Communication and sharing promote growth

Joining Hands for Development!

As the core equipment of the energy storage system, the energy storage converter is an important tool for power conversion, energy management, ensuring grid stability, improving energy efficiency, etc. As the energy storage converter power unit moves toward high integration and high efficiency, the development of frequency and large capacity puts higher and higher requirements on heat dissipation.

1-Changes in cooling requirements

a.Matching the larger DC cabin, the converter capacity continues to increase, and efficient heat dissipation technology ensures the reliability of the equipment.

As the capacity of energy storage cells becomes larger and larger, the capacity of energy storage systems is also expanding simultaneously. At the beginning of 2023, the standard 20-foot single-cell battery capacity on the market was only 3.35MWh. In the second half of the year, many battery cell companies have launched 310+Ah energy storage products, and the capacity of the 20-foot single-cell battery has also been expanded to 5MWh. However, less than half a year after the 5MWh model was updated, some leading energy storage systems released 6MWh and 8MWh systems. According to general experience, the energy storage converter is configured at 1.2 times the load capacity. The single unit capacity of a 5MWh energy storage system must be greater than 2.5MW. High power requires more efficient cooling technology to ensure stable operation of the equipment under sustained high loads.

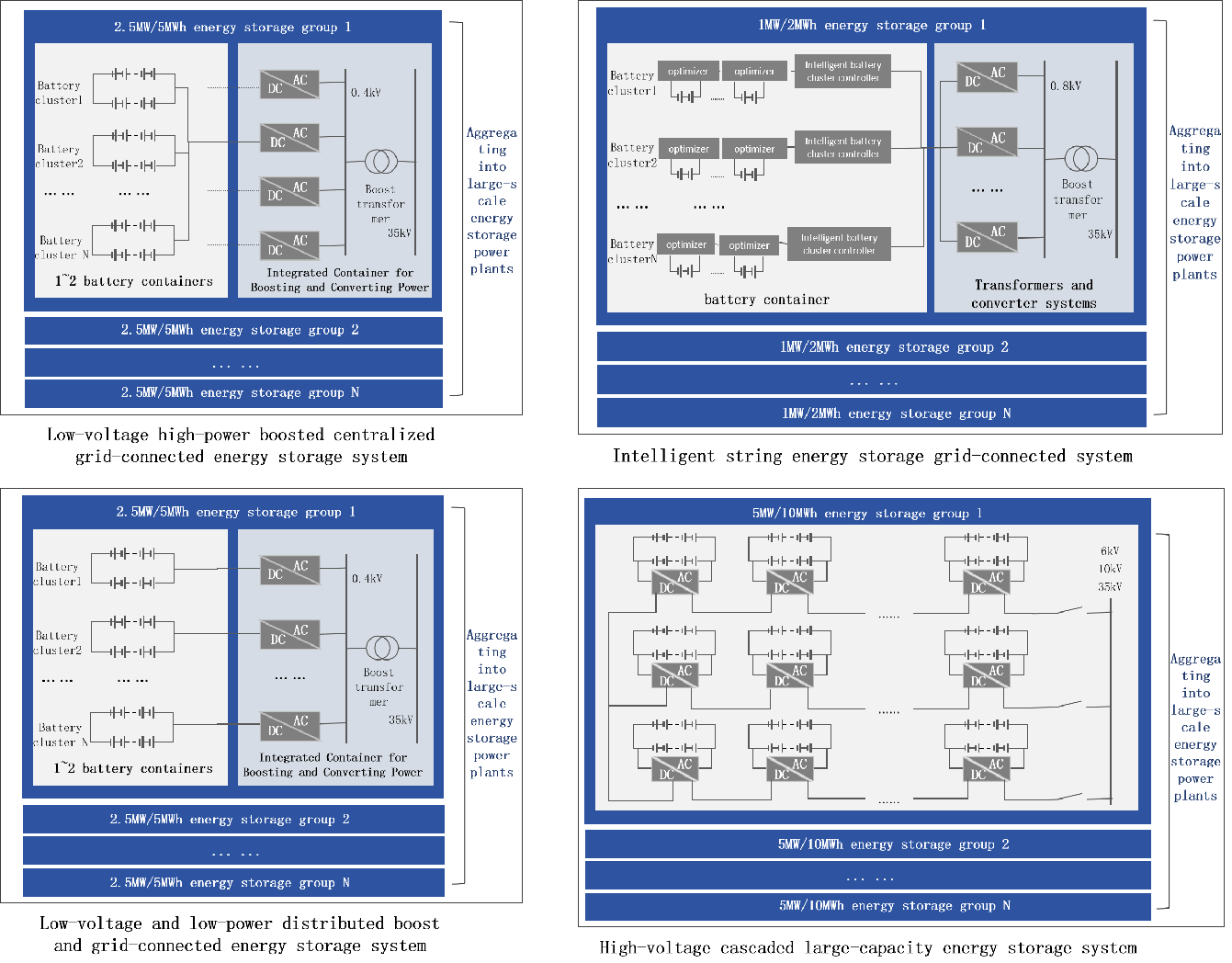

Iterative evolution of energy storage system integration topology scheme

b.The application of DC high-voltage technology requires devices to have higher withstand voltage levels and insulation strength, and the heat dissipation of power devices is severe.

In order to match the large-capacity energy storage system, DC high-voltage technology has become a technical trend. Through the increase of voltage level, energy saving, efficiency and performance improvement can be achieved. The 1500V voltage upgrade originated from photovoltaics, and now photovoltaics are involved in energy storage. However, the high-voltage evolution of energy storage PCS still has a long way to go, and some manufacturers have begun to optimize and push it to 2000V. The application of DC high-voltage technology forces the power electronic devices in energy storage converters to have higher withstand voltage levels and higher insulation strength to adapt to high-voltage working environments. In high-voltage environments, the heat dissipation design of power devices becomes more important. The pn junction temperature of power devices generally cannot exceed 125°C, and the temperature of the package shell does not exceed 85°C.

