,也参与整体承力。设计需确保在长期结构载荷与热循环下,冷却密封的持久可靠。

储能Pack下箱体仿真

· 空间精确协调:箱体须在有限空间内为电芯膨胀、电气连接热位移及消防管路等预留合理间隙,实现各子系统在紧凑布局下的可靠共存。

b.对684Ah(超大容量路径)的热力与结构对应分析

核心诉求:通过单电芯容量最大化来降低单Wh成本,但带来了物理层面的集中化效应。

下箱体挑战:

· 膨胀力的“焦点”效应:单个电芯的膨胀力与容量并非线性关系,而是接近指数级增长。箱体内部框架需设计更强大、更均匀的“束缚系统”,将集中的膨胀应力分散至整个箱体,避免局部塑性变形。

· 热管理的“均匀性”困境:更大的发热体需要更高效的导热路径。下箱体的底板材质、厚度、与电芯底部的接触界面设计(如导热垫的压缩率设定)变得至关重要。热失控时,更大的能量释放对泄压通道的定向导流能力和内部防火隔断的阻燃时效提出了更高要求。

· 重量集中的结构响应:更重的单电芯改变了Pack整体的振动模态,下箱体需重新进行疲劳仿真,防止在特定频率下发生共振导致的连接件松动或结构开裂。

c.对392Ah(稳健过渡路径)的制造适配说明

核心诉求:侧重于在性能、成本与交付效率之间取得平衡,为市场提供经过充分验证的解决方案。

下箱体挑战:

· 成熟方案的稳定实现:基于已验证的设计与工艺体系,通过严格的制程控制确保产品一致性,支撑快速、稳定的量产节奏.

· 供应链的深度协同:依托成熟的供应体系,通过材料选型、工艺优化与规模化采购,持续提升产品的综合成本竞争力。

2- 应对分化的工程思维:

面对多条技术路线,下箱体供应商无法为每条路径重建技术体系。真正的解决方案在于平台化的精准响应——以可扩展的模块化设计,高效适配不同需求。

a. 聚焦共性的物理原理与协作模式

电芯迭代遵循稳定的物理规律。我们基于核心参数建立协同评估流程,结合材料与结构数据,快速研判新电芯可行性,早期识别匹配风险,帮助收敛设计方向,减少后期反复。

587Ah储能Pack下箱体

b.构建“标准接口 + 可配置模块”的弹性体系

为应对技术路线分化带来的定制化需求,我们建立了清晰的接口标准化与内部模块可配置的设计体系:

· 统一对外接口:箱体与储能集装箱的安装定位、电气贯穿接口、冷却系统对接点等,均严格遵循行业常见规格,确保系统层面的兼容性与装配一致性。

· 可配置内部结构:我们提供系列化的内部支撑组件与热管理集成方案,可根据电芯尺寸与排布方式灵活组合。

· 热管理集成模块:热管理模块采用模块化设计,以优化温升控制与电芯均温性为核心,可灵活适配不同技术路线的热管理需求。

c.推行“制造即设计”的柔性产线

为匹配技术路线的多样化,我们的制造体系围绕可扩展的基础平台与模块化装配进行组织:

· 基础箱体平台制造:确保主体结构的精度与一致性,为不同配置提供可靠载体。

· 模块化装配单元:支持根据电芯尺寸与排布方式,灵活选用相应的内部支撑与热管理模块进行装配。通过这种布局,我们能够在同一产线上高效完成不同技术路线产品的生产切换,协助客户应对多路线并行开发带来的供应链与交付挑战。

3-下箱体价值的重新定义:从被动承载到主动赋能

下箱体正从被动容器转向系统关键赋能部件,直接影响安全、能量密度与全生命周期成本:

a.安全承载结构:通过为系统级泄压与防火隔断提供可靠的结构通道与安装基础,与热蔓延控制共同构建多级安全防护。

b.能量密度支撑:轻量化、高强度设计减少自身重量与空间占用,为电芯与冷却系统留出更多性能余量。

c.长期可靠性保障:结构完整性与疲劳耐久设计,支撑系统应对长期循环、运输振动等持续挑战。

4-结论:在分化的上游与确定的下游之间,构筑桥梁

随着电芯技术演进,储能系统持续追求安全、高密度与低成本。下箱体需提供可靠且适配的支撑基础,以模块化及柔性制造应对不同技术路线。行业竞争正转向系统级工程,Pack箱体是其中的关键一环。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

在数据中心发展的数十年间,风冷技术始终是主流选择。然而,英伟达GB200系列产品的推出,正将这个平衡彻底打破。当计算密度达到新的高度,传统的散热方式已无法满足需求,液冷技术正式从幕后走向台前,成为支撑AI算力的关键基础设施。

1-需求端的根本性转变

a.功率密度突破临界点

GB200 NVL72机柜的功率密度预计将达到30kW/柜以上,这个数字远超传统风冷技术15-20kW的散热极限。这意味着:

