Communication and sharing promote growth

Joining Hands for Development!

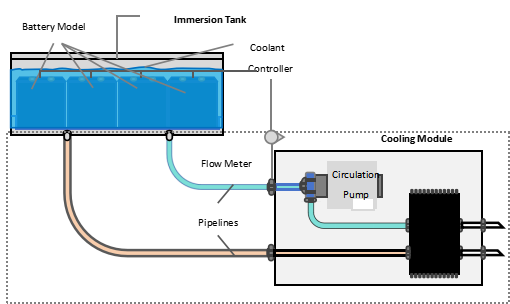

Energy storage immersion liquid cooling technology is an advanced battery cooling method that uses the efficient thermal conductivity of liquid to achieve rapid, direct and sufficient cooling of the battery, ensuring that the battery operates in a safe and efficient environment. Its basic principle is to completely immerse the energy storage battery in an insulating, non-toxic liquid with heat dissipation capabilities. This technology uses direct contact between the liquid and the battery for heat exchange, thereby quickly absorbing the heat generated by the battery during charging and discharging, and bringing it to the external circulation system for cooling.

Schematic diagram of the principle of a single-phase immersion liquid-cooled energy storage system

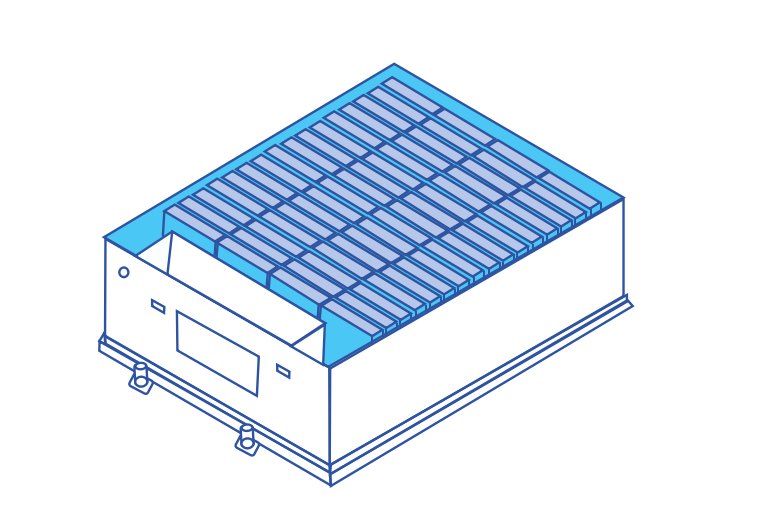

As a key component for carrying the battery pack and ensuring that the battery cells work in a suitable environment, the immersion liquid-cooled energy storage Pack box mainly undertakes functions such as carrying the battery pack and coolant, safety protection, and heat conduction. Therefore, in the design of the box structure, it is necessary to comprehensively consider multiple aspects such as airtightness, cooling efficiency, safety, material selection, and processing technology to ensure efficient, safe, and reliable operation of the system. The box structure design is the basis of the entire liquid cooling system.

1-Unified load

The lower box of the immersion liquid cooling energy storage pack is composed of a bottom plate and side plates. The bottom plate serves as the basic support, while the side plates are fixed around the bottom plate, together forming the main frame of the box. The size of the box is adjusted based on the overall needs and load conditions of the liquid cooling system. In the design of a larger box, an internal partition or process structure can be reasonably set to divide the large space into multiple small spaces, and the uniform load capacity can be improved by increasing the force-bearing area. The internal structure can increase the local load-bearing capacity by adding support ribs and reinforcing ribs, and a load-balancing structure can be set inside the box to balance the load in each corner.

At the same time, in order to reduce the impact of plastic deformation on uniform load-bearing, the processing surfaces of different heights can be designed as the same plane, which can reduce the number of machine tool adjustments and avoid deformation caused by height differences; the width or height of the box can also be increased to disperse the load and reduce deformation.

In addition, the integrated design of the liquid cooling channel and the bottom plate of the box is completed by stir friction welding or laser welding. This design can effectively improve the overall structural strength.