c.Networked energy storage systems require complex control algorithms, circuit designs and high power density energy storage converters

Unlike the essential characteristics of current sources in grid-forming energy storage systems, grid-forming energy storage systems are essentially voltage sources that can internally set voltage parameters to output stable voltage and frequency. Therefore, it is required that grid-forming converters simulate the characteristics of synchronous generators, providing support for voltage and frequency to enhance the stability of the power system. This control strategy necessitates that converters possess higher power density and more complex control algorithms, as well as higher-performance power devices and more intricate circuit designs to implement the control strategy. Effectively managing the heat generated by high power density and complex control strategies, while reducing the size and cost of the cooling system without compromising performance, has become a new challenge in thermal design.

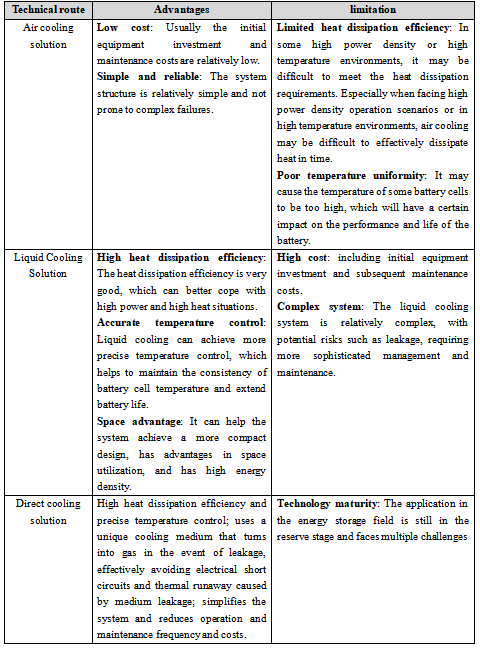

2- Comparison of common cooling solutions

The cooling solution for energy storage inverters has undergone significant iterative evolution in recent years, mainly reflected in the transition of cooling technology from traditional air cooling to liquid cooling technology.

a.Air cooling solution

Air cooling is the temperature control form used in the early stage of energy storage converters. It uses air as the medium and dissipates heat through fans and radiators. The air cooling solution improves heat dissipation efficiency by continuously reducing energy consumption, optimizing structure, and improving heat dissipation materials. At the 2.5MW power level, air cooling can still meet the requirements.

b.Liquid Cooling Solution

As the power density and energy density of energy storage systems continue to increase, liquid-cooled PCS uses coolant with high thermal conductivity as the medium. The coolant is driven by a water pump to circulate in the cold plate and is not affected by factors such as altitude and air pressure. The liquid cooling system has a more efficient heat dissipation efficiency than the air cooling system. The liquid cooling solution has a higher matching degree and has begun to be explored and popularized in the past one or two years.

In addition to the full liquid cooling energy storage solution, some manufacturers have launched energy storage direct cooling machines, which use phase change direct cooling and no water circulation. Direct cooling solutions are also entering the energy storage field.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference.

Thank you for your attention to Walmate.