· 技术路线的必然选择:液冷从“值得考虑”变为“唯一选择”

· 市场空间的质变:每个GB200部署都意味着确定的液冷需求

· 价值量的大幅提升:单个机柜的液冷系统价值达到数十万元级别

b.可靠性要求升级

随着单机柜算力密度的提升,其承载的业务价值也呈指数级增长。液冷系统的可靠性直接关系到:

· 业务连续性:一次散热故障可能导致数百万的算力损失

· 系统寿命:温度每升高10℃,电子元件寿命减半

· 性能稳定性:散热效率直接影响芯片能否持续维持峰值性能

2-技术要求的全面提升

a.散热效率的阶跃需求

GB200对散热系统提出了前所未有的要求:

· 导热性能倍增

· 冷板导热系数需要达到传统方案的3-5倍

· 接触热阻要求降低一个数量级

b.流量精度控制

· 需要实现±1%以内的流量控制精度

· 支持动态流量调节,适应不同负载工况

c.温度均匀性

· 芯片表面温差需控制在5℃以内

· 避免局部热点影响系统稳定性

3-系统集成复杂度的跃升

液冷系统已从简单的部件供应,发展为复杂的系统工程:

a.传统模式:

· 提供标准化冷板

· 简单的管路连接

· 基础监控功能

b.GB200时代:

· 机柜级液冷架构设计

· 智能流量分配系统

· 实时健康状态监测

· 预测性维护能力

图2-英伟达GB200机柜

4-竞争壁垒的全面提升

在新的市场环境下,企业需要跨越更高的门槛:

a.技术壁垒

液冷企业必须突破单一学科的限制,构建跨领域的综合技术体系。微通道设计、材料科学与流体力学等多学科技术的深度融合成为基础门槛,而芯片级的热仿真与优化能力更是考验着企业的深层技术积累。这已不再是简单的工艺改进,而是需要长期研发投入的系统性工程。

b.认证壁垒

行业认证体系正变得日益严苛。企业不仅要通过服务器厂商制定的严格可靠性测试,还要获得芯片原厂的技术认证。这种双重认证要求不仅验证产品的技术性能,更考验企业的质量体系和持续稳定供货能力,成为进入核心供应链的必备通行证。

c.服务壁垒

随着液冷系统升级为核心子系统,服务能力已成为关键竞争要素。企业需要建立覆盖全国的快速响应网络,并构建7×24小时的专业运维体系。这种服务能力不仅要求技术支持的及时性,更需要预防性维护和应急处理的全流程服务解决方案,真正成为客户可信赖的合作伙伴。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

在计算架构的演进史上,某些时刻的到来并非悄无声息。英伟达GB200 NVL72的推出,就是这样一个时刻——它不仅仅是一款新产品,更是一次对服务器概念的彻底重构。

三十年来,“服务器”始终意味着一个标准化的机箱单元:内部是主板、CPU、内存、硬盘和扩展卡,通过行业标准接口互联。我们以“U”为单位衡量它,在机柜中堆叠它,通过网络连接它。然而,GB200 NVL72的出现,正将这一稳固的定义从核心处瓦解。

它的本质不再是“一台服务器”,而是一台以整个机柜为形态的“计算机”。传统的服务器组件被解构,然后在更大的尺度上,通过NVLink-C2C、液冷散热和机柜级供电管理,被重新集成为一个不可分割的计算整体。这不再是简单的升级,而是一场深刻的范式转移。

1-什么是“服务器”?这个问题的答案正在改变

三十年来,我们理解的服务器是一个标准化的机箱:里面有主板、CPU、内存、硬盘、扩展卡,所有组件遵循着行业标准,可以随意替换和升级。

但GB200的改变是根本性的:

· 计算核心不再是独立的CPU和GPU,而是GB200超级芯片——一个将CPU和GPU深度集成的整体

· 互联不再依赖标准的PCIe插槽,而是定制化的NVLink背板

· 散热不再是可选配件,而是集成的液冷系统

· 基本的部署单元从“机箱”变成了“机柜”

传统服务器的各个组件被“撕碎”,然后在机柜这个更大的尺度上重新整合。这不是进化,而是重构。

表1-物理架构的重塑:从“机箱”到“机柜”

2-“机柜级体系架构”的三大支柱

传统的服务器设计,是在一个封闭的机箱内进行平衡与妥协。而GB200代表的机柜级体系架构,则是在一个全新的维度上,将散热、互联、供电与管理视为一个完整的系统进行顶层设计。这不再是组件的堆叠,而是系统级的深度融合。其背后,依赖于三大核心支柱的协同创新。

支柱一:从“网络互联”到“背板总线”

在传统数据中心中,服务器是独立的节点,通过网络(如以太网)进行通信。而在GB200 NVL72中,机柜内部的NVLink Fabric在角色上已经取代了传统主板上的总线,成为连接所有计算单元的“骨架”。这种改变使得机柜内的72个GPU能够像一个巨型GPU一样协同工作,通信带宽和延迟得到了数量级的优化。

