目标并竭力推动您的项目效益提升

电动汽车发展正面临结构性瓶颈。电池包已不仅是容器,更需成为整车的核心结构体。我们深知行业痛点:

能量密度困境 - 有限空间如何承载更多能量?

热管理压力 - 快充带来的高热如何有效控制?

安全可靠性 - 如何确保全生命周期内抵御碰撞、振动等挑战?

我们以结构与功能一体化集成破局。通过将电池包的承载、散热、防护功能深度融合,打造更高能量密度、更安全可靠、更高效生产的结构系统。让电池包从“容纳单元”进化为“功能核心”,为电动车发展提供坚实基础。

电动乘用车

聚焦续航里程与用户体验,我们提供高度集成的CTP方案。通过极致轻量化设计与高效热管理,助力打破续航焦虑,支持快充需求,让每一度电都能发挥最大价值。

电动商用车

专注全生命周期可靠性,我们打造堡垒式结构方案。强化托盘设计,优化热管理系统,确保车辆在高强度运营下的安全耐用,为您的商业运营提供值得信赖的保障。

我们以专业解决方案,让每种车型都能获得最适合的电池包结构系统。

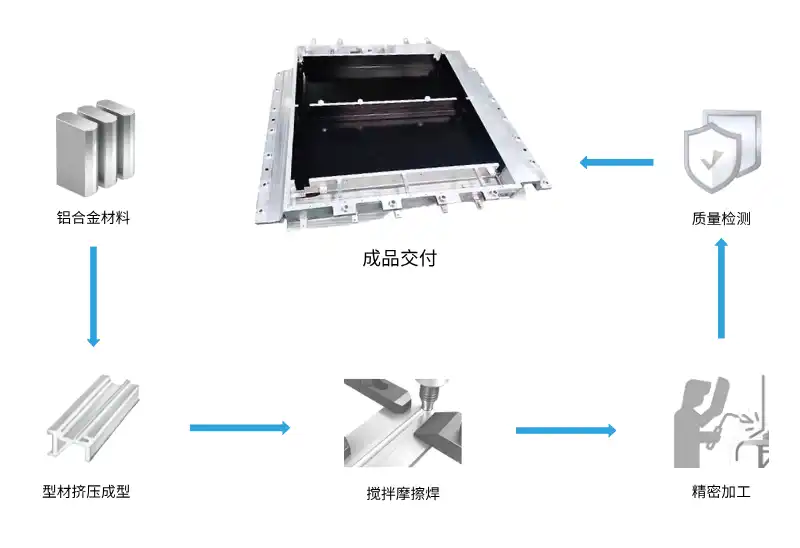

我们掌握大型铝型材一体挤压成型技术,实现结构与功能的深度融合。

集成化流道设计

通过精密挤压工艺,实现底板与冷却流道的整体成型。这种一体化结构确保了流道的完整性与连续性,为热管理系统提供稳定可靠的运行基础。

优异的结构性能

一体成型的基体具备完整的金属流线,展现出良好的结构强度与刚性。同时,精确成型的流道为冷却液提供了均匀流畅的通道,保障了系统的散热效率。

我们在关键连接部位采用搅拌摩擦焊工艺,确保核心结构的连接质量。

可靠的密封性能

该工艺通过材料的塑性流动形成致密均匀的焊缝,能够实现高性能的密封效果,满足严苛的防护等级要求。

稳定的连接质量

搅拌摩擦焊形成的焊缝具有优良的力学性能,接头强度高,缺陷率低。同时,其低热输入的工艺特性有助于控制焊接变形,保证产品尺寸精度。

这两项核心工艺相互配合,共同构成了我们产品高质量与高可靠性的技术基础。