Aluminum Processing Team

Can be manufactured around

the clock, 7 days a week.

Can be manufactured around

the clock, 7 days a week.

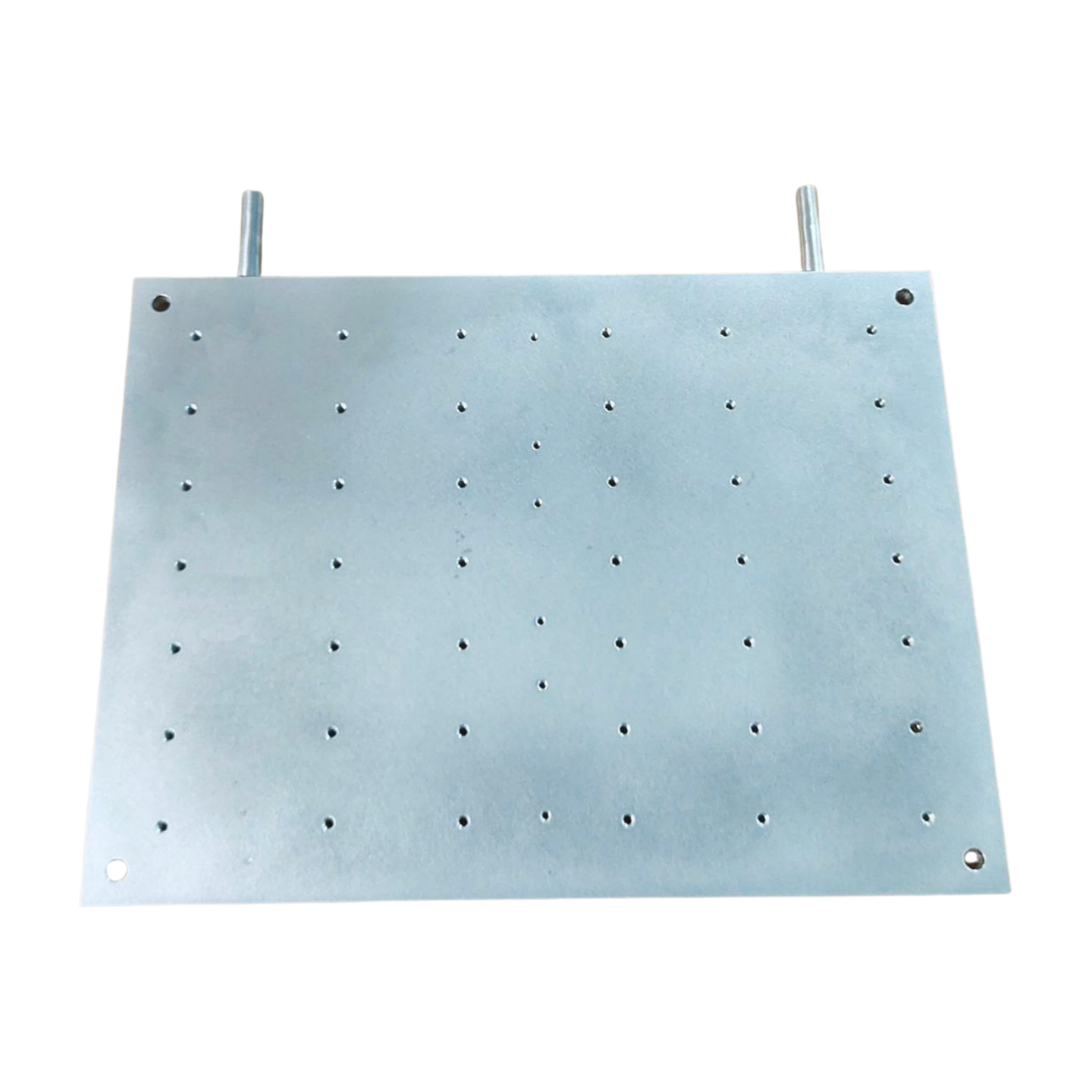

Type

Heatpipe Assembly Heat sink

Process

Bending/Flattening/Brazing

Extra Process

Extrusion/Skiving+CNC Machining

Material

Al1060、 Al 6061、Al6063、Cu1100、Cu1020

Size/Color

customized

Surface treatment

Sandblasting, Wire Drawing, Painting, Electroplating, Anodizing

Quality Control

full inspection

Application

Mechanical Equipment、Source、Electronic Devices

OEM

Accept

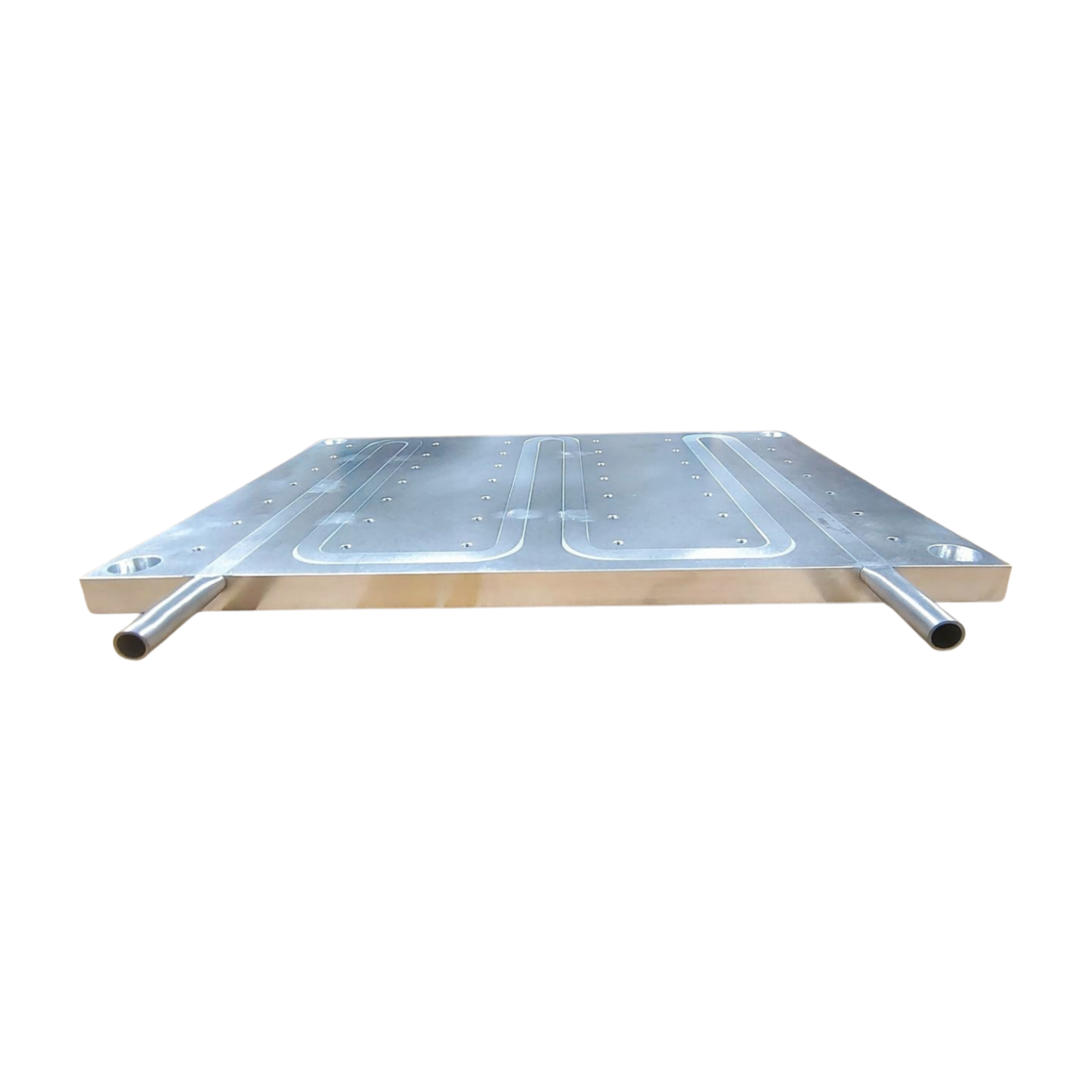

Key points of profile Tube Cold Plate

ü Material of substrate: Try to avoid having two metals with significant electrode potential differences in a system to reduce electrochemical corrosion.

ü Structure of cold plate types: Based on the structure of the liquid cooling system and whether it bears weight.

ü Design of flow rate: Due to the large size of the water-cooled system, simulation analysis of the entire system is generally not conducted. Instead, the flow rate of the water-cooled radiator is set first, and then the water pump is matched based on the corresponding system flow resistance. After determining the total heat and physical properties of the working fluid, the flow rate and temperature rise are inversely proportional.