支柱二:散热从“配套设施”升级为“核心子系统”

当计算密度从每机柜数十千瓦迈向上百千瓦时,传统的风冷技术已无计可施。液冷不再是一个可选的“配套设施”,而是成为了与计算、互联并列的核心子系统。其设计直接决定了整个系统的性能释放与运行稳定性,是从“可用”到“高效能”的关键。

支柱三:管理与供电的“集中化与重构”

GB200采用了机柜级的集中供电与管理。这不仅是追求电源转换效率的提升,更是对系统耦合度的重新定义。它带来了更简化的布线和统一的管理视图,但也将故障域从单个服务器扩大至整个机柜,对运维提出了全新的范式要求。

3-价值链的重构与转移

GB200所代表的“机柜级体系架构”,其影响力早已超越技术本身,正清晰地勾勒出一条新的行业价值链曲线。传统的价值分布正在被打破,新的价值高地则在系统级集成与软硬件协同处悄然形成。

服务器厂商:从“定义者”到“集成者”的战略转型

传统的服务器巨头,如戴尔、HPE,正面临其核心价值的迁移。它们曾经赖以生存的能力——主板设计、系统优化与标准化生产——在GB200这样的高度定制化、出厂即一体的系统中,其重要性正在下降。

然而,危机之中蕴藏着新的战略机遇:

· 价值上移:竞争焦点从服务器内部设计,转向机柜级的液冷散热、供电效率与结构布局。

· 价值外延:核心竞争力从硬件制造,延伸至大规模部署的专业服务、跨平台运维管理以及与企业IT环境的整合能力。

这意味着,服务器厂商的角色正从一个标准产品的“定义者”,转型为复杂系统的“高级集成与赋能者”。

云厂商的“战略性采购”:在依赖与自主间寻求平衡

对于超大规模云厂商(Hyperscaler)而言,GB200既是战略必需品,也是战略警示。

· 短期战术:作为算力的终极标杆,采购GB200是满足市场对顶尖AI算力需求的必然选择。

· 长期战略:为防止供应链风险与技术锁定,自研AI芯片(如TPU, Trainium, Inferentia)已成为关乎未来自主权的核心战略。

云厂商的行为,生动体现了在效率与自主、短期市场与长期控制之间的复杂权衡。

终端用户的决策演变:从评估“组件”到考量“产出”

对于最终用户的技术决策者(CTO、技术VP)而言,采购的评估范式正在发生根本转变。

传统的采购清单:

· CPU的核心数与主频

· GPU的型号与数量

· 内存与存储的容量和速率

如今的战略考量:

· 效率指标:每瓦特性能、模型训练总时长

· 总体拥有成本:包含硬件、能耗、运维与人力在内的综合成本

· 业务敏捷度:从部署到产出的时间周期

这种转变,标志着企业技术采购从成本中心思维,向生产力投资思维的关键演进。

GB200重新定义了计算单元——从“服务器”到“机柜”。这不仅是性能升级,更是架构范式的彻底转变。效率的追求超越了组件堆砌,行业价值链正在重构。在这场变革中,唯一确定的是:适应它,或是被它抛下。

新的计算纪元已经开启。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

当您的设备拥有多个核心发热点,且它们彼此独立、功耗各异或需隔离冷却时,此时再用传统的单流道液冷板便力不从心了,而多回路型嵌铜管水冷板正是您破局的关键。

1-为何选择多回路?三大场景直击痛点

a.隔离热干扰,保障核心单元性能

当IGBT与二极管、CPU与GPU等不同器件密集排布时,单一流道会导致热量相互“串扰”,使低温器件被迫在高温下运行。多回路设计如同为每个器件配备了“专属空调”,彻底杜绝热干扰,确保每个单元均在最佳温度区间工作,从而提升整体系统性能与稳定性。

b.实现系统冗余,打造高可靠性架构

在对可靠性要求极高的领域(如服务器、通信基站),单一冷却回路的失效意味着系统宕机。多回路设计可构建 “N+1”冗余冷却系统。当一条回路意外失效时,其余回路仍能提供基础散热能力,为系统维护争取宝贵时间,是实现高可用性设计的基石。

c.应对异形布局与差异化散热需求

面对不规则排布的热源,单一流道难以实现均匀散热。多回路支持 “量体裁衣” ,您可以根据热源的实际形状和布局,灵活定制每一根铜管的走向,用最优的流道路径精准覆盖每一个发热点。同时,可为高功耗器件配置大流量回路,为低功耗器件配置小流量回路,实现散热资源的最优分配。

图1:多回路嵌铜管液冷板

2-设计与制造的核心:如何在方寸之间平衡性能与可靠?

