Aluminum Processing Team

Can be manufactured around

the clock, 7 days a week.

Can be manufactured around

the clock, 7 days a week.

Type

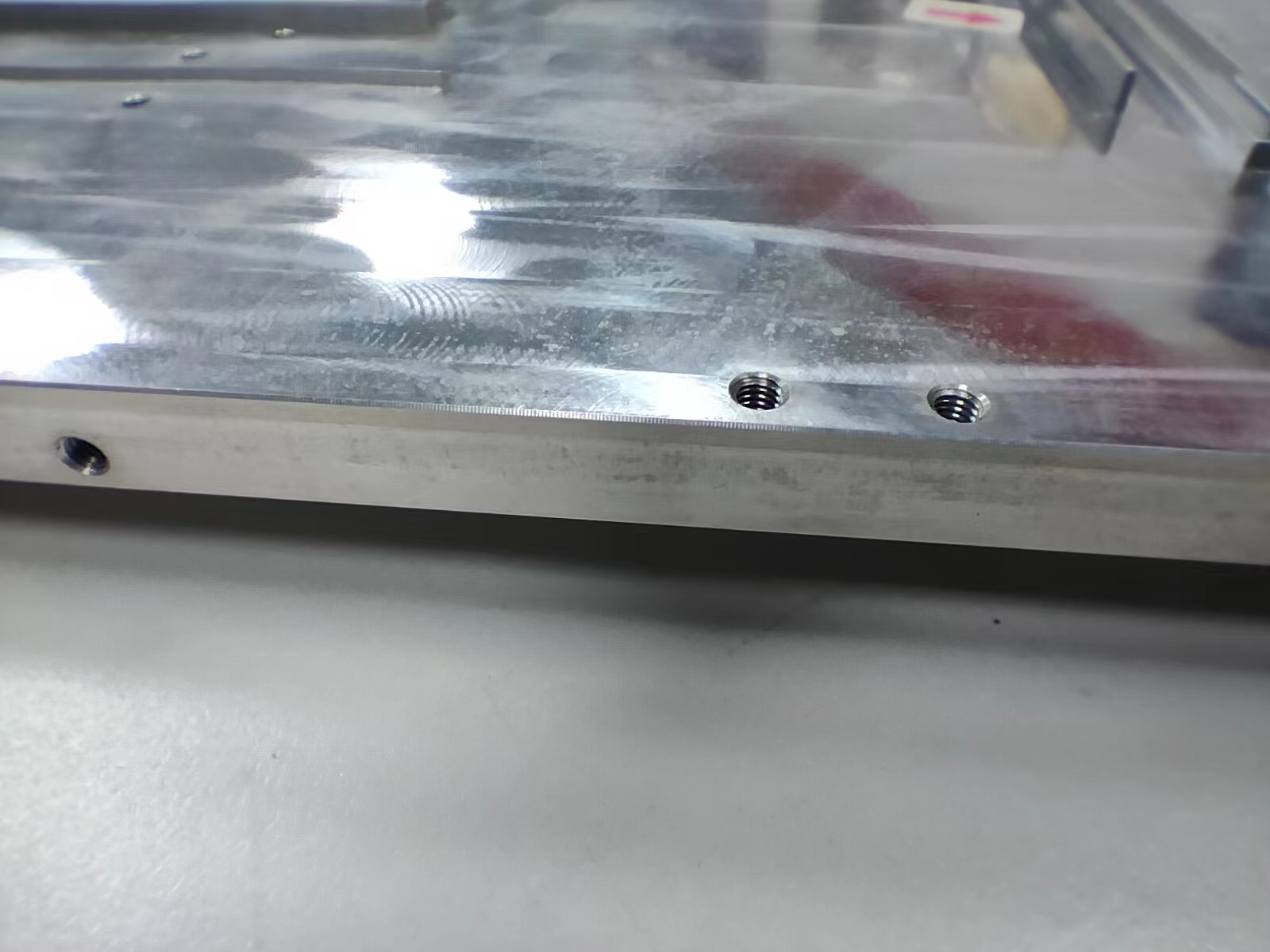

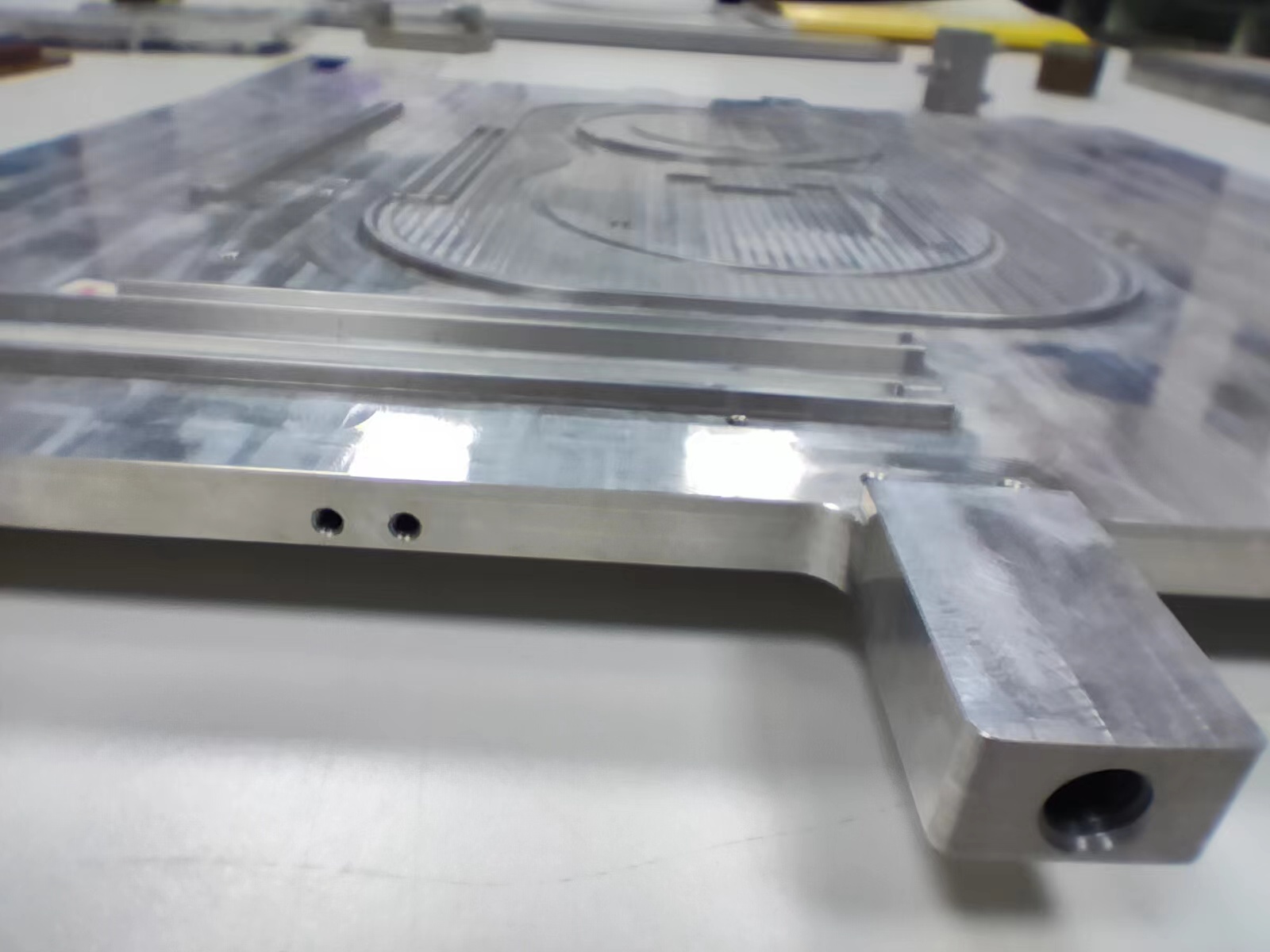

Brazing cold plate

Process

Brazing

Extra Process

Stamping/Skiving+CNC Machining

Material

Al1060、Al3003、 Al4045、Cu1100、Cu1020

Size

customized

Quality Control

full inspection

Application

New Energy Vehicle、Energy storage、Supercomputing

OEM

Accept

Key points of Brazed Cold Plate design

1、Flow channel design: Design the cold plate flow channel structure based on manufacturing process, product conditions, thermal resistance distribution, and other factors, including the size of the cold plate, flow channel structure, and inlet and outlet positions.

2、Material selection: Suitable welding and lining materials should be selected according to the actual situation. When selecting welding materials, factors such as their chemical composition, mechanical properties, and corrosion resistance should be considered to ensure the quality and stability of the welded joint.