Schematic diagram of the lower box structure of a single-phase immersion liquid-cooled energy storage pack

2-Heat exchange design

Thermal conductivity is an important part of immersion liquid cooling energy storage technology. The design goal is to ensure that the battery can effectively dissipate heat in a high temperature environment, thereby maintaining its performance and safety.

The material of the box should have high thermal conductivity. Commonly used materials are aluminum alloy, copper, and aluminum-based composite materials. The box design also needs to consider the impact of ambient temperature changes. The appropriate thickness of the insulation layer can ensure that the temperature inside the box is within a relatively constant range, thereby improving the overall efficiency of the system.

The structural design of the box directly affects its thermal conductivity. Reasonable flow channel layout ensures that the liquid flows smoothly inside the box and maximizes the contact area, which is the main strategy to improve the thermal conductivity of the box. Multiple flow channels can be set inside the box to increase the coolant circulation path, thereby improving the heat dissipation effect.

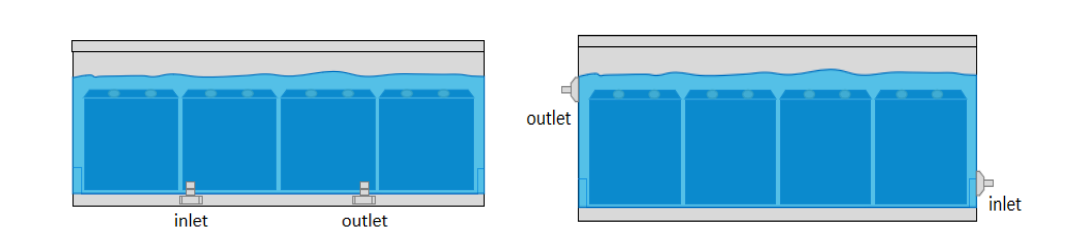

Solution 1: single item + plate replacement Solution 2: single item + box replacement

The liquid cooling system includes a cooling medium, a heat-conducting structure, a liquid cooling pipeline and a supporting structure.

In the first scheme, the same or different types of coolants can be selected to be filled into the liquid cooling plate flow channel cavity and the box cavity respectively, and the two cavities are sealed and not connected to each other. In the box cavity, the coolant immerses the battery module, fully contacts it, cools it without flowing, and absorbs the heat on the battery surface by using the good thermal conductivity of the liquid to reduce the temperature rise. In the liquid cooling plate, the coolant is divided into multiple flow channels in the water inlet manifold and enters the cold plate in parallel, and then converges and flows out in the water outlet manifold, which is mainly responsible for taking out the heat and achieving heat dissipation.

In the second scheme, the coolant with low temperature flows in from the bottom or side, and the coolant with high temperature flows out from the top. The coolant circulates in the battery pack, which can effectively and evenly distribute the heat, improve the overall cooling efficiency, and maintain the consistency of the temperature of the battery cell or battery pack.

In order to further improve the cooling effect, a variety of optimization measures can be taken, such as optimizing the liquid flow and circulation method, selecting a coolant with high heat capacity, and improving the temperature distribution of the liquid. These measures reduce heat buildup and energy loss, ensuring the battery operates in an efficiently cooled state.

3-Sealed design

For liquid cooling pack boxes, the fully sealed design is carried out by adopting advanced sealing materials and structures. The sealing design should not only consider air tightness, but also the sealing of liquid media to ensure that the battery cells are leak-free in all directions.

The design should select the appropriate sealing form and shape according to the specific application requirements, and also consider factors such as the leakage freedom, wear resistance, medium and temperature compatibility, and low friction of the seal, and select the appropriate seal type and material according to the detailed specifications.

In addition, the choice of welding process also has a great influence on the sealing performance. For different materials and thicknesses, choosing the appropriate welding method can effectively improve the quality of the weld to ensure the overall strength and sealing of the system.

Finished picture of the lower box of the single-phase immersion liquid-cooled energy storage pack

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference.

Thank you for your attention to Walmate.