在多回路设计中,流道间距是决定成败的关键。

a.热学底线:防止“热短路”

相邻流道间距若过小,即使流道独立,热量也会通过中间的铝基板快速传导,使隔离效果大打折扣。我们通过仿真与测试,确立了 ≥1.5倍管径 的基础间距原则,确保热独立性。

b.结构红线:守住“承压生命线”

流道间的铝基板是承受内压的薄弱环节。间距过窄会导致肋板强度不足,在压力冲击下有撕裂风险。我们通过机械应力仿真,确保在任何工况下,流道间的应力都远低于材料的屈服极限,从根本上杜绝“爆板”隐患。

图2:嵌铜管液冷板

c.工艺极限:保障“精密制造”

狭窄的间距对铣槽刀具是巨大考验。我们基于丰富的制造经验,将间距与刀具直径关联,确保在高效加工的同时,获得光滑平整的槽壁,为后续铜管的紧密嵌套和低热阻结合奠定基础。

3- 工程实现要点

成功的多回路设计需要把握以下要点:

a.协同设计

建议在概念阶段就介入热设计和机械设计,综合考虑流道布局、结构强度和工艺能力,避免后续设计变更。

b.工艺控制

• 采用高精度CNC铣槽,确保槽宽公差与表面质量

• 使用带芯棒弯管技术,保证铜管弯曲后的通畅性与壁厚均匀性

• 可靠的嵌套固定工艺,防止铜管在振动工况下移位

验证测试

c.完善的测试体系包括:

• 100%气密性测试

• 流量-压降特性测试

• 热阻性能验证

• 爆破压力测试

总结而言, 多回路嵌铜管水冷板是解决复杂多热源散热问题的利器。成功的关键在于深刻理解其设计逻辑,并在性能与可靠性间找到最佳平衡点。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

1-铜管预处理(折弯与压扁)

目标:将直的圆铜管,塑造成与设计流道完全一致的扁平形状。

a. 材料选择:为何是无氧铜?

无氧铜(C1220)纯度高达99.9%,无晶界氧化物,使其像面团一样延展性极佳,在折弯和压扁时不易开裂或产生微裂纹,保证后续可靠性。

b. 折弯半径:安全底线

最小弯曲半径 ≥ 1.5倍管径是铁律。小于此值,铜管外侧壁会被过度拉伸而减薄甚至破裂。使用芯棒弯管机是防止内侧起皱的关键。

c. 压扁:精密的“减肥”

压扁不是简单压扁,而是通过精密模具进行可控的塑性变形。压扁后的流道高度不得小于原始内径的30%。核心目标是保证压扁后壁厚均匀,不能出现局部死褶或过度减薄,否则此处就是未来的泄漏点。

图一:热管弯折

d. 工序抉择:先折弯还是先压扁?

必须“先折弯,后压扁”。对圆管进行弯曲是成熟可控的工艺;若先压扁,扁管几乎无法进行小半径高质量弯曲,且流道内壁会严重变形,流阻激增。

2-基板加工(精密铣槽)

目标:在铝基板上加工出用于嵌套铜管的、尺寸精确的“轨道”。

图二:嵌入式铜管

a. 槽宽设计:过盈配合

槽宽必须设计得略小于压扁铜管的宽度(通常小0.05-0.1mm),形成 “过盈配合” 。这能靠摩擦力紧紧“抱住”铜管,是实现初步固定和降低接触热阻的基础。

b. 槽深控制:飞切余量

槽深决定了铜管嵌入后凸出基板表面的高度,这个高度就是后续飞切工艺的加工余量。槽深一致性直接影响最终铜管剩余壁厚的均匀性。

c. 刀具与“刀颤”

加工窄而深的槽时,铣刀长径比过大易发生“颤振”,导致槽壁粗糙、尺寸超差。因此,流道间距不能过小,必须给刀具强度和刚度留出空间。

d. 清洁度:隐形的质量

铣槽后,铝屑和油污必须100%清除。任何残留物都会在铜管和铝基板之间形成隔热层,大幅增加接触热阻,使散热性能大幅下降。

3-嵌套与固定

目标:将成型铜管精准嵌入基板凹槽,并形成稳固的结合。

a. 过盈配合:主固定力

依靠精确的尺寸设计,通过压机外力将铜管“挤”进稍窄的槽中。材料自身的弹性回复力会产生巨大的正压力,这是最主要的固定力来源。

图三:热管固定

b. 辅助固定:防“跷跷板”

仅靠过盈配合,铜管端头在热应力下可能翘起。需辅助固定:微点焊(强度高,需控热)或高导热环氧树脂(应力小,有老化风险)。

c. 界面热阻的敌人

铜管与铝槽之间的空气是热的不良导体,是界面热阻的主要来源。高导热胶或焊接能填充微观空隙,取代空气,显著降低热阻。

d. 电化学腐蚀预警

铝和铜在电解质中会形成原电池,铝作为阳极会被腐蚀。必须确保冷却系统的密封性和使用去离子水/防腐冷却液,从系统层面切断腐蚀路径。

4-表面成型(飞切 vs. 深埋)

