Aluminum Processing Team

Can be manufactured around

the clock, 7 days a week.

Can be manufactured around

the clock, 7 days a week.

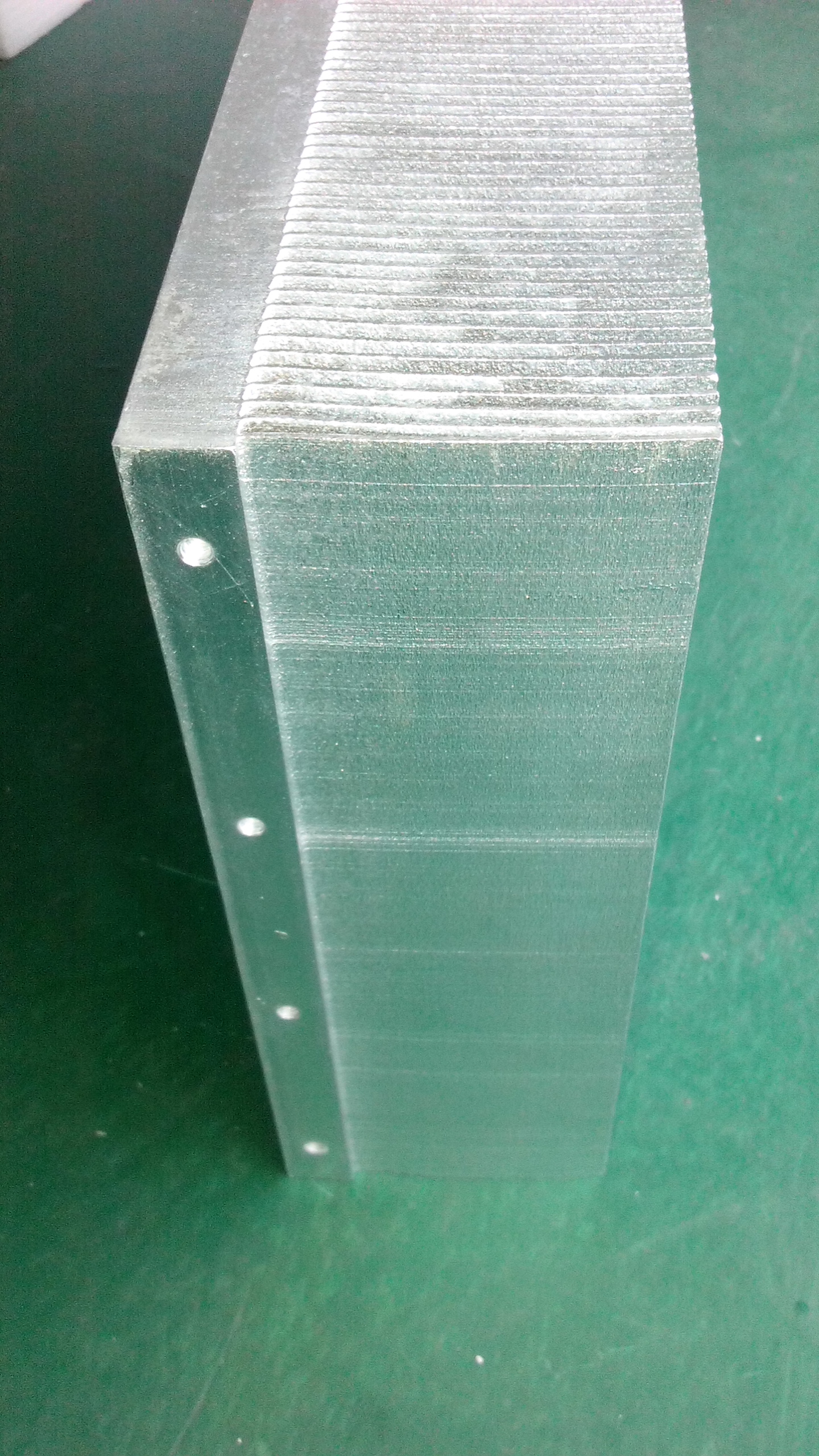

Type

Skived Fin Heat sink

Process

Skiving

Extra Process

Skiving+CNC Machining

Material

AL1060、AL 6061、AL6063、Cu1100、Cu1020

Size/Color

customized

Surface treatment

Sandblasting, Wire Drawing, Painting, Electroplating, Anodizing

Quality Control

full inspection

Application

Automobile、Inverter、Communication

OEM

Accept

Key points of profile heat sinks design

ü Fin design considerations:

Overall consideration should be given to heat exchange area, wind speed, heat exchange efficiency, Fin sheets that are too thin are prone to deformation, while those that are too dense can affect heat dissipation.

ü Determine the size of the heat sink based on usage and heat dissipation needs. The internal flow channels of the radiator should be as simple as possible to ensure smooth flow of the cooling medium.