目标:形成最终可用于安装芯片的、具有高平面度和低热阻的散热表面。

a. 飞切工艺:性能王者

使用超硬刀具同时切削铜和铝,形成共面齐平的完美表面。这使得热源能与导热性极佳的铜管直接、大面积接触,实现最低热阻。

b. 深埋管工艺:可靠卫士

将圆铜管嵌入并填充高导热环氧树脂。铜管保持圆形,承压能力更强,填料提供了额外的保护和应力缓冲,可靠性更高,但热阻稍大于飞切。

c. 最终壁厚:生命线

飞切工艺的核心控制目标是铜管的最终剩余壁厚。它必须在性能(薄) 和可靠性/防切穿(厚) 之间取得平衡,通常控制在 0.15-0.3mm 的黄金区间。

d. 平面度:接触的保障

无论哪种工艺,安装面的平面度(通常要求<0.1mm) 都是硬性指标。微米级的起伏都需用导热硅脂填充,平面度差会导致接触热阻飙升,散热失败。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

为提升电动汽车续航与容量,动力电池包正从单层布局转向多层堆叠结构。这一转变显著提高了能量密度,也带来了全新的结构挑战。本文将从核心难题、主流方案和未来技术方向三个方面展开探讨。

1-核心挑战:多层堆叠的力学难题

将动力电池包从单层扩展至多层,远非简单叠加。它重塑了内部的力学环境和外部的载荷路径,带来四大核心挑战:

a.垂直方向载荷激增与材料蠕变风险

·多层结构中,电芯、模组及结构件的重量会逐层累积。底层承受的静态压缩载荷远高于顶层。

·这种持续高压应力对材料的长期性能构成严峻考验,特别是抗蠕变性能(材料在恒定应力下随时间的缓慢塑性变形)。

·若层间支撑或电芯固定部件发生蠕变,会导致预紧力松弛,影响电芯循环寿命和界面接触稳定性。因此,寻找兼具轻量化和优异抗蠕变特性的材料至关重要。

b.膨胀力叠加效应与结构稳定性

·锂离子电池在充放电时,因电极材料体积变化会产生“呼吸效应”,导致电芯膨胀。在多层堆叠结构中,膨胀力逐层累积,使底层模组承受巨大压力。

·这种周期性应力易引发箱体鼓胀变形、密封失效、结构件挤压电芯导致短路,以及加速电池性能衰减。有效控制需依靠内置传感器实时监测结合数字仿真,从而指导结构优化设计。

c.空间利用与能量密度的核心矛盾

·应对重力和膨胀力需要加强结构(如增加横梁、加厚板材),但这会占用宝贵空间并增加重量,与提升体积能量密度和重量能量密度的核心目标冲突。

·解决之道在于结构优化和高效材料应用,这推动了电池包向多材料混合设计的转变。

d.碰撞载荷传递路径与安全冗余升级

·动力电池包高度增加,加剧了侧碰或底碰时的力学负荷;其增高结构放大了杠杆效应,对连接点强度和电池包自身刚度提出了更高要求。

·需采用抗冲击材料与一体化设计以优化传力与吸能,保障极端工况下电芯安全,进而推动电池-车身一体化(CTC)技术发展,使电池包成为车身结构的重要组成部分。

2- 主流结构方案对比分析

为应对挑战,业界探索了多种创新方案:

a.一体式压铸托盘(One-piece Die-cast Tray)

·优势: 集成度高,减少零件数量,提升整体刚度、一致性和密封性。工艺支持复杂几何形状,便于集成冷却、加强筋和安装点。整体结构利于管理复杂应力。

·挑战: 整体压铸多层框架对设备、模具和工艺要求极高,成本昂贵。碰撞后修复困难或不可行。整体刚性结构可能缺乏管理层间差异膨胀力的灵活性。

b.多级框架模块化(Multi-level Frame Modular)

·优势: 设计制造灵活,便于生产、维护和更换。天然适合多材料混合设计,可针对不同层级优化性能和成本。借鉴复合材料“准各向同性叠层”理念优化整体力学响应,分散应力。

·挑战: 零部件和连接件多,装配复杂,累积公差影响精度和预紧力。大量连接界面(螺栓、铆钉)是潜在失效点并增加重量。

c.混合材料夹层结构(Hybrid Material Sandwich Structure)

·优势: 卓越的轻量化效率和极高的比刚度(高强度面板+轻质芯材如泡沫/蜂窝铝)。强大抗弯性能,芯材兼具隔热和吸能特性,提升热安全和碰撞安全。符合多功能集成趋势。

·挑战: 制造工艺复杂,成本高。面板与芯材的界面结合强度和长期耐久性是关键。芯材需具备优异的抗压蠕变性能。

d.仿生蜂窝结构

·优势: 理论上是实现极致轻量化、高刚度和抗压强度的理想仿生设计(模仿蜂巢六边形)。提供均匀支撑,冲击吸能能力强。

·挑战: 制造极其复杂且成本高,与冷却系统等集成难度大。目前更多处于前沿研究阶段,大规模商业化应用仍需时日。

3-关键技术突破方向

未来解决多层堆叠设计难题的关键突破在于:

a.轻量化与刚度平衡的材料与工艺革新

·材料: 持续优化CFRP、铝合金、镁合金;开发兼具低蠕变、高绝缘、良好导热、易加工的新型多功能聚合物及复合材料。

·工艺: 发展先进连接技术(电阻点焊、激光焊、超声波焊)实现可靠、轻量的多材料连接。

图1:电池托盘机器人激光焊

b. 膨胀力自适应管理

思路从“刚性对抗”转向“柔性适应”,创造动态响应系统,使电芯在生命周期内处于最佳应力环境。

c.层间连接与一体化革命

·连接技术: 由螺栓机械连接向结构胶粘接与先进焊接演进,以实现更均匀的应力分布、良好密封和抗疲劳性能。

·终极集成: CTC/CTB(Cell-to-Chassis/Body)是未来电池包一体化的重要方向。通过取消独立外壳,将电芯或模组直接集成于底盘,使多层堆叠本身成为车身结构件(如横梁或地板),从根本上解决空间限制,最大化电池结构功能。实现该技术需电池、结构、热管理和安全等多领域深度协同,是“结构即功能”理念的终极形态。

图2:动力电池包电池托盘

多层堆叠是提升电池能量密度的必然选择,却也带来了结构、膨胀力与安全的巨大挑战。破局之道在于材料创新、仿生结构优化和膨胀力智能管理。最终,电池包将与车身深度融合,成为一体化的“能源底盘”。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

电动重卡两大核心挑战:电池布局与电池堆叠技术深度解析

当一辆满载货物的电动重卡行驶在高速公路上,支撑它跨越数百公里的核心秘密,就隐藏在车辆的底盘与电池舱内。在重卡电动化浪潮席卷全球物流业的今天,电池系统的布局与堆叠技术已成为决定市场胜负的关键。

图1:电动重卡电池液冷方案

电池布局:三大方案如何重塑电动重卡形态?

a.背式布局:短途运输的敏捷之选

·场景适配: 港口、矿山、钢厂等封闭场景的短途运输

·核心优势: 极速换电能力(具体时间需实测验证),提升车辆出勤率

·性能局限: 电池容量受限(行业普遍<350kWh),高重心影响高速稳定性

·空间代价: 占用货舱或驾驶室空间,降低载货能力

b.底盘式布局:长途干线的续航王者

·电量突破: 电池容量可突破500kWh(如行业公开的513kWh方案)

·空间魔术: 底盘空间高效利用,避免货舱侵占

·安全加成: 超低重心设计提升高速稳定性

·技术门槛: 底盘一体化开发,防护与热管理要求更高

c.底侧边式布局:换电网络的效率引擎

·换电革命: 侧向换电提升操作效率

·空间平衡: 保留完整货舱,续航能力介于背式与底盘式之间

·安全攻坚: 需强化侧撞防护结构

2-堆叠技术:重卡电池包的高效集成方案

多层堆叠技术正成为提升能量密度的关键路径:

图2:堆叠式重卡液冷集成箱

a.无框架一体堆叠技术:

·电芯直接堆叠,减少结构件

·取消模组与框架,电芯直接“Z向无缝堆叠”

·显著提升系统能量密度

·支持超快充技术(具体性能需实测验证)

b.模组到底盘集成(如MTB/CTC技术)

·MTB技术:模组直连车架,体积利用率显著提升

·麒麟电池(CTP 3.0):72%体积利用率,255Wh/kg能量密度

·CTC技术:电芯融入底盘结构,减重10%

c.电芯形态创新(如刀片电池)

·扁平电芯紧密排列,体积利用率提升(比亚迪公开数据>50%)

·突破磷酸铁锂能量密度瓶颈

3-电动重卡的核心技术挑战

挑战1:结构安全

·极端工况: 侧柱碰撞对侧边布局构成致命威胁

·创新方案:高强铝合金壳体+缓冲结构;碰撞仿真优化(FEA);超国标机械冲击测试。

挑战2:热管理

·热失控警报: 包内温差控制至关重要

·技术突破:液冷板侧向冷却(温差<3℃);冷媒直冷技术;模型预测控制(MPC)动态调控。

挑战3:振动疲劳

·隐藏杀手: 道路振动导致结构损伤

·应对策略:Z向堆叠优化应力分布;路谱振动台架测试;高阻尼材料应用。

4-三大趋势引领当下发展

·底盘式布局主导中长途干线:高续航(>500kWh)与低重心特性成为首选

·CTC技术深度集成:电池与底盘结构融合,提升空间利用率和系统刚性

·智能化热管理普及:AI算法实现精准温控(温差<5℃),延长电池寿命

·固态电池技术演进:半固态电池加速商业化,潜力集中在安全性与能量密度提升

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

电动重卡的浪潮正席卷全球物流运输业,为“双碳”目标注入强劲动力。然而,伴随续航里程需求飙升而来的,是单包容量普遍突破500kWh甚至迈向1000kWh的超大电池系统。这如同在车上装载了一个移动的“能量堡垒”,其潜在的热安全风险也达到了前所未有的量级。当“超大容量”、“极速热蔓延”(<2分钟)、“超高抗撞”(>1500kJ)三大极端安全指标叠加,行业面临严峻的技术鸿沟。本文剖析这些挑战,并探讨构建电动重卡专属安全防线的系统化解决方案。

图1:短刀三层堆叠方案

1-500kWh+时代:机遇与安全挑战并存

a.容量跃升已成主流,为满足重载长途需求,电动重卡电池包已从200-300kWh快速跃升至600kWh+。巨头纷纷推出500kWh、600kWh乃至1000kWh级别的解决方案,标志着超大容量时代正式到来。

b.LFP(磷酸铁锂)电池技术的成熟是重要推手,其在安全性和循环寿命上的优势使其成为重卡主流选择。

2-极致安全下的“三大挑战”

a.热蔓延极限控制(<2分钟):

·核心目标: 安全设计必须延迟或阻断热蔓延,为人员逃生和救援创造时间窗口(如国标GB 38031-2020要求的5分钟预警)。

·严峻现实: 500kWh+高密度电池包内,单个电芯热失控释放的巨大能量极易引发灾难性链式反应。实测数据显示热蔓延速度极快:有案例22秒席卷全舱,5秒引燃相邻模组,模组间传播最短仅约44秒。

·核心难点与缺口: 如何有效确保模组间热蔓延被控制在2分钟以上? 目前尚无商用重卡系统公开承诺并验证能满足此严苛指标。

b.结构抗撞高墙(>1500kJ):

·核心需求: 满载重卡碰撞能量远超乘用车,轻松大于1500kJ,作为底盘结构件的电池包必须具备超高强度,碰撞后保持完整,防止内部电芯损伤引发热失控。

·严峻现实: 现行国内外标准(如GB/T 31467.3-2015, UNECE R100)对重卡电池包的碰撞能量测试阈值定义不清或偏低。公开的、通过1500kJ级别碰撞测试的认证数据极其缺乏。虽有更高能量仿真研究(如2500kJ),但完整系统验证仍是巨大挑战。

·核心难点与缺口: 缺乏明确的高能量碰撞防护标准及经过充分验证的解决方案。

c.二次灾害连锁风险(货物爆炸 & 道路瘫痪):

·货物爆炸风险: 电池热失控的高温火焰极易引燃货舱货物(尤其危化品),形成 “电池失控→货舱起火→货物爆炸”的灾难链。

·道路瘫痪风险: 锂电池火灾扑救困难(需大量持续冷却水)、易复燃。数十吨重卡在公路/隧道起火,救援复杂(高压断电、防毒气)、耗时长(可达数小时,影响或持续24小时),极易造成严重交通瘫痪,社会影响巨大。

·核心难点与缺口: 缺乏针对性的量化道路清障时效标准和高效应急处置体系。

3-构筑防线:热事件预警系统设计:四重防护网

4-热管理配套方案:为预警系统赋能

液冷系统:集成高效液冷板,消除局部热点,维持电芯间温差<3℃。

模块化设计:独立可拆卸模组结构,支持故障单元快速更换。

智能监控平台:云端实时分析电池健康状态,预警信息自动推送至运维团队。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

在新能源重卡市场,“堆电量”正成为关键词:主流车型电池容量突破370kWh,600kWh以上车型密集亮相。这不仅是技术参数的跃升,更是行业对干线物流市场的攻坚宣言——通过提升单次续航能力,解决用户核心痛点“里程焦虑”,并优化全生命周期成本(TCO)。本文将拆解背后的商业逻辑与技术破局路径。

1-商业逻辑:为什么必须“堆电量”?

a.场景驱动的刚需

·封闭场景(短途高频):港口、矿山等场景依赖换电模式(3-5分钟补能),280kWh电池可满足需求。

·干线物流(长途运输):占货运总量70%,需单次续航500公里以上。600kWh+电池成为打开市场的“敲门砖”。

b.TCO的经济博弈

关键结论:日均行驶超300公里时,换电重卡TCO开始优于燃油车。

b.模式创新:化解成本之困

·电池租赁(BaaS):用户购“裸车”,电池月租(5000-9000元),初始成本降低30%。

·换电服务:度电服务费0.2-0.5元,综合能源成本约2.73元/公里(接近燃油车2.8元)。

·商业验证:换电站日服务50车次,投资回收期可缩至5年(IRR达13.1%)。

2-技术破局:如何平衡续航与自重?

a.空间布局的妥协:底盘换空间

·为避免电池挤占货仓,行业正优化电池布局。例如,将电池集成在车辆底盘内(取代传统的背挂式),释放货箱空间、降低重心并可能改善能耗。

·代价: 这牺牲了部分离地间隙和底盘设计的通用性。

b材料科学的妥协:能量密度换重量

·减轻车重的根本在于提升电池能量密度(单位重量存储更多电量)。更高的能量密度能让电池更轻,或在相同重量下跑得更远。

·核心是电池材料创新(如高镍正极、硅碳负极)。

·代价: 能量密度的提升往往伴随安全性风险、寿命缩短、成本增加和快充能力下降等问题,需要在多个性能间艰难权衡。

c.商业模式的妥协:网络换单车压力

·新能源重卡换电模式巧妙地将无限续航的压力从单车转移到了换电网络上。通过在干线沿途密集设站,车辆只需携带足够到达下一站的电量,无需背负跑全程的巨大电池。

·效果: 这降低了对单车电池容量的极端要求,使电池装载量更趋“合理”。

d.残值管理:BaaS的核心壁垒

电池银行需构建全生命周期能力:健康度(SOH)监控、 梯次利用、 回收体系。

图1:重卡电池pack箱

3-未来趋势:从“堆电量”到“高效载电”

a.技术迭代:固态电池将突破能量密度瓶颈,重塑自重与续航平衡。

b.补能网络:重卡换电标准统一与电网协同(如调峰)是规模化关键。

c.多路线竞争:氢能重卡在长途重载领域仍具替代潜力。

阶段性策略,长期性进化:

“堆电量”是电动重卡攻坚干线物流的必然选择,其本质是商业场景需求与技术现实间的动态平衡。随着电池技术跃迁和商业模式成熟,行业将从“电量竞赛”转向“效率竞赛”。而当下,它正推动中国新能源重卡完成从“小众”到“主流”的关键一跃。

我们会定期更新有关热设计与轻量化的技术与资讯,与您分享,供您参考,感谢您对迈泰的关注。

重型卡车(重卡)作为公路物流的核心运力,其动力电池系统的安全性、可靠性与经济性成为技术焦点。电池托盘作为承载、保护和管理电池模组的关键结构件,正面临着前所未有的极限挑战。

图1:电动重卡电池托盘

1-重卡托盘的极限挑战

a.严苛的机械耐久性要求:振动、冲击与百万公里寿命

重卡设计寿命 ≥150 万公里,是乘用车的 10 倍以上。电池托盘必须在这一“全生命周期”内,持续承受以下三类极端机械载荷:

·高频随机振动:满载通过非铺装、施工或坑洼道路时,底盘会在 5 Hz–2 kHz 的宽频带内产生随机振动。这些振动不仅考验托盘主框架的疲劳极限,更在焊缝、螺栓孔、翻边等应力集中区诱发微裂纹,成为失效起点。

·高 g 瞬时冲击,路面深坑、紧急制动或装卸跌落可在毫秒级内产生 50 g 以上的冲击加速度。托盘需在瞬间吸收/分散能量,防止电芯发生位移、短路或壳体破裂。

·累积疲劳破坏,百万公里意味着上亿次振动循环。铝合金在交变应力下易产生疲劳裂纹并扩展,最终导致结构断裂。设计的核心任务是通过拓扑优化、局部加强、异种材料混合及工艺控制,将裂纹萌生寿命推迟至整车退役之后。

b.复杂的热管理与热循环挑战

重卡电池包因超大容量(数百kWh)与高功率充放电产生巨量热量,且运行环境横跨寒带至热带,面临极端温差。

·宽温域控制:托盘及热管理系统须在-40℃至+85℃ 环境温度下,将电芯温度精准维持在25-40℃最佳区间,且单体温差<5℃;

· 强应力循环:实验室加速老化测试中,需承受数千次 -40℃↔85℃ 剧烈温变循环(速率5-15℃/min,极值驻留5-15分钟)。此过程引发材料(铝合金/密封胶/塑料件)界面反复热胀冷缩,对集成冷却管路的焊接/胶接点可靠性构成严峻考验。

2-主流材料方案与多功能集成技术

为应对上述挑战,行业在材料选择和设计理念上形成了以高强铝合金为基础,向多功能高度集成演进的技术路线。

a.核心材料选择:6xxx系铝合金的统治地位

在与钢、镁合金及复合材料的竞争中,6xxx系(Al-Mg-Si)铝合金凭借其优异的综合性能、成熟的加工工艺和较高的性价比,已成为重卡电池托盘的“主流”材料。

主要牌号及性能:

· 6061-T6:这是应用最广泛的牌号,以其卓越的强度、良好的可焊性和抗腐蚀性著称。

· 6005A-T6 和 6063-T6:作为补充选择,同样具备良好的挤出性能,适用于对强度要求稍低的部件。

b.设计理念转型:热管理与结构健康监测

现代重卡电池托盘的设计理念已发生根本性转变,不再局限于提供物理支撑的“承载体”,而是进化为高度集成的“智能温控平台”。这一趋势主要体现在两大技术方向上:

· 高效热管理集成(成熟应用),这是目前技术最成熟、应用最广泛的集成领域。核心思路是将冷却功能直接融入托盘的结构设计中,实现高效且紧凑